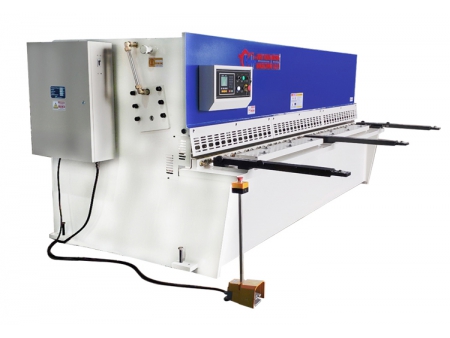

QC12K(Y) Hydraulic Swing Beam Shear

When designing the QC12K(Y) hydraulic sheet metal shear, we decided to have a back gauge that uses an ABBA ball screw and counting function for cutting is also added in the metal shearing machine.

-

Max cutting Thickness (mm)

6-25

-

Max. cutting width (mm)

3200-6000

-

Worktable Panel Thickness (mm)

30-60

-

Wallboard Thickness (mm)

30-80

| Type | Max. Cutting ThickNess | Max. Cutting Width | Worktable Panel ThickNess | wallboard ThickNess | thickNess of KNife Rest Upstand | Anti-Strength of Plate | Stroke Times | Throat Depth | Blade Length | Main Motor |

| 4 | 2500 | 35 | 25 | 35 | 450 | 17 | 130 | 2600 | 5.5kW | |

| 4 | 3200 | 35 | 25 | 35 | 450 | 14 | 130 | 3300 | 5.5kW | |

| 4 | 4000 | 35 | 25 | 35 | 450 | 14 | 130 | 4100 | 5.5kW | |

| 4 | 6000 | 45 | 30 | 45 | 450 | 8 | 130 | 6040 | 7.5kW | |

| 6 | 2500 | 40 | 30 | 40 | 450 | 14 | 130 | 2600 | 7.5kW | |

| 6 | 3200 | 45 | 30 | 40 | 450 | 11 | 130 | 3300 | 7.5kW | |

| 6 | 4000 | 50 | 35 | 50 | 450 | 11 | 130 | 4100 | 7.5kW | |

| 6 | 5000 | 50 | 40 | 50 | 450 | 8 | 130 | 5050 | 11kW | |

| 6 | 6000 | 50 | 40 | 50 | 450 | 8 | 130 | 6040 | 11kW | |

| 8 | 2500 | 45 | 35 | 45 | 450 | 14 | 130 | 2600 | 7.5kW | |

| 8 | 3200 | 50 | 35 | 45 | 450 | 11 | 130 | 3300 | 7.5kW | |

| 8 | 4000 | 50 | 40 | 50 | 450 | 10 | 130 | 4100 | 7.5kW | |

| 8 | 5000 | 50 | 45 | 50 | 450 | 8 | 200 | 5050 | 11kW | |

| 8 | 6000 | 55 | 45 | 50 | 450 | 5 | 130 | 6040 | 11kW | |

| 10 | 3200 | 50 | 45 | 50 | 450 | 10 | 130 | 3300 | 11kW | |

| 10 | 4000 | 50 | 45 | 50 | 450 | 8 | 175 | 4100 | 11kW | |

| 12 | 2500 | 50 | 45 | 50 | 450 | 11 | 175 | 2600 | 18.5kW | |

| 12 | 3200 | 50 | 50 | 50 | 450 | 10 | 175 | 3300 | 18.5kW | |

| 12 | 4000 | 50 | 50 | 50 | 450 | 8 | 175 | 4100 | 18.5kW | |

| 12 | 5000 | 60 | 50 | 60 | 450 | 6 | 200 | 5075 | 22kW | |

| 12 | 6000 | 60 | 50 | 60 | 450 | 6 | 200 | 6040 | 22kW | |

| 16 | 4000 | 60 | 50 | 50 | 450 | 6 | 200 | 4100 | 18.5kW | |

| 20 | 6000 | 80 | 70 | 80 | 450 | 4 | 100 | 6040 | 30kW | |

| 25 | 6000 | 100 | 80 | 100 | 450 | 5 | 200 | 6040 | 45kW |

-

The metal shear display the position of the back gauge in real time, which is convenient for the operator.

The metal shear's multi-stages programing function allows for automatic operation of the back gauge and continuous positioning, achieving the position of back gauge automatic adjustment with excellent precision.

-

The counting function of cutting can display the shear amount in real time, and when the power turned off, it can record the back gauge's position, program and parameters.

-

The back gauge uses an ABBA ball screw, ensuring the accuracy of the back gauge's position, and makes the machine's processing accuracy higher.

- Ball Bed

- Hold Down Cylinders

- Union Connector

- Blade Gap Clearance Adjust

- Manual Refuel Device

- Back Gauge Motor