PVC-Based WPC Profile Extrusion Line (One-Step)

Wood Plastic Composite Extrusion Line, Plastic Extruder, PVC Profile Extruder, PVC Pipe Extrusion Machine

-

WPC Wall Panel Mold

-

WPC Profile Shaping Die

-

WPC Profile Haul-off unit & Cutting Machine

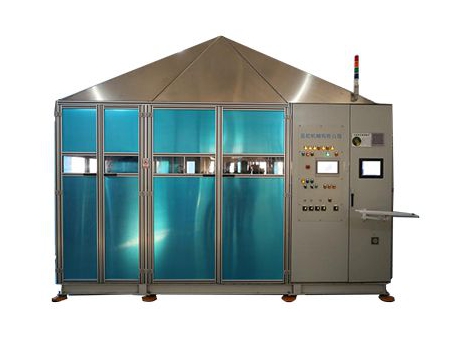

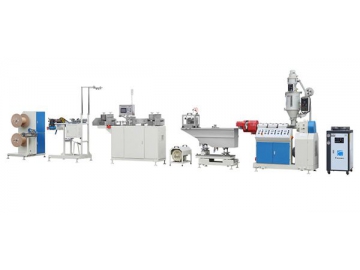

Our extrusion line for WPC profile employs the unique WPC processing technique and prescription of Zeqi. Taking different material proportion, and different models of WPC twin-screw extruders, accompanied with the corresponding vacuum sizing machine, tractor, sawing machine, material arranging device, and other auxiliary equipment, the extrusion line can produce WPC profiles with different sections or usages.

The tractor is specially developed by Zeqi, possessing stable performance, high reliability, and large tractive force.

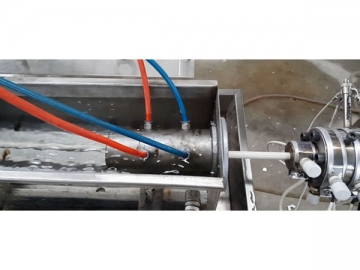

A swirl cooling system introduced for the vacuum sizing machine for the convenience of cooling and molding.

The sawing machine runs synchronously with the tractor. It is designed with the function of cutting automatically at a certain length. Dust recycling device is equipped for the WPC profile extrusion system.

-

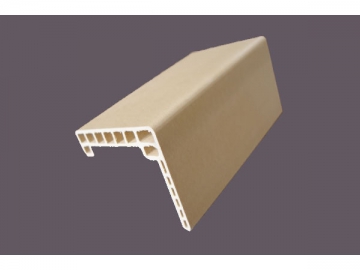

Extruding WPC baseboard

-

Eco wood WPC board

-

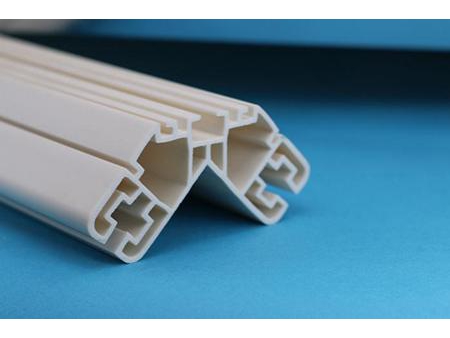

WPC Door Frame Profile

-

Indoor applications of WPC Profiles(One-Step)

Raw materials:

PVC powder, wood powder, other additives

Applications:

for producing indoor decoration materials like baseboard, door edge, louvres, furniture frame, door frame, window cover, staircase handrails, floors, timber, wood-plastic pipe, etc.

Processing Technique – One-Step Extrusion

a. Principle

One step extrusion means removing the pelletizing step from the extrusion line, and directly letting the raw materials to be mixed and extruded in the equipment. This technique shows advantages of high efficiency, good plasticizing result, and low production cost. It is suitable for indoor decoration materials whose surface need to be precisely treated and don’t have to bear heavy load.

Presently, one step extrusion is generally applied in extruding PVC products. But, to accomplish a one-step extrusion line, the requirements upon material prescription, feeding device, molds, extruder, as well as operators’ skills are rather high.

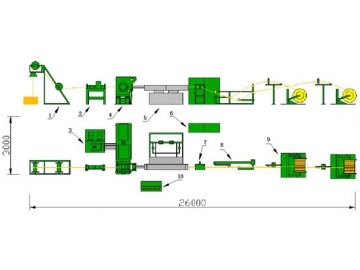

b. Diagram

Raw material mixing (wooden powder PVC powder other additives) →WPC production line (conical twin screw extruder →mold →vacuum calibrator→ haul off unit→ fixed length cutting →stacker) → finished products →qualified products →surface treatment →packing →storing

↘waste →crushing →recycling

| Model | |||

| Screw diameter (mm) | 51/105 | 65/132 | 80/156 |

| Main motor power (kw) | 18.5 | 37 | 55 |

| Maxi width (mm) | 180 | 240 | 300 |

| Max extrusion capacity (kg/h) | 40-140 | 50-250 | 180-320 |