Impact Crusher, PF Series

Stone Impact Crusher, Limestone Impact Crusher, Granite Impact Crusher, Aggregate Impact Crusher

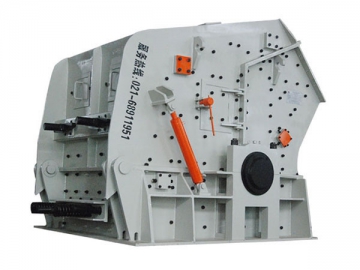

PF series impact crusher is used for crushing granite, basalt, limestone, and other products, with the material granularity ranging from 120mm to 300mm and crushing compression strength to be no more than 320mp. It features large crushing capacity, high crushing efficiency, and convenient maintenance. This kind of stone crusher is an ideal for high-grade road surface, railway, water conservancy project and electricity industries.

Features of the impact crusher

1. It features wide applications and good crushing result

2. With high crushing ratio, the materials processed by the crushing machinery are sharper than those crushed by cone crusher.

3. The central rotating impact bar is manufactured from high quality chrome to ensure that the crusher is abrasion resistant with a long life span.

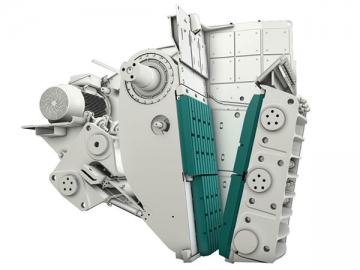

4. The impact crusher is able to be opened automatically with a hydraulic system, ensuring that the system is easy to be maintained.

Working principle of the impact crusher

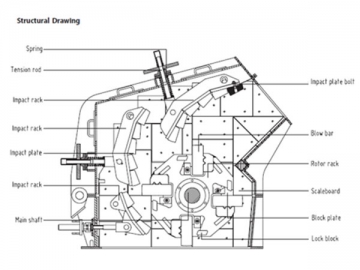

The impact stone crusher utilizes impact energy to crush materials. When the materials go into the area where the blow bars play a role, they will be crushed under the high-speed impact of the blow bars, and thrown to the impact plate above the rotor. Then they are rebounded to the blow bars, and being crushed again. The materials with different dimensions will be put into the chamber and crushed repeatedly. This process will continue until the materials are crushed to the required sizes and discharged from the opening of the impact crusher.

Applications of the crushing machine

PF series impact crusher has found wide applications in metallurgy, mining, cement, chemicals, ceramics, refractories, highway construction, water conservancy projects, building rubble, and sand processing industries, etc.

| Model | Feeding part dimension (mm×mm) | Max feeding granularity (mm) | Processing capacity (t/h) | Motor power (kw) | Weight (t) | Dimension (mm) |

| PF-1007 | 820×700 | 300 | 24-45 | 55 | 9.5 | 400×1558×2660 |

| PF-1010 | 1170×720 | 350 | 50-80 | 75 | 10 | 2532×1985×2196 |

| PF-1210 | 1090×465 | 350 | 80-130 | 110 | 14 | 2638×2037×2713 |

| PF-1214 | 1440×465 | 350 | 100-160 | 132 | 18 | 2580×2400×2810 |

| PF-1315 | 1532×560 | 500 | 140-200 | 200 | 19.3 | 2840×2748×2556 |

| PF-1316 | 1690×859 | 500 | 150-200 | 200 | 19.5 | 3096×2850×2667 |

| PF-1515 | 1580×696 | 500 | 220-280 | 280 | 28.5 | 3553×2835×3277 |

| PF-1620 | 1600×2080 | 800 | 350-450 | 560 | 47.5 | 3800×3350×3250 |

| PF-1822 | 1500×2250 | 1000 | 550-860 | 630 | 90 | 4260×3550×3640 |