Block Production Line With Curing Room

This product has been discontinued and removed from our shelves.

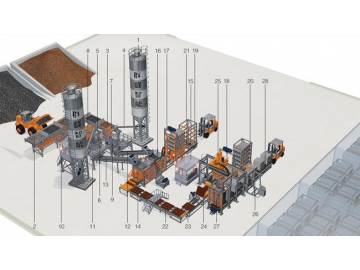

The making production line includes batching, automatic mixing, automatic molding/block producing, stacking, and forklift transferring. It requires nine workers.

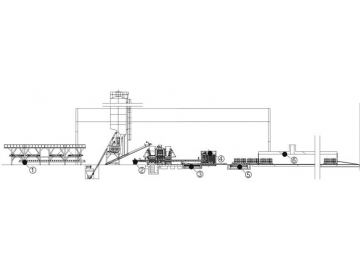

Simple Block Production Line- 1. Concrete Batch Machine

- 2. Cement and Concrete Mixer

- 3. Cement Scale

- 4. Cement Silo

- 5. Hollow Concrete Block Making Machine

- 6. Pigment Batching Machine

- 7. Pigment Mixer

- 8. Stacker

- 9. Control Room

- 10. Ferry Cart

- 11. Transition Cart

- 12. Kiln Cart

- 13. Curing Room

- 14. Pipeline for Steam

- 15. Kiln Door

- 16. Curing Room

- QFK-1 390x140x190mm concrete hollow block

- QFK-2 390x140x190mm concrete hollow block

- QFK-3 390x140x190mm concrete hollow block

- QFK-4 390x140x190mm concrete hollow block

- QFK-5 390x140x190mm hollow concrete block

- QFK-6 190x190x190mm hollow concrete block

Simple discreption of production sections of this concrete block production lines

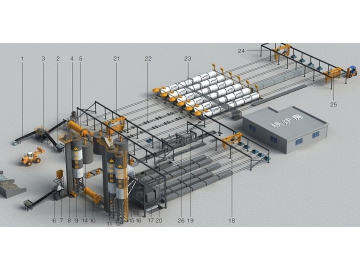

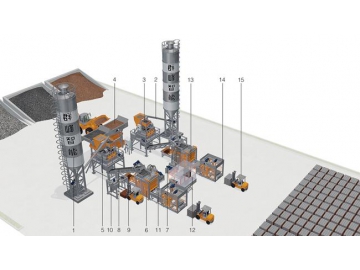

1. Concrete Mixing Station:

It consists of a cement silo (fly ash bin), automatic batching machine, dual horizontal shafts forced concrete mixer, cement scale and screw conveyor. It can batch and mix several kinds of aggregates automatically in accordance with the concrete ration set by the users beforehand. It will convey the material to the block making machine through the conveyer.

a. The automatic batching machine can weigh on two to four kinds of aggregates. Various models are available for users to choose from.

b. The cement in the cement silo will be conveyed to cement scale for weighing through the screw conveyor after it reaches the mixer, which not only controls the cement content accurately but also improves the quality of products. It will also reduce the working environmental pollution.

c. The color mixing system includes a PL800 Batching Machine, JQM500 Mixer (with lifting system), and pigment conveyor belt. The pigment will be automatically batched and mixed.

d. The mixing station is controlled by an independent PLC system. It is easy to operate and works reliably.

2. Forming System:

It is made up of model QFT10-15 block making machine and an automatic color feeding system. The forming system is technologic equipment integrating mechanism, hydraulic pressure and computer automatic control, featuring high working efficiency, reasonable design, compact structure, easy operation and convenient maintenance.

3. Transition Cart:

After curing, the curing rack will take the cured block out of the kiln car and the empty car will transfer to the transition cart. As the transition cart comes in front of the setting machine, it will push the empty kiln car to the setting machine.

4. Setting Machine:

Place the green blocks with pallets that formed by the block making machine one layer after another on the kiln car. The automatic pushing device in the transition cart will push another empty kiln car to the setting machine and transfer the previous kiln car (with green blocks) outside the setting machine.

5. Ramp Car:

Push the kiln car which loads green blocks to the ramp car with detent-type pawl. The ramp car will push the kiln car (with green blocks) to the curing room when it advances outside the curing room. The ramp car returns to the original position and transfer another kiln car to the curing room. After full loading, the ramp car will repeat the operation.

6. Curing Room:

The curing room is designed to cure the green blocks. The door of curing room opens as the green blocks are cured. The ramp car will push the kiln car (with green blocks) to the said curing room and its first kiln car (with cured blocks) will draw out of the curing room. Pick up the cured blocks and send the empty kiln car to the transition cart for the next operation circle.

| Base Line with Curing Room | ||

| No. | Name | Model |

| 1 | Cement Scale | |

| 2 | Screw Conveyor | φ219X5m |

| 3 | Automatic Batching Machine | PL1200-III |

| 4 | Concrete Mixer | JS750 |

| 5 | Block Making Machine | |

| 6 | Hydraulic Unit | |

| 7 | Pallet Feeder | |

| 8 | Blocks Conveyor | |

| 9 | Mold | |

| 10 | Conveyor Belt | |

| 11 | PLC | |

| 12 | Stacker | |

| 13 | Clin Car | |

| 14 | Ramp Car | |

| 15 | Transition Car | |

Qunfeng offers cinder block production line and concrete block manufacturing line including all sections of machines of making blocks, such as concrete batch plant, cement mixer, brick making machine, hollow block making machines, Qunfeng has other products related on the building materials, and building construction material recycling machines and equipment, and some street and road cleaning equipment.

Index

block making machine, brick machine, construction block, hollow concrete block, cinder brick