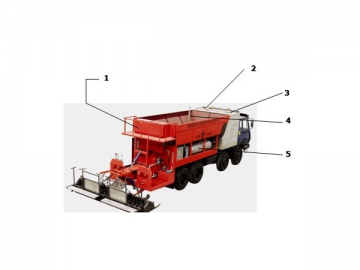

Fiber Slurry Paver

The HGY5311TFC intelligent fiber slurry paver improved with additional fiber unit is mainly applied to treat the pavement diseases, like friction resistance reduction, cracks and ruts, for improving the performances of road in anti-slide and waterproofing, evenness and travelling comfort. This equipment can be widely used in construction of slurry seal, modified slurry seal, micro surfacing and fiber micro-surfacing.

This equipment is a new type of our independent patented product for road maintenance, reaching the international advanced level. This product is tested and optimized for many years, which is an ideal machinery for slurry seal, micro-surfacing and fiber micro surfacing constructions.

Profile

2. Fiber Cutting

3. Mixer

4. High-pressure Cleanser Pump

5. Additive Tank

6. Water Tank

7. Aggregates

2.Asphalt Emulsion Tank

3.Auxiliary Engine

4. Hydraulic Power System

Paving Box

Adjustable Biaxial Rectangular

Paving Box (paving width of 2.5~4.3m)

V-shaped Paving Box for Ruts Repair

| Product Model | |

| Chassis Model | |

| Engine Power | 110kW / 2300rpm |

| Aggregates Bin Volume | 12 m3 |

| Emulsion Tank Volume | 4 m3 |

| Water Tank Volume | 4 m3 |

| Additive Tank Volume | 600 L |

| Filler Tank Volume | 2 × 0.5 m3 |

| Discharging Volume of Mixer | max.3.5T/min |

| Fiber amount | max.3.5kg/min (1.3 ‰ ) |

| Minimum Vehicle Speed | 1 km/h |

| Width of Paver | 2.5 - 4.3 m |

| Overall Dimensions | 11690 × 2496 × 3490 (mm) (L × W × H) |

| Chassis | ZZ1317M3867D1 |

| Auxiliary Engine | Cummins |

| Asphalt Pump | China Hengxing |

| Hydraulic Pump | USA PARKER |

| Hydraulic Valve | Germany BUCHER |

| Hydraulic Motor | Denmark DANFOSS / USA White |

| Hydraulic Reversing Valve | Germany ARGO-HYTOS |

| Vibrating Motor | Italy ITALVIBRAS |

| Reduction Gear | Tianjin SEW |

| Main Electric Unit | Japan OMRON |

| Text Display | Japan OMRON |

| Electric Relay | Germany WEIDMULLER/Japan IDEC |

| Mixer | China SG |

| Paving Box | China SG GYJT2543 |

Chassis

Special designed chassis

SinoTruk Styer 8×4 type chassis adopted by our fiber slurry paver shows good mobility with 290HP engine and large loading capacity of 31 tons.

Two-speed gearbox

The truck stays at high gear when it returns to the stock yard and moves to another yard, then changes into low gear in construction. The minimum vehicle speed can be kept at 1 km/h, which is enough to pave at low speed for construction quality and travel at high speed for improving working efficiency.

Feeding System

2. Emulsion feeding subsystem

3. Water supply subsystem

4. Aggregates feeding subsystem

5. Additive feeding subsystem

The materials feeding system of the fiber slurry paver consists of five parts: aggregates feeding subsystem, emulsion feeding subsystem, water supply subsystem, fillers feeding subsystem and additive feeding subsystem.

Aggregates feeding subsystem

This subsystem consists of aggregates bin, stilling cone, feed gate, belt conveyor, drive system and feeding shortage alarm device.

1. Aggregates bin has a large volume of 12m³, reducing the frequency of shuttling between stock yard and construction spot, which is to prolong construction time, reduce the amount of transverse joints and improve working efficiency and construction quality.

2. Vibrating stilling cone avoids sliding and bridging caused by belt overburdening and effectively improves the stability of conveying aggregates.

3. Independent belt conveyor is easy to be assembled and disassembled. Its adjustable structure is convenient for belt governing and maintenance.

4. Adjustable feed gate makes the feeding volume easy to regulate as required of various construction conditions.

5. Strong hydraulic motor drives stable conveying. Infinitely variable control mode keeps accurate and convenient operations. Advanced velocity-measuring feedback sensor can control conveying accurately.

6. Accurate feeding shortage alarm device monitors aggregates conveying in the all-range construction, which is the double insurance of construction quality control.

Emulsion feeding subsystem

This subsystem mainly contains emulsion tank, emulsion pump, control valve, pipeline and drive system.

1.Corrosion-resistant emulsion tank with large volume of 4m³ greatly improves the working efficiency.

2.Emulsion pump with steady flow of rotor positive-displacement pump is featured by high efficiency and steady flow rate. Advanced velocity sensor is equipped to realize accurate emulsion supply volume. The pump of jacket heating meets the needs of severe working conditions. The pump also can pump oil by it self which make fuel in construction convenient.

3.Air control valve: air control angle seat of famous foreign and domestic brands offers strong guaranty to automatic control.

4.Corrosion-resistant pipelines are all made of the qualified stainless steel to prolong the service life.

5.Strong hydraulic motor of famous foreign and domestic brands drives conveying stably. Infinitely variable control will realize accurate control and operations.

Water supply subsystem

This subsystem mainly contains water tank, water pump, flow meter, control valve, pipeline and power drive system.

1.Water tank with large volume of 4m³ greatly improves the working efficiency.

2.Stable centrifugal water pump is featured by stable performance and long service life.

3.Digital display target flow meter can measure the water flow rate accurately and blend materials accurately.

4.Air control angle seat supplied by famous foreign manufacturers offers strong guaranty to automatic control.

5.Corrosion-resistant pipelines are all made of high quality stainless steel for a longer service life.

6.High-pressure cleanser and refill water device for paving are equipped to facilitate the routine cleansing and maintenance and the special construction technology.

Fillers feeding subsystem

This system can work with two types of fillers, which is meaningful to various construction conditions. Internal fluffer and spiral feeder guarantee the stable and precise discharging volume.

Additives feeding subsystem

All the components and parts of the fiber slurry paver are stainless steel made. The device is pneumatic powered, showing simple structure and stable performance. Glass rotameter reads flow rate, reliable to monitor and easy to operate.

Fiber feeding subsystem

This system includes fiber rolls revolving tank, fiber cutting device, fiber feeding device and independent power and control system.

Radial cutting wheels blades in parallel outward. The clearance between two blades is the length of cut fiber. This special structure with small size is easy to deliver fiber, accurate to measure the fiber amount and uniform in fiber length; the fiber is cut and blown into mixer by compressed air.

Mixing System

This mixing system of fiber slurry paver adopts the biaxial spiral blade to mixing and conveying, with features of high rotating speed, strong power and good effects of beating. High abrasion blade effectively ensures efficient construction. The freely adjustable rake angle of mixer improves mixing effects and meets the needs of construction on the roads with different slopes. Maximum discharging volume is 3.5t/min, which is suitable for any construction requirements.

Paving System

1. Automatic telescopic paver does not only suit any kinds of roads, but also regulates with appropriated camber according to the road conditions in construction.

2. Double-row spiral propeller is capable of paving and re-tempering, with great effects to preventing slurry from segregating.

3. The underside of hard wearing skid shoes is made of hard alloy wearing materials to prolong its service life.

4. Strong hydraulic motor of famous foreign and domestic brands drives conveying stable. The rotating speed and directions can be governed freely according to various construction technologies.

Power System

The power system of the fiber slurry paver is consisted of engine and hydraulic system.

Engine

Cummins water-cooled engine with rating power of 110kw/2000rpm is equipped with turbocharger of strong power, stable performance and reliable quality.

Hydraulic System

The hydraulic pump, hydraulic motor, hydraulic control valve are all famous foreign brands, which offers strong guaranty to the system. The power unit of this system is controlled by two groups of triple pump, which supplies independent power to the respective executive system and keeps them interference free.

Control System

The collective control system situates all the hand operations within the operating platform. It is also easily capable of starting or stopping operations with one single switch. PLC of premium brand is applied to make the system more intelligently. This equipment is equipped with a complete system of display and alarm devices, convenient to construction.

Advantages

1. This fiber slurry paver is our patented product exceeding the level of same kind products both around home and abroad.

2. Large power engine is applied to pave breaking modified asphalt of high viscosity.

3. Large storage bin of 12m3 is equipped to improve working efficiency.

4. The maximum mixing volume of 3.5t/min fits for different width, depth and technologies of construction.

5. Fiber feeding unit of optimized design regulates fiber feeding amount accurately and uniformly, easy in operation.

6. The fluid storage tanks and pipelines are all made of stainless steel to prolong the service life of this equipment.

7. Key parts are all famous international brands so as to guarantee reliability and stability.

8. This equipment applies centralized control to the whole machine, with complete function of display and alarm, humanized design and easy operation.

9. The chassis is equipped with two speed gear box which realizes a perfect combination of travelling at high gear and construction at low gear.

10. The optimized product offers strong guaranty to the construction quality and prolongs its service life.

11. The paver looks elegant in appearance.