Roll Forming Machine (for Step Tile)

Brief Description

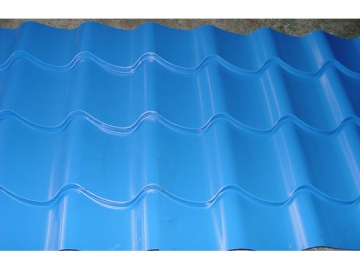

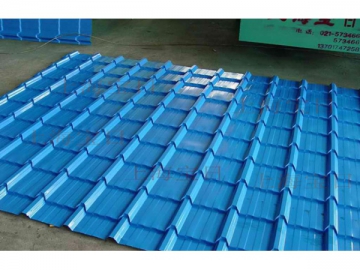

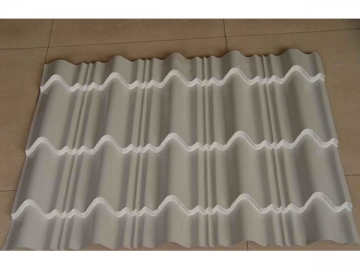

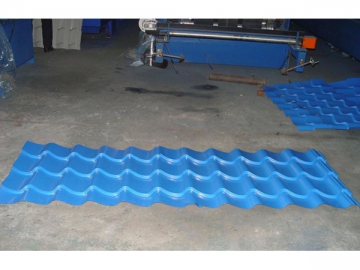

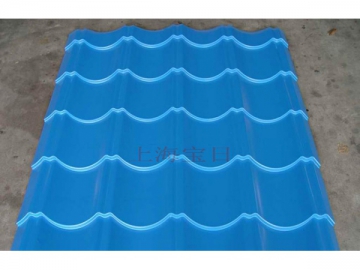

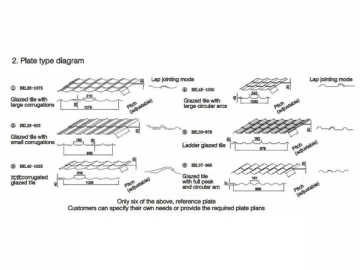

Roof step tiles eliminate the labor spent in laying down tiles one after another manually on your roof. Baori step tile roll forming machine produces a variety of roofing sheets, including step tiles, corrugated tiles and so much more. Our roll former can be customized to produce a specific tile profile.

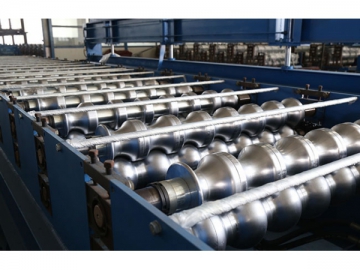

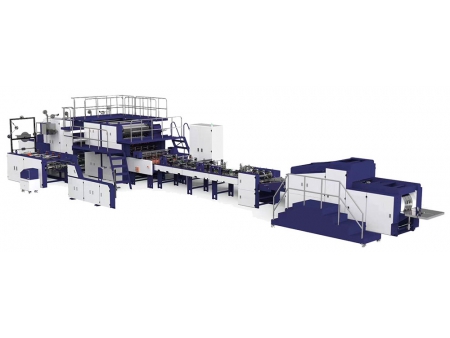

The BRF series steptile roll former is a piece of automatic metalworking equipment that allows ease of handling and delivers high efficiency, safety, and reliability. As coils of color-coated steel strips pass through a consecutive series of roller die sets, they are bents incrementally into customer-desired profiles. The entire process is computer controlled and hydraulically powered to perform cutting and bending operations.

Patented cutting blade design, coupled with reliable hydraulic components, results in steady running. Roller dies are precision ground on a NC lathe to very tight tolerances under 0.02mm. Die parts are pieced together by experienced workers for rugged and safe performance.

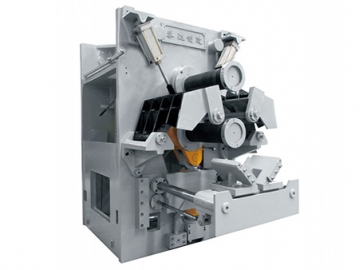

- Cutting Head

- Rotary Roller Dies

This roll forming equipment can be customized.

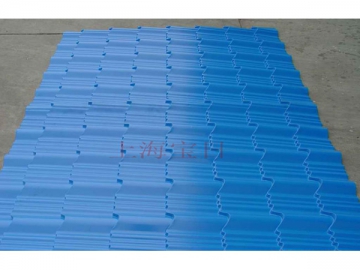

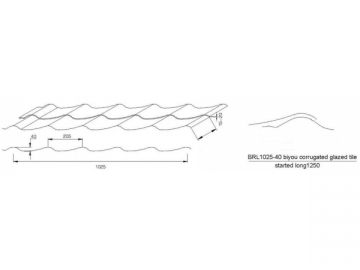

Example Step Tile Profile

Technical Specifications

1. Material thickness: 0.35~0.6mm

2. Color coated steel width: 1000 mm, 1200 mm, 1250 mm (as per customer requirements)

3. Power supply: AC380/50-60Hz/3PH

4. Total power: 12.8kw~16.8kw

5. Production line speed: 0-8m/min (hydraulic transmission, step less speed adjustment)

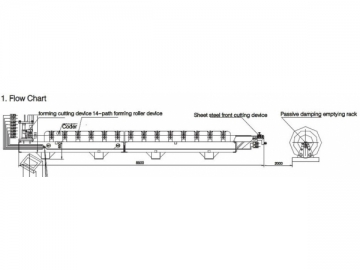

6. Overall dimensions: (8-10)m x 1.5m x 1.8m

7. Payoff stand: passive damping force, 5T

8. User interface: Canadian brand Xinje and PWS6600S-SA Taiwan brand QuanYi

9. PLC automatic controller: Canadian brand Xinje

10. VFD: Japanese brand YiNeng and VFD-M Taiwan brand DELTA

11. Encoder: OVW2-20MHC-2000 Japanese brands, measurement range (0-10m)

Guarantee Period and Installation

1. Guarantee period: one year for roll forming equipment

2. Installation, commissioning and training: Our Company will send two engineers for free-of-charge field installation, commissioning and the training.

- Roll former

- Roll former

- Roll former

- Roll former

- Hydraulic Cutting

- OMRON (JAPAN) Digital Decoder

- Touch-screen control panel

- Uncoiler