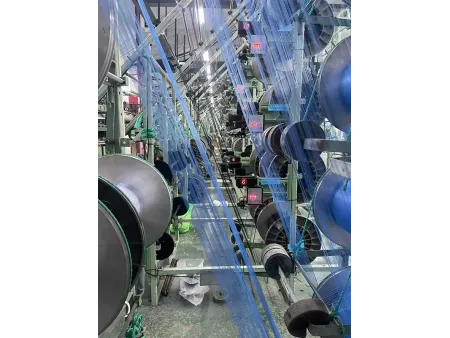

Integrated Active Warp Tension Control Warping Creel

Request a Quote

The integrated active warp tension control warping creel is made of aluminum alloy, with a plug-and-play system that operates independently of machine settings or loom type. It offers precise and stable performance across various weaving applications.

Features- Individual Motor Control: Each yarn position is driven by its own motor, allowing simultaneous forward and reverse rotation. One unit can rotate clockwise while another rotates counter-clockwise, ensuring accurate yarn balance even under complex configurations.

- Real-Time Feedback: Provides continuous monitoring and automatic warp-tension correction to maintain consistent tension levels.

- Highly-stable feeding: Delivers fewer stops, reduced idle time, and minimal manual adjustments, contributing to smoother production and improved efficiency.

- Enhanced Fabric Consistency: Ensures stable tension for elastic fabrics, jacquard tapes, and technical tapes, improving overall fabric uniformity.

- Reduced Waste and Higher Output: Helps reduce labor cost, increase production efficiency, and lower defect and scrap rates.

- Reliable Solution: Whether upgrading an existing warping system or configuring a new production line, the integrated active warp tension control warping creel delivers accurate, fully automated tension control that supports modern, high-precision weaving operations.