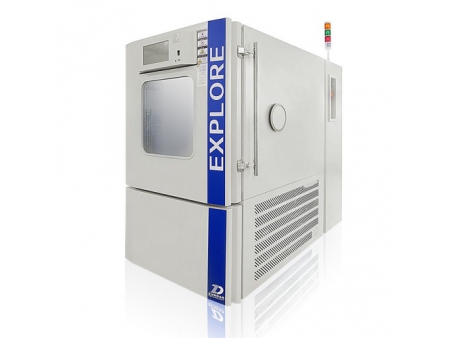

High Low Temperature and Humidity Test Chamber

Request a Quote

Features

- The refrigeration system includes a compressor from a well-known overseas brand with high-quality core components.

- The hot gas bypass technology is used to ensure economic and long-term stable running of the test chamber.

- The built-in lighting system is well matched with large multi-layer thermal insulation high-transmission observation window, which contributes to excellent visibility in the test space.

- Patented external pressure humidification system well matched with imported high-quality steam solenoid valve ensures high humidification efficiency and a wide range of damp heat curve.

- Linear conversion of various temperature and humidity algorithms brings excellent equipment performance.

- The stainless steel liner with mirror finish is high-end, stylish and rust resistant.

- The environmental test chamber can control both temperature and humidity within a wide range.

Relative humidity: 15%~95%RH (no heat source in working space during damp heat test).

Temperature range:10℃ ~95℃ (low temperature auxiliary system can be added to satisfy the requirements for low temperature).

Technical Parameters

| High and Low Temperature and Humidity Test Chamber -70℃ ~ 180℃ /10%~98%RH/2℃/min | |||||

| Specifications & Model | |||||

| Internal Volume | 250L | 500L | 1,000L | ||

| Overall Dimensions | Internal Dimensions (W×D×H) | 550×600×750mm | 800×750×850mm | 1,000×1,000×1,000mm | |

| External Dimensions (W×D×H) | 800×1,500×1,650mm | 1,050×1,830×1,850mm | 1,250×2,080×2,050mm | ||

| Performance | Temperature Range | -70℃~ 180℃ ( 210℃ can be achieved,but it is not included in indicator measurement) | |||

| Fluctuation Range of Temperature | ≤ 0.5℃ (no-load steady state) | ||||

| Temperature Deviation | ≤ 2℃ (no-load steady state) | ||||

| Humidity Range | 10%RH~98%RH (10℃~ 95℃) | ||||

| Relative Humidity Deviation | ≤±3%RH(>75%RH,no-load steady state) ≤±5%RH(≤75%RH,no-load steady state) | ||||

| Fluctuation Range of Relative Humidity | ≤±3%RH | ||||

| Temperature and Humidity Control Mode | Hot gas bypass technology | ||||

| Temperature Change Rate | Heating rate:Not less than 2℃/min (-55 ℃~ 85℃,average value in the entire process,measured at the air outlet,no load) Cooling rate:Not less than 2℃/min ( 85℃~-55℃,average value in the entire process,measured at air outlet,no load) | ||||

| Constitution | Shell Material | Cold-rolled steel sheet with plastic powder coating | |||

| Material of Test Area | SUS304 stainless steel with mirror finish,the gaps are fully welded by TIG (tungsten inert gas arc welding) | ||||

| Heater | Nichrome wire heater | ||||

| Cooler (Dehumidifier) | Mechanical dehumidification | ||||

| Circulating Fan | Centrifugal fan | ||||

| Air Dryer (Optional) | Decreasing dew point by adsorption freezing drying air | ||||

| Water Supply | Water Supply Mode | Automatic and manual water supply | |||

| Water Supply Tank | 24L | ||||

| Refrigeration System | Refrigeration Mode | Two-stage cascade refrigeration | |||

| Refrigerating Machine | Piston compressor | ||||

| Refrigerant | Environment-friendly refrigerant HFC R404a R23 | ||||

| Equipment Requirements | Ambient Conditions | 5~ 30℃/relative humidity≤85%RH | |||

| Power Supply | 380V±38V/50Hz N G | ||||

| Total Weight of Tank | Approx. 600kg | Approx. 800kg | Approx. 1,000kg | ||

| Applicable Standards | GB/T 2423.1-2008 Environmental Testing for Electric and Electronic Products-Part 2:Test Methods-Tests A:Cold GB/T 2423.2-2008 Environmental Testing for Electric and Electronic Products-Part 2:Test Methods-Tests B:Dry Heat GB/T 2423.3-2008 Environmental Testing for Electric and Electronic Products-Part 2:Testing Method- Test CaB:Damp Heat,Steady State GB/T 2423.4-2008 Environmental Testing for Electric and Electronic Products-Part 2:Test Method-Test Db:Damp Heat,Cyclic (12h 12h cycle) GB/T 2423.34-2008 Environmental Testing for Electric and Electronic Products-Part 2:Test Methods-Test Z/ AD:Composite Temperature/Humidity Cyclic Test GJB 150.3A-1986 Environmental Test Methods for Military Equipment High Temperature Test GJB 150.4A-1986 Environmental Test Methods for Military Equipment Low Temperature Test GIB 150.9A-1986 Environmental Test Methods for Military Equipment Damp Heat Test | ||||

| Applicable Measurement Standard | JJF 1101-2003 Calibration Specification for the Equipment of the Environmental Testing for Temperature and Humidity | ||||

Notes:

- The range of temperature and humidity above is the results tested at an ambient temperature of 20℃ (room temperature) or cooling system water temperature of 25℃ and with no load.

- Measurement was made as per the test method of IEC 60068-3-6: 2001/GB/T 2424.6-2006/JMT K09: 2009 based on the effective space formed with a distance of 1/10 to each edge in the internal box.

- The pictures and specifications above are for reference only. The specific specification is subject to quotation.

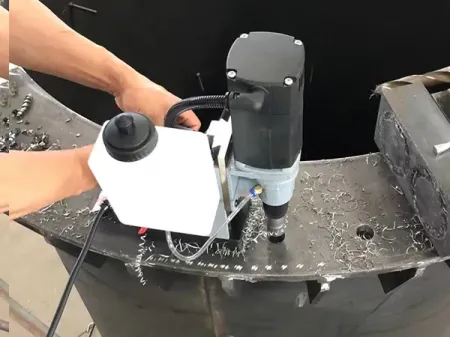

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos