Frequency Inverter (for Cranes), AS600 Series

Features

1. Torque memory function: When braking, the inverter records the output torque so that when the machine starts again, the torque value is recreated to prevent sliding.

2. High startup torque

V/F control

Starting torque: 150%/1-3HZ (speed regulating range: 1:50 stable speed accuracy ±0.5%)

Open-loop vector control

Starting torque: 200%/0.3-0.5HZ (Regulating range: 1:200, precision of stable speed ± 0.2%)

Closed-loop vector control

Starting torque:200%/0min-1 (Regulating range: 1:1000, precision of stable speed ± 0.02%)

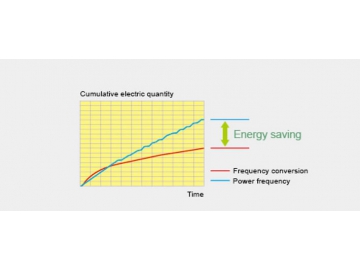

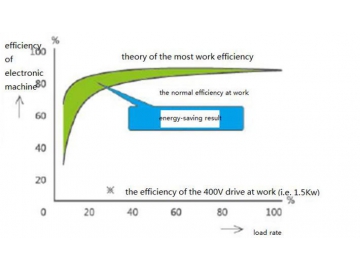

3. Weak-magnetic function

The inverter calculates maximum speed according to the load for more efficiency in lighter loads.

| Heavy load/super-heavy load | Heavy load | Super-heavy load |

| Overload toleration | 150% 1 min | 150% 1 min, 200% 2s |

| Application areas | Crane drifting, rotating mechanism etc. | Lifting mechanism of crane |

5. Supports several communication functions such as RS-485 and PROFIBUS-DP field network.

6. Comprehensive self-learning functions for static motors and rotating motors.

7. Designed to be compact with a wide voltage range, independent air ducts, terminal protection, overheating alerts, and power on self test function.

Technical specifications| Power input | Input power | 380V~460V (-15% ~ 10%), 3-phase power supply 220~240V optional 3-phase power supply |

| Input frequency | 45~65Hz | |

| Permissible voltage variation | Voltage unbalance factor < 3% | |

| Transient voltage dips | For 3-phase AC 380V~460V power supply, when input voltage < AC300V, under-voltage protection after 15ms (test at 85% load) |

| Power output | Motor output voltage | 0VAC~100% of input voltage, 3-phase power supply |

| Output frequency | V/F control: 0.00 ~ 300.00Hz Vector control: 0.00 ~ 120.00Hz | |

| Overload class | Heavy load (40 ℃ ): 150%, 1min; 200%, 3s | |

| Efficiency (full load) | 7.5kW and below ≥ 93%; 45kW and below ≥ 95%; 55kW and above ≥ 98% | |

| Precision of output frequency | ±0.01% (digital instruction -10 ~ 45 ℃ ) ±0.1% (analog instruction 25±10 ℃ ) |

| Environmental conditions | Location | Install vertically in a well ventilated electrical cabinet; horizontal or other installation method is not permitted. The cooling medium is air. Install in an environment without exposure to direct sunlight, dust, corrosive gas, inflammable gas, oil mist, steam and water drop . |

| Ambient temp. | -10 ~ 40℃ | |

| Temperature derating | Ambient temperature > 40 ℃ , for each 1 ℃ rise, rated output current reduces 1%, 50 ℃ at utmost | |

| Altitude | 1000m | |

| Height derating | > 1000 m , for each 100m lift, rated output current reduces 1% (3000 m at utmost) | |

| Ambient humidity | 5 ~ 95%, no condensation | |

| Vibration | Conform to following vibration conditions: 3.5 m/s2, 2 ~ 9Hz; 10 m/s2, 9 ~ 120Hz; | |

| Storage temp. | -40 ~ 70℃ | |

| Protection degree | IP00, IP20 |

| Others | Cooling type | Forced air cooling |

| Installation method | In cabinet | |

| Certification | CE |