Air Source Heat Pump

Introduction

The WARM air source heat pump operates according to the principle of the reverse Kano cycle. The pump is driven by electrical motor and uses refrigerant to transform the heat energy in the air into available energy to heat the cold water and maintain a comfortable temperature.

| Item\model | |||||

| Heat capacity | kw | 23 | 46 | 92 | 184 |

| Rated power | Kw | 5.01 | 9.96 | 19.87 | 39.56 |

| Rated water yield | L/h | 494 | 988 | 1976 | 3952 |

| Maximum temperature of outlet water | 20~60℃ | ||||

| Applicable environment temperature | -25~43℃ | ||||

| Compressor | Type | High efficiency full closed scroll compressor | |||

| Refrigerant type | R22 | ||||

| Control mode | CPU control (line control, centralized control and networked control) | ||||

| Power supply | V/Hz | 380V 3N~50Hz | |||

| Maximum current(A) | 14 | 27 | 54 | 108 | |

| Protection device | High and low voltage switch, temperature control probe, overcurrent protection device, water break protection device | ||||

| Type of heat exchanger | High-efficiency plate heat exchanger/high-efficiency spiral tube heat exchanger/high-efficiency shell and tube heat exchanger | ||||

| Fan | Type | Axial flow fan 380V-50Hz with steel aluminum alloy blades | |||

| Power (kw) | 0.37 | 0.37 × 2 | 0.37 × 4 | 0.37 × 8 | |

| Connecting pipe size | Inlet(outlet) water | G1 | G1-1/2 | G2-1/2 | G2-1/2 × 2 |

| Outline size | Length × width× height(mm) | 812 × 812 × 1151 | 1523 × 812 × 1151 | 1604 × 1523 × 1151 | 3208 × 1523 ×1268 |

| Unit weight | Kg | 215 | 350 | 680 | 1250 |

1. Main components

1). The whole system adopts 304 stainless steel panels with excellent resistance to corrosion, high temperatures and oxidation. This allows the machine to better adapt to different environmental conditions.

2). High efficiency internal thread copper tubes are used for the heat exchanger, which are of reliable quality and high heat transfer efficiency.

3). Closed structure design with higher efficiency and more stable water temperature.

4). Using the fully closed copeland vortex compressors of world-renowned brands, the energy efficiency is higher.

5). 3D low noise aluminum alloy fan blades that pass the static balance test and are of lower noise, lighter and more durable.

6). Unique monoclinic heat exchanger, through professional CAE analysis, realizes more uniform wind velocity distribution at a higher efficiency.

7). International famous brand Danfoss expansion valves are used to significantly improve the efficiency of the unit.

8). Special high-efficiency spiral tube heat exchanger for heat pumps

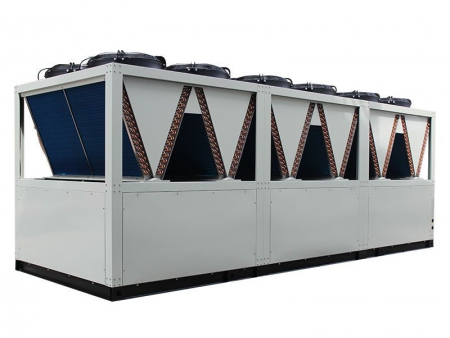

2. Unique V shape design

All of the air source heat pump units jointly developed by warm and a foreign research and development center adopt closed V type structure, which is currently the only one in China. The structure is a V type structure of side air intake form and three-layer heat transfer design, which has high heat transfer ability, to ensure that the heat exchange of the equipment has reached the limit (the heat generated by the compressor and other accessories gets effectively recycled). In addition, the free seamless stitching of the units can be realized, without need for special distance between them, and not affected by the wind direction and other external environment, the efficiency is more stable.

3. Excellent control

Advanced intelligent fuzzy control: the equipment has automatic fault judgement, processing, alarm display, timing switchgear and other functions. The unit can automatically control the opening of the main engine and the circulating pump according to the water temperature of the water tank, as well as realizing remote monitoring or computer monitoring.

4. Multiple protection

The unit has multiple protection functions, including high and low pressure, high temperature, lack of phase, overload, antifreeze and other protection functions.

The products all pass the system holding pressure tests, halogen tests, second halogen tests, performance tests, etc. before leaving the factory, so as to ensure each machine is 100% qualified.

5. Precise design and patented frosting technology

The local climate is simulated, and the parameters in the computer chip of the unit are adjusted accurately to achieve stable operation and the lowest energy consumption possible.

The unique RTR intelligent defrosting technology: the six parameters, including evaporator coil temperature, ambient temperature, system high pressure, system low pressure, inlet water temperature and outlet water temperature, can be used to comprehensively judge the frosting and defrosting states of the coil. This allows the designers to accurately execute the procedure of entering and exiting defrosting.

1. Lingyue series (normal temperature)

The unit is specially designed by WARM for large and medium commercial units in East China and other regions where the minimum winter ambient temperature is within -15[GF1] ℃. at the ambient temperature within -10 ℃, without any auxiliary heat source, the unit can output 60℃ domestic hot water.

2. Polaris series (ultralow temperature)

The unit is specially designed by our company aiming at large and medium commercial units in North China and other regions where the minimum winter ambient temperature is within -25 ℃, which can normally output hot water at that temperature.

3.Smart series

The unit is a thermal cycle unit developed by our company, which can directly heat running water to the required temperature, as well as effectively avoiding all kinds of problems that arise in cold climates and water pressure fluctuations, so that the water temperature is constant and the water flows as desired.

4. Lingli series(domestic use)

The unit is a small domestic hot water unit developed by our company. It uses white PP material and the mold is formed at once. The design is seamless and rust resistant. It is used to support the water supply for bathrooms, kitchens, and any other commercial and residential water installations.

5. High temperature heat pump

WARMcompany has currently developed a high temperature air source heat pump unit adopting a two-stage condensation technique, thus the outlet water temperature can reach 75℃.