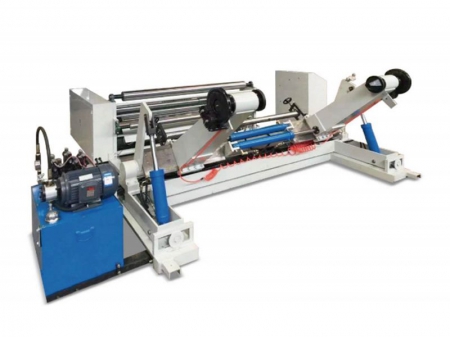

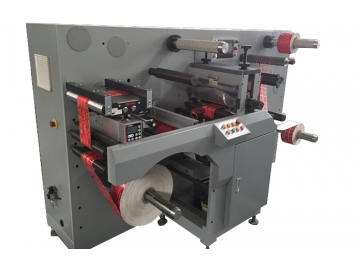

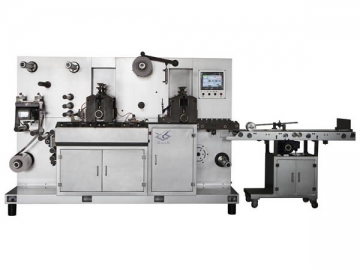

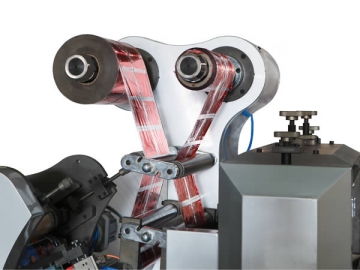

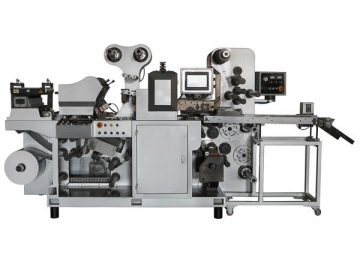

Print Finishing Equipment (Die Cutting Machine, Slitter Rewinder)

Equipped with a U.K. Trio motion control system and register sensor, this die cutting machine prints labels and tags, and can finish unwinding, rotary die cutting, slitting and rewinding in one process.

Advantage

1. Ourslitter rewinder can work in either semi rotary mode or full rotary mode. In the semi rotary mode, only flexible dies, rather than magnetic cylinders, need to be changed to process different labels, making for easier and faster operation.

2. An applied web guide enables this print finishing equipment to load paper smoothly.

3. With its compact structure and easy operation, our intermittent die cutting machine is a convenient machine for businesses needing fast, efficient and accurate cutting.

Technical Data of Multifunctional JXMQ-320 Die Cutting Machine| Slitting speed | 90m/min |

| Die cutting speed | 70m/min (intermittent) |

| 90m/min (full rotary) | |

| Max. web width | 320mm |

| Max. unwinding diameter | 600mm |

| Max. rewinding diameter | 600mm |

| Die cutting length | 200-450mm (intermittent) |

| 250-550mm (full rotary) | |

| Overall dimension (L×W×H) | 3.5×1.3×1.52m |

| Machine weight | 2500kg |

| Voltage | 380V/3P |

| Power consumption | 12kW |

| Configuration | 1. One rotary die cutting station with waste rewinder 2. One lamination station with waste rewinder for over-laminated film 3. One slitting station with magnetic clutch and two 3" rewind air shafts 4. One 3" unwind air shaft with tension controller 5. Label/length counter 6. One register sensor 7. Eight rotary knives 8. Blower fan to remove trimmed paper 9. Web guide (made in USA) 10. Cold foil stamping station with UV light 11. Conveyor belt |

| Die cutting speed | 70m/min (intermittent) |

| 90m/min (full rotary) | |

| Max. web width | 320mm |

| Max. unwinding diameter | 600mm |

| Max. rewinding diameter | 600mm |

| Die cutting length | 200-450mm (intermittent) |

| 250-550mm (full rotary) | |

| Overall dimension (L×W×H) | 3.5×1.3×1.52m |

| Machine weight | 2500kg |

| Voltage | 380V/3P |

| Power consumption | 12kW |

| Configuration | 1. One rotary die cutting station with waste rewinder 2. One lamination station with waste rewinder for over-laminated film 3. One 3" unwind air shaft with tension controller 4. Label/length counter 5. One register sensor 6. Eight rotary knives 7. Blower fan to remove trimmed paper 8. Web guide (made in USA) |

| Slitting speed | 90m/min |

| Die cutting speed | 70m/min (intermittent) |

| 90m/min (full rotary) | |

| Max. web width | 320mm |

| Max. unwinding diameter | 600mm |

| Max. rewinding diameter | 600mm |

| Die cutting length | 200-450mm (intermittent) |

| 250-550mm (full rotary) | |

| Overall dimension (L×W×H) | 3.5×1.3×1.52m |

| Machine weight | 2500kg |

| Voltage | 380V/3P |

| Power consumption | 12kW |

| Configuration | 1. One rotary die cutting station with waste rewinder 2. One lamination station with waste rewinder for over-laminated film 3. One slitting station with magnetic clutch and two 3" rewind air shaft 4. One 3" unwind air shaft with tension controller 5. Label/length counter 6. One register sensor 7. Eight rotary knives 8. Blower fan to remove trimmed paper 9. Web guide (made in USA) |

| Slitting speed | 90m/min |

| Die cutting speed | 70m/min (intermittent) |

| 90m/min (full rotary) | |

| Max. web width | 320mm |

| Max. unwinding diameter | 600mm |

| Max. rewinding diameter | 60 mm |

| Die cutting length | 200-450mm (intermittent) |

| 250-550mm (full rotary) | |

| Overall dimension (L×W×H) | 3.5×1.3×1.52m |

| Machine weight | 2500kg |

| Voltage | 380V/3P |

| Power consumption | 12kW |

| Configuration | 1. Two rotary die cutting stations with waste rewinder (the second station fits for in mold labeling and sheeting) 2. One lamination station with waste rewinder for over-laminated film 3. One slitting station with magnetic clutch and two 3" rewind air shafts 4. One 3" unwind air shaft with tension controller 5. Label/length counter 6. One register sensor 7. Eight rotary knives 8. Blower fan to remove trimmed paper 9. Web guide (made in USA) |

Related Names

Blank Label Cutting Machine | Rotary Slitting Machine

.jpg)