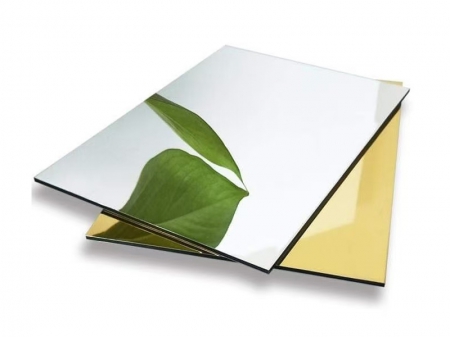

PVDF Aluminum Composite Panel, ACP Panel

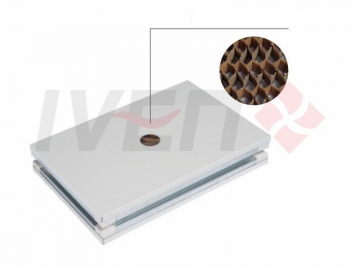

Aluwedo® PVDF Kynar 500 Aluminum composite panels are produced with automatic machine using advanced technique introduced from German. There are two layers of high-strength aluminum sheets made from A1100, A3003 and A5052. The panel is formed by low density polythene (LDPE) and DUPONT adhesive film under high temperature and high pressure. The outermost aluminum sheet has been coated with 70% fluoro polymer resin-based coating. And the innermost aluminum sheet is protected with an anti-corrosion primer coat.

Manufacturing Techniques

1. Cold mounting techniques only

2. Saw cutting

3. Routing

4. Die cutting (punch press die set is required; not a steel rule die)

5. Forming curves

6. Grooving

The production line of Aluwedo signage high gloss finish aluminum composite panel is a complex work integrating various machining, assembling and inspection procedures. For more details please download ALUWEDO processing guidelines.

Raw Material

a. High strength aluminum alloy A1100, A3003, A5052

b. LDPE core

c. Surface coating: PVDF coating, Kynar 500 (Paint supplier: Valspar, Nippon, PPG, Becker, etc.), and Dupont Adhesive film

Specifications and Dimension

1. Standard Specification

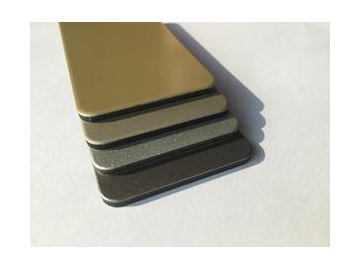

a. Thickness: 3mm (0.12"), 4mm (0.16"), 5mm (0.2"), 6mm (0.24")

Recommended thickness: 4mm (0.16")

b. Width: 850mm – 2000mm (34" – 80")

Recommended width: 1220mm (48.8"), 1250mm (50"), 1500mm (60"), 2000mm (80")

c. Length is as required

d. Aluminum thickness: 0.3mm (0.012") – 0.5mm (0.02")

e. *Custom width and length is available upon request (subject to the minimum order quantities)

2. Recommended Dimension

1220mm (4ft)* 2440mm (8ft)* 4mm (0.16")* 0.5mm (0.2")

1500mm (5ft)* 3050mm (10ft)* 4mm (0.16")* 0.5mm (0.2")

3. Tolerance (mm)

Thickness: ±0.2

Width: ±0.2

Length: ±3

Diagonal: ±3

Excellent torsion strength

With varieties of advanced equipment and strict control, ALUWEDO panel features high strength, excellent torsion strength, large bending strength, and excellent weather resistance

Easy processing and installation

ALUWEDO panel is easy to be processed for its light weight (3.5-5.5kg/sqm). All of the cutting, milling, planning, slotting, side-folding and curving operations can be easily fulfilled with simple tools used for processing timber and metal. Indoor and outdoor decoration can be implemented simultaneously so as to raise working efficiency and cutting working time

Excellent impact resistance

ALUWEDO features good impact resistance, toughness, and bending rigidity. It will not be damaged when suffering from sand blown by wind

Excellent weather resistance

ALUWEDO panel coated with fluoro-carbon (PVDF) resin features good tightness, strong adhesion, alkali resistance, and powdering resistance. It can be used for 20 years without getting fade

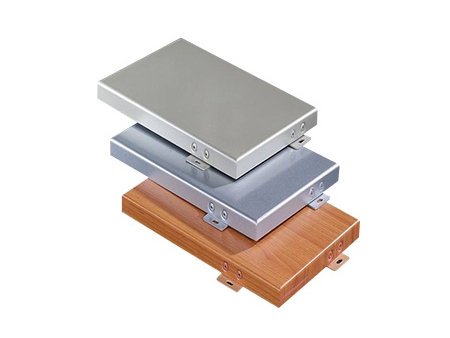

Various color available

Dealing with the surface of aluminum material, and with the application of Henkle technology, it makes the paint and ALUWEDO stamped with a very strong even force. Various color are prepared for option

Easy maintenance

ALUWEDO panel needs to be maintained and cleaned after several years' use. Only neutral cleanser and water is needed. It will as bright as new after cleaning

Panel Specifications

Architects and building owners should determine which panel specification is needed, along with the painting color. In order to ensure the paint performance expected for a given application, AAMA 2605 is the high-performance exterior specification. A paint meeting this specification would be a 70% fluoro polymer resin-based coating. These finishes exhibit outstanding resistance to humidity, color change, chalk, gloss loss and chemicals. An application for this finish would include monumental architectural projects. We choose Kynar 500 for the PVDF coating which allows for 15 years exterior guarantee.

| Testing item | Standard | Result |

| Unit weight | ASTM D792 | T 4mm=5.5kg/m2 |

| Thermal expansion | ASTM D696 | 24-28 |

| Thermal deformation temperature | ASTM D648 | 115 ℃ |

| Thermal conduction | ASTM D976 | 0.102kcal/m.hr ℃ |

| Flexural rigidity | ASTM D393 | 14.0*10^5 |

| Impact resistance | ASTM D732 | 1.64kgf |

| Adhesive strength | ASTM D903 | 0.77kg/mm |

| Flexural elasticity | ASTM D790 | 4030kg/mm2 |

| Shear resistance | ASTM D732 | 2.7kgf/mm2 |

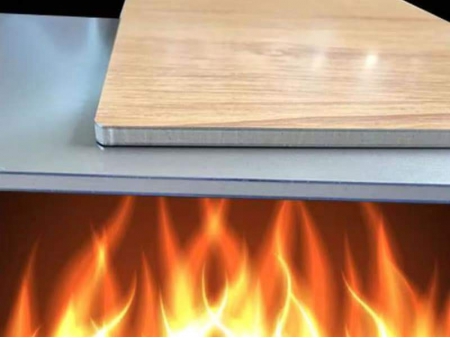

| Fire propagation | ASTM E84 | qualified |

| Wind-pressure resistant | ASTM E330 | passed |

| Properties against water | ASTM E331 | passed |

Applicable Standards

1. American Architectural Manufacturers Association (AAMA) - AAMA 2605 Voluntary Specification

2. Performance Requirements and Test Procedures for Superior Performing Organic Coatings on Aluminum Extrusions and Panels

ASTM International

1. ASTM C297 Standard Test Method for Tensile Strength on Flat Sandwich Constructions in Flat Plane

2. ASTM C976 Standard Test Method for Thermal Performance of Building Assemblies by Means of a Calibrated Hot Box (Withdrawn 2002)

3. ASTM D635 Standard Test Method for Rate of Burning and/or Extent and Time of Burning of Self-Supporting Plastics in a Horizontal Position

4. ASTM D696 Standard Test Method for Coefficient of Linear Thermal Expansion of Plastics Between -30°C and 30°C With a Vitreous Silica Diameter.

5. ASTM D1037 Standard Test Method for Evaluating Properties of Wood-Base Fiber and Particle Panel Materials

6. ASTM D1781 Standard Test Method for Climbing Drum Peel for Adhesives

7. ASTM D1929 Standard Test Method for Determining Ignition Temperature of Plastics

8. ASTM E8 Standard Test Method for Tension Testing of Metallic Materials

9. ASTM E72 Standard Test Methods for Conducting Strength Tests of Panels for Building Construction

10. ASTM E84 Standard Test Method for Surface Burning Characteristics of Building Materials

11. ASTM E108 (Modified) Standard Test Methods for Fire Tests of Roof Coverings

12. ASTM E283 Standard Test Method for Determining the Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Difference Across the Specimen

13. ASTM E330 Standard Test Method for Structural Performance of Exterior Windows, Curtain Walls, and Doors by Uniform Static Air Pressure Difference

14. ASTM E331 Standard Test Method for Water Penetration of Exterior Windows, Curtain Walls, and Doors by Uniform Static Air Pressure Difference

15. ASTM E413 Standard Classification for Rating Sound Insulation