104A Activated Alumina Antichlor

During the petrochemical production process, the chlorine from feed gas can poison various catalysts and adsorbents, and deactivate their adsorbing performance and catalytic performance. The presence of chlorine also seriously corrodes the device and equipment, which affects the normal production operations, making chlorine removal a necessary step. A solid antichlor is most often used for this process.

Chemical composition (wt%)

- AL2O3+addition agent: ≥93%

- 104A activated alumina antichlor can remove hydrogen chloride to protect the catalyst and adsorbent.

- It is applicable for the dechlorination of naphtha, natural gas, H2, N2, NH3, CO, CO2, and other feed gas types.

- Usually, there is a lot of HCl in liquid naphtha reformate, which will influence the operation of follow-up devices. This 104A activated alumina antichlor can continuously keep adsorbing HCl in any temperature environment.

Advantage

This 104A activated alumina antichlor features a wide operating temperature range, uniform activity under high temperature and low temperature, excellent water resistance, and it ensures the high anti-mobility of active component and chloride after reaction.

Service conditions

Temperature: 5-400℃

Pressure: atmospheric pressure -- 0.8Mpa

Space velocity : 1000-3000h-1

Bed height-diameter ratio: >3

Chloride removal rate: ≥99.9%

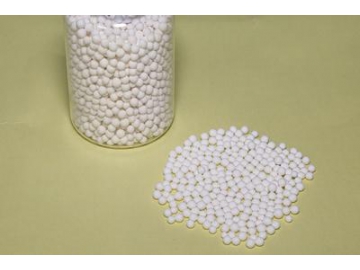

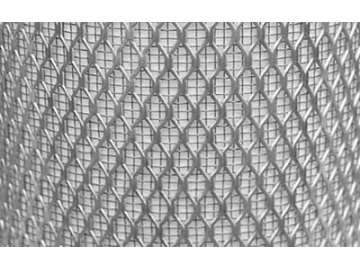

| Appearance | White spherical |

| Specification (mm) | 3.0-5.0 |

| Compressive strength( N/sphere ) | ≥120 |

| Specific surface area( m2/g ) | ≥130 |

| Bulk density (g/cm3 ) | 0.75-0.80 |

| Penetration of chlorine capacity | 50℃≥12% 350℃ ≥22% |

Package and notes

25kg/bags, 25kg/barrels packaging (lining plastic bag)

This product needs to be kept dry. It cannot be cast during the transportation, loading and unloading process, and must be airtight sealed when not in use.