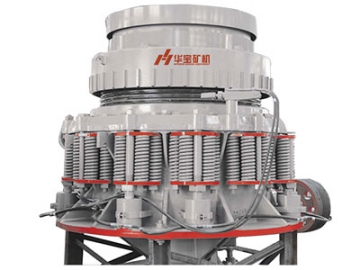

Cone Crusher, DMC Series

Cone Crushing Plant, Stone Crushing Machine, Stone Crusher, Aggregate Crushing Machine, Rock Crusher, Spring Cone Crusher

Comparing with jaw crusher, compound cone crusher has the advantages of low operating costs, large production capacity, easy adjustment and stable structure. The spring safety system of the crushing machine serves as an overload protection device. We adopt dry oil and water sealing form for the safety system to make the plaster powder and engine oil separate to guarantee a reliable performance.

Features of the cone crusher

1. This kind of cone crusher is distinguished for reasonable structure, reliable performance and low costs

2. It features powerful crushing ability, high production capacity and large volume

3. The reliable hydraulic system provides reliable overload protection

4. 2 kinds of coppers of this stone crusher can meet the crushing requirements of products with different dimensions

5. The adjustment and copper cleaning process is done automatically with the hydraulic system

Working principles of the compound cone crusher

When the cone crusher is working, the motor drives the eccentric bearing via the spring coupling, the transmission shaft and a couple of cone gear wheels. The crushing cone axis is forced to swing by the eccentric bearing bushing, which makes the mantle sometimes close to the bowl liner, and sometimes far away from the bowl liner. The raw materials are pressed, impacted and finally crushed in the copper.

Applications of the cone crusher

Compound cone crusher can be used for primary and secondary crushing of hard mineral stone, such as iron ore, copper ore, quartz, granite, basalt and dolerite, etc. Type of the crushing cavity is decided by the application of the materials. Standard type is for PYZ (secondary crush); middle type is for PYD (tertiary crush); short-head type is for primary and secondary crush.

This kind of stone crushing machine has been widely used in ore, metallurgy, chemistry, construction materials, road construction, hydroelectric and other fields to carry out primary and secondary crushing for various kinds of ores and rocks with different hardness.

| Model | Copper type | Max feeding diameter (mm) | Min dimension of the discharge opening (mm) | Motor power (kw) | Processing capacity | Weight (t) | |||||||||

| Closed-side setting (mm) | |||||||||||||||

| 6 | 10 | 13 | 16 | 19 | 22 | 25 | 38 | 51 | 64 | ||||||

| DMC1000 | C | 160 | 13 | 110 | 80 | 100 | 135 | 175 | 175 | 235 | 10.8 | ||||

| M | 115 | 10 | 110 | 65 | 75 | 90 | 120 | 150 | 150 | 10.8 | |||||

| F | 80 | 8 | 110 | 52 | 62 | 72 | 78 | 115 | 10.51 | ||||||

| EF | 50 | 6 | 110 | 50 | 55 | 65 | 70 | 102 | 10.51 | ||||||

| DMC1160 | C | 180 | 13 | 132 | 115 | ||||||||||

| M | 130 | 10 | 132 | 100 | 110 | ||||||||||

| F | 90 | 10 | 132 | 80 | 105 | ||||||||||

| EF | 60 | 6 | 132 | 60 | 74 | 105 | |||||||||

| DMC1300 | C | 200 | 16 | 185 | 150 | 180 | 200 | 230 | 310 | 390 | 22.3 | ||||

| M | 150 | 13 | 185 | 115 | 140 | 160 | 190 | 210 | 22.3 | ||||||

| F | 102 | 10 | 200 | 90 | 115 | 145 | 160 | 22.3 | |||||||

| EF | 70 | 8 | 200 | 88 | 110 | 135 | 155 | 22.3 | |||||||

| DMC1380 | C | 215 | 19 | 220 | 200 | 220 | 260 | 350 | 440 | 26.3 | |||||

| M | 160 | 16 | 220 | 155 | 180 | 200 | 220 | 26.3 | |||||||

| F | 115 | 13 | 220 | 150 | 190 | 210 | 230 | 26.3 | |||||||

| EF | 76 | 8 | 220 | 122 | 148 | 185 | 200 | 26.3 | |||||||

| DMC1650 | C | 235 | 22 | 250 | 265 | 310 | 420 | 525 | 580 | 36.5 | |||||

| M | 175 | 19 | 250 | 215 | 240 | 265 | 320 | 36.5 | |||||||

| F | 130 | 13 | 250 | 180 | 210 | 235 | 255 | 275 | 36.5 | ||||||

| EF | 90 | 10 | 250 | 148 | 178 | 200 | 220 | 36.5 | |||||||

| DMC1950 | C | 350 | 22 | 300 | 330 | 390 | 525 | 655 | 725 | 44.3 | |||||

| M | 203 | 16 | 300 | 230 | 270 | 300 | 330 | 44.3 | |||||||

| F | 140 | 13 | 300 | 185 | 225 | 265 | 340 | 44.3 | |||||||

| EF | 95 | 10 | 300 | 180 | 220 | 260 | 335 | 44.3 | |||||||