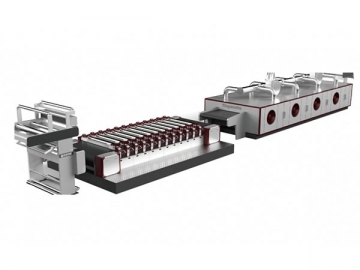

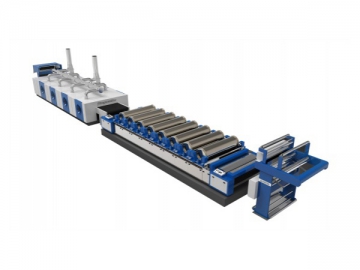

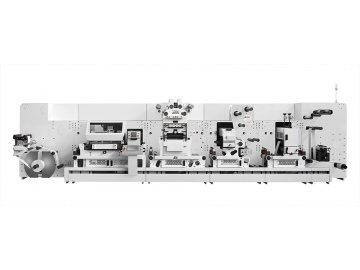

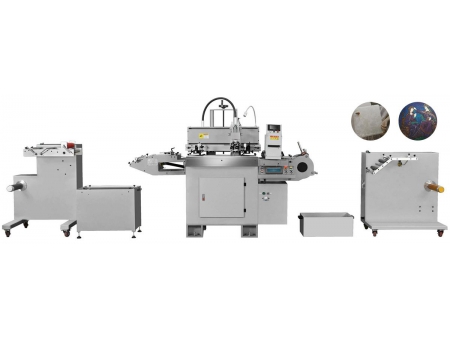

Rotary Screen Printing Machine (6188 Series Textile Printing Machine)

Specifications of Rotary Screen Printing Machine

| Printing width | 1620mm (180A) 1650mm (180B) 1850mm (200) 2050mm (220) 2250mm (240) 2400mm (260) 2450mm (265) 2600mm (280) 2650mm (285) 2800mm (300) 2850mm (305) |

| Printing workstation | 2 |

| Printing colors | 8 Color Printing 10 Color Printing 12 Color Printing 14 Color Printing 16 Color Printing |

| Repeat size | 640mm |

| Standard speed | 4-100m/min |

| Machine type | Left hand type / Right hand type |

| Printing method | Scraper/ magnetic rod |

| Type of screen head driving | Independent transmission |

| Registering accuracy | ±0.1mm |

| Registering adjustment range | Vertical: Unlimited, horizontal: ± 10mm, diagonal: ±3mm |

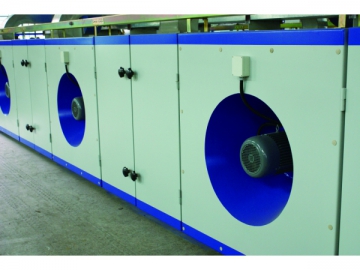

| Chamber of the dryer | Normal type, loose type |

| Heat source | Vapor, heat transfer oil, liquefied gas or natural gas |

| Working temperature of drying chamber | 130 ℃ (heat transfer oil or fuel gas) / 110 ℃ (vapor) |

Power System of Rotary Screen Print Machine

| Machine power supply | 380VAC(±5%) 50Hz 3PHASES |

| Lighting power supply | 220VAC(±5%) 50Hz 1PHASE |

| Protection degree | IP54 |

| Grounding mode | TN-S |

| Total power | ≈96kw |

Other Parameters

| Compressed air pressure | 0.6-0.8MPa |

| Water pressure | >0.2Mpa |

| Environmental temperature | 15 ℃ to 40 ℃ |

| Relative humidity | 50-80% |

Advantages of Rotary Screen Printing Machine

1. A patented single-beam lifting structure is adopted, so there is no need to lift the printing platform. The design effectively enhances the operation stability and printing accuracy of the machine.

2. A printing head driver is installed inside the beam, which well avoids chromatic aberration caused by blocked sizing agent, and protects the reduction gear and servo motor from corrosion and damage. Meanwhile, the design also helps to increases the reliability and lifespan of the textile printing machine. Adopting a printing head driver within beams is one of Jilong’s patented technologies.

3. Plane bearing is adopted for its printing head. Meanwhile, there is no oil fill hole located on the top of plane bearing. The design helps to prolong the bearing’s service life by 3-4 times.

4. Another patented part of the rotary screen printer is the enclosed chuck. It prevents the sizing agent from blocking the screen, and reduces maintenance work and cost.

5. The operation panel of printing head adopts one-piece waterproof design, which avoids water from percolating through the box. Therefore, it reduces the malfunction rate of the machine and increases its reliability.

6. Jilong has newly developed a sizing agent delivery structure, which helps to provide a clean and eco-friendly printing. Meanwhile, the design helps to reduces the contamination of size agent to printing platform and belt, and provides much convenience for machine maintenance.

7. Two sizing methods are offered, by scraper or magnetic platform. And customer could choose one from them according their requirement and preference.

8. The washing device adopts a drawer-type structure, allowing for effortless adjustment and cleaning. For better water removal effect, another water scraper is added.

9. A circular water cooling system and a cooling tower are all installed on the magnetic platform of the rotary screen machine, which effectively prevents the platform deformation caused by overheating.