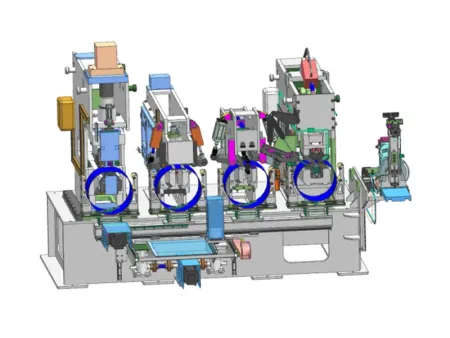

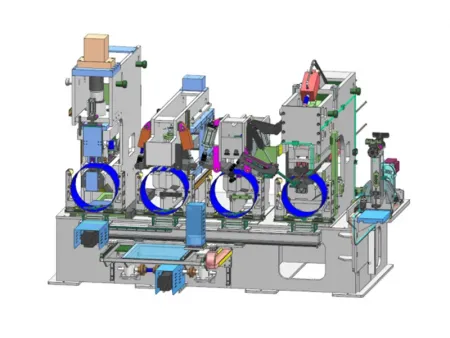

Trimming, Planishing, End Cutting and Re-rounding Machine

Request a Quote

Website: http://steelwheelmachines.com/1-3-trimming-planishing-end-cutting-and-re-rounding-machine.html

Weld trimmer, weld seam planisher, end cutting and re-rounder for handling steel wheel rim after butt welding operation

The trimming, planishing, end cutting, and re-rounding machine is a specialized piece of equipment for processing steel wheel rims after the butt welding stage. It includes multiple integrated components: weld trimmer, weld slag remover, weld seam planisher, and end cutting, along with an automated loading and unloading system, ensuring efficient handling of welded rims.

Component Functions

- Weld trimmer: Removes slag from both the inner and outer surfaces of the welded joint, creating a smooth and even surface

- Weld slag remover: Cleans up residual slag and debris from the welding process, preventing buildup and enhancing weld quality

- Weld seam planisher: Planishes and reinforces the welding seam for added durability of the weld

- Side trimmer (end cutting): Cuts off excess material from both ends of the welded joint, refining the rim to precise specifications

- Automated loading/unloading system: Integrates the operations of all four components, enabling seamless automation for increased wheel rim production efficiency

Process Flow Process Flow

- Trimming

- Planishing

- End cutting

- Re-rounding

Specifications

| Machine models | Weld trimmer | BZJ-400B | BZJ-500B | BZJ-800B |

| Weld slag remover | QZJ-400B | QZJ-500B | QZJ-800B | |

| Weld seam planisher | GYJ-400B | GYJ-500B | GYJ-800B | |

| Side trimmer (end cutting) | DQJ-400B | DQJ-500B | DQJ-800B | |

| Power supply | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ | AC 380V/3phase/50HZ | |

| Rated power | 50KW | 66KW | 78KW | |

| Wheel rim thickness | ≤5mm | ≤8mm | ≤10mm | |

| Wheel rim width | 200-400mm | 220-500mm | 240-800mm | |

| Wheel rim diameter | 350-480mm | 420-580mm | 475-1000mm | |

| Max. clamping force (planishing) | 60KN | 90KN | 120KN | |

| Max. planishing force | 60KN | 90KN | 120KN | |

| Max. cutting force (end cutting) | 280KN | 400KN | 530KN | |

| Cutting cylinder diameter | 125mm | 200mm | 220mm | |

| Servo motor power (automatic loading) | 13.2kW | 22.5kW | 22.5kW | |

Features

- The automated loading and unloading system is powered by three high-power servo motors, delivering fast operational speed and strong performance.

- All four main components share a single hydraulic station with the loading/unloading system, ensuring a well-organized and efficient layout.

- It supports both manual and automatic operation modes, allowing for easy adjustments and control.

- With a space-efficient and compact structure, it requires minimal floor space.

- The entire frame is constructed from thick steel plates, providing stability and durability.

- Its handwheel adjustment feature allows operators to quickly modify settings to accommodate different wheel rim sizes or specifications, or switch between various rim types.