Synchronous Fiber Chip Sealer

I. Application

The GYXKT0812 synchronous fiber chip sealer is a synchronous sealing machine used to seal the surfaces of roads, waterproof bridges, and seal coat other construction projects. Asphalt binders are sprayed synchronously with fibers and aggregate for maximum contact and cohesion.

Our synchronous fiber chip sealer is independently developed by our company, earning proprietary intellectual property rights for its advanced technology. Improving on the design of the GYKT0616B asphalt sealer, this road maintenance equipment has double rows of asphalt nozzles and fiber spray systems so it can spread chips without lifting the hopper, making it ideal for narrow spaces such as bridges and curves. A strong agitator in the asphalt tank prevents the asphalt rubber from separating into liquids and solids. The synchronous fiber chip sealer incorporates mechanical, electric and hydraulic systems in one machine, simplifying the operating process.

II. Technical Parameters of the Synchronous Fiber Chip Sealer| Model | |

| Chassis model | |

| Power of auxiliary engine | 70kW |

| Spray width | 3500mm |

| Spray volume | 0.5 ~ 3.0kg/m2 |

| Aggregates size | 3 ~ 25mm |

| Asphalt tank capacity | 8m3 |

| Aggregates hopper capacity | 12m3 |

| Heater | imported diesel heater |

| Spray medium | Base asphalt, modified asphalt, cutback asphalt, emulsion |

| Length of fiber | 30/60/120mm |

| Fiber-spray volume | 30 ~ 90g/m2 |

| Unladen weight | 23500kg |

| Full load weight | 50000kg |

| Machine dimensions | L×W×H=11130×2500×4000mm |

| Overall dimensions | L×W×H=14550×2500×4000mm |

III. Components and Structures of the Synchronous Fiber Chip Sealer

Our fiber chip sealer consists of an asphalt spray system, chip spreading system, fiber spray system, electrical control system and auxiliary engine system.

Asphalt Spray System

The asphalt system includes an asphalt tank, heating unit, hydraulic unit, control unit and spray unit.

1. Asphalt Tank: The outer layer is made of a stainless steel frosted board while the middle layer is insulated, keeping the heat from the fire tubes and coils inside. A gas control valve bank drives major and minor cycles and prevents asphalt from overheating.

2. Heating Unit: An imported burner features high burning efficiency, low oil consumption, fast heating speed and safe operation. Asphalt in the pipelines will be effectively heated.

3. Hydraulic Unit: Using hydraulic pumps, motors, and other components from famous international brands to provide the synchronous fiber chip sealer with reliable driving performance.

4. Control Unit: Radar and encoder accurately detects the speed of the vehicle and asphalt pump to control precise spraying and recommend vehicle speed when a spray volume is set. The radar, encoder and main circuit switch are all imported.

5. Spray Unit: Each nozzle is turned on and off by an air valve. Specially designed pipeline provides uniform pressure and spraying.

Chip Spreading System

This system consists of a material hopper, feed gate controller and spreader. Two stilling cones installed in the hopper guarantee that aggregate is driven to the double spiral distributor via the feed belt. The feed gate uses a 20-way control system and the roller has a special anti-skid design which prevents aggregate from skidding on the roller after dropping. The double spiral distributor delivers aggregate to a lower hopper that is 3,500mm wide. Gravity and friction against the roller pull the aggregate down for even spreading. This technology is patented at Patent No. ZL200520078495.6. This synchronous fiber chip sealer uses aggregate that is between 3 to 25mm in size.

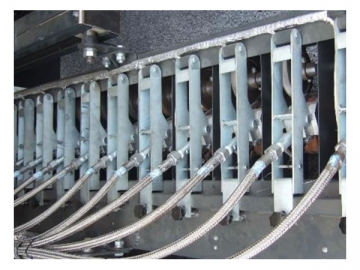

Fiber Spray System

The fibers are cut and crushed before being spread evenly out between the two layers of asphalt binders, which knits a mesh structure so they stick to the binders. This structure makes the sealing coat more tensile, shear, and resistant to shock and impact. The protective mesh has high elasticity and strength and is laid between the surface coat and the new roadbed.

Electrical Control System

1.The PLC system provides accurate spray parameters depending on the project and detects real-time conditions so parameters of the synchronous fiber chip sealer can be adjusted as needed.

2.Easy to switch between manual and automatic modes.

3.Adjustable asphalt spraying and aggregate spreading width. Automatic alert when aggregate reaches minimum and maximum limits.

4.Limit switches control the width of the spreader to prevent damages.

5.Automatic alerts for low heat oil, maximum and minimum levels of the hopper, and minimum levels for asphalt levels.

Auxiliary Engine System

The 70kw auxiliary engine has the advantages of strong power and reliability, supplying power to the hydraulic and electrical systems to maintain stable performance of the synchronous fiber chip sealer.

IV. Advantages of the Synchronous Fiber Chip Sealer

1. Because the synchronous fiber chip sealer can spread chips without lifting the hopper, it can be used in narrow spaces such as under bridges and at curves.

2. Automated functions control the spreader’s expansion and amount of asphalt spray.

3. Double spiral distributor pushes the aggregate to a 3,500mm wide lower hopper, in which gravity pulls the aggregate down for even spreading.

4. The fiber chip sealer reduces the intensity of labor, initial cost investment, and human resources while improving work efficiency and quality.

5. High precision nozzles maintain uniform and reliable spraying of aggregate sized 3mm to 25mm.

6. The anti-corrosive and durable insulation layer keeps the insulation index at no more than 20℃ for 8 hours.

7. The nozzle carrier is foldable and its clearance from the ground can be adjusted. The fiber spray unit swings horizontally.

8. Remote control features make the chip sealing equipment easy and convenient to operate.

9. The electric control system and hydraulic pressure-constant system allow spraying to begin as soon as the truck starts.

10. Improvements based on customer feedback keep this sealcoating equipment reliably performing, easy to operate, and cost-effective.

| No. | Name | Brands | Remarks |

| 1 | Asphalt pump/1 | Johnson | Belgium |

| 2 | Heat oil pump/1 | Johnson | Belgium |

| 3 | Auxiliary engine/1 | YUCHAI | China |

| 4 | Cylinder/20 | AIRTAC | China |

| 5 | Shaft coupling of combustion engine/1 | KTR | Germany |

| 6 | Reducer/2 | Guomao | China |

| 7 | PLC/1 | Omron | Japan |

| 8 | Solenoid valve/34 | Fsh | China |

| 9 | Velocity radar/1 | Dickey-john | USA |

| 10 | Inverter/1 | Mingwei | China Taiwan |

| 11 | Touch Screen/1 | Xinjie | China |

| 12 | Low voltage control component/1 | Schneider | Germany |

| 13 | Encoder/1 | Koyo | Japan |

| 14 | Burner/2 | RIELLO | Italy |

| 15 | Cycloid motor/4 | Eaton | USA |

| 16 | Cycloid motor/6 | SAUER-DANFOSS | USA |

| 17 | Hydraulic cylinder/5 | Steady | China |

| 18 | Constant pressure volume adjustable hydraulic pump/1 | SAUER-DANFOSS | USA |

| 19 | Solenoid directional valve/7 | ARGO-HYTOS | Germany |

| 20 | One-way throttle valve/4 | TOGNELLA | Italy |

| 21 | Radiator/1 | AKG | Germany |

| 22 | Double-way valve/1 | WALVOIL | Italy |

| 23 | Cartridge overflow valve/1 | Haihong | China |

| 24 | Double directional throttle valve/3 | TOGNELLA | Italy |

| 25 | Double directional regulating valve/3 | TOGNELLA | Italy |

| 26 | Twin hydraulic lock/5 | TOGNELLA | Italy |

| 27 | Adjustable prior bypass valve/1 | BONDIOLI&PAVESI | Italy |

| 28 | Gear motor/1 | TJ | China |

| 29 | Gear pump/1 | TJ | China |

| 30 | Air compressor/1 | JAGUAR | China |

Projects

Simulating Construction Projects at the Factory

Fiber Spray Unit

Fibers

Project for the Russian Federal Highway M55

Working Results