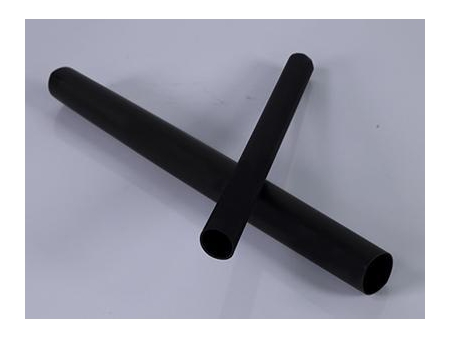

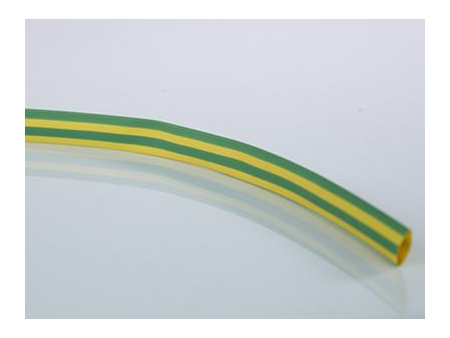

4:1 Dual Wall Heat Shrink Tubing (Item ZH52, Adhesive Lined Tubing, Offer Red / Green / Yellow Color)

Request a Quote

4:1 Dual wall heat shrink tubing is made of soft flame retardant polyolefin and hot-melt adhesive double layers without any harmful pollutants. The outer layer is polyolefin insulation flame retardant material and can provide insulation protection, wear resistance and anti-corrosion. The inner one is hot-melt adhesive and could avoid water and air leakage.

The product has a higher shrinkage rate and has a wide application range including insulation and sealing protection for various wire harness, marine wires and cables, and binding and fixing of metal tubing.

Main features| The lowest temperature of beginning shrinking | 70℃ |

| The lowest temperature of ending shrinking | 125℃ |

| Operating temperature | -45℃~125℃ |

| Heat shrinking ratio | 4:1 |

| Environmental standard | RoHS |

| Major material | EVA |

| Standard color | black (other colors can be ordered) |

| Specification | Inner diameter before shrinking | Size after shrinking(mm) | Package standard | |||

| Inner diameter Minimum(mm) | Inner diameter maximum | Total wall thickness | Adhesive layer wall thickness | Meter/coil or piece | ||

| Φ4.0 | 4.0 | 1.0 | 1.0±0.15 | 0.4±0.15 | 200 | |

| Φ6.0 | 6.0 | 1.5 | 1.1±0.15 | 0.4±0.15 | 100 | |

| Φ8.0 | 8.0 | 2.0 | 1.2±0.15 | 0.5±0.15 | 1.22 | |

| Φ12.0 | 12.0 | 3.0 | 1.4±0.15 | 0.5±0.15 | 1.22 | |

| Φ16.0 | 16.0 | 4.0 | 1.7±0.15 | 0.6±0.15 | 1.22 | |

| Φ20.0 | 20.0 | 5.0 | 2.0±0.25 | 0.6±0.15 | 1.22 | |

| Φ24.0 | 24.0 | 6.0 | 2.1±0.25 | 0.6±0.15 | 1.22 | |

| Φ32.0 | 32.0 | 8.0 | 2.4±0.25 | 0.7±0.15 | 1.22 | |

| Φ52.0 | 52.0 | 13.0 | 2.4±0.25 | 0.7±0.15 | 1.22 | |

| Property | Index | Test method |

| Tensile strength | ≥10.4MPa | ASTM D 2671 |

| Breaking elongation | ≥300% | ASTM D 2671 |

| Tensile strength after heat aging | ≥7.3MPa | 158℃×168h |

| Breaking elongation after heat aging | ≥100% | 158℃×168h |

| The axial changing ratio | -8%~+8% | ASTM D2671 |

| Flame retardant property | Self-extinguish within 30s | SAE-AMS-DTL-23053/5 |

| Disruptive strength | ≥15 MV/m | IEC 243 |

| Volume resistivity | ≥1014Ω=cm | IEC 93 |

| Property | Test method | Index |

| Softening point | ASTM E 28 | 85±3℃ |

| Water absorption point | ASTM D 570 | ≤0.2% |

| The minimum peel strength of PE | ASTM D 1000 | ≥120N/25mm |

| The minimum peel strength of AL | ASTM D 1000 | ≥80N/25mm |

Related products

3:1 Dual Wall Heat Shrink Tubing (Item ZH100, Adhesive Lined Tubing, Offer Yellow / Red / Green Color)

4:1 Dual Wall Flame Retardant Heat Shrink Tubing (Item FR52, Flexible Tubing, Offer Green / Red / Yellow Color)

Send Message

Other Products

Most Recent

More

Other Products

Videos