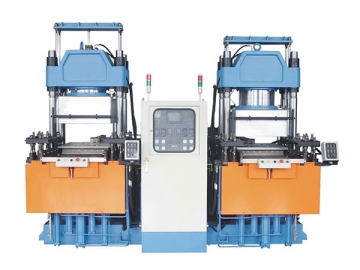

Plastic Injection Molding Machine

Injection Molding Machine, Plastic Injection Press, Plastic Forming Machine, Plastic Injection Moulding Machine

Huatai SZL series C-frame (vertical) plastic injection machine is suitable for producing automobile rubber seal strip, seal strip joint, and other plastic molds. It features compact structure, high injection efficiency, uniform heating, and accurate plastic molding result, being able to shaping complex-shaped products easily. SZL series products have passed CE and ISO9001: 2001 standards, and have been widely exported to many countries like Japan and Thailand.

Main Features

1. Precision injection & close-loop control

2. Compact structure & high efficiency

SZL series plastic injection press is designed with compact structure and stable components. It shows reliable performance and high production efficiency.

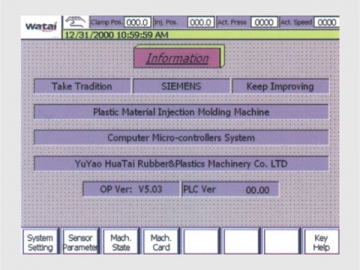

3. Intelligent control & multi modes

Huatai has employed both intelligent security system and multi working modes for this plastic injection molding machine. With the human-machine interface displaying the working condition in real time and alarming the errors automatically, users will get to know how the machine runs and set the parameters easily. If there is a wrong operation, the plastic molding machine will refuse to execute the order and give users some tips. The production information is recorded automatically.

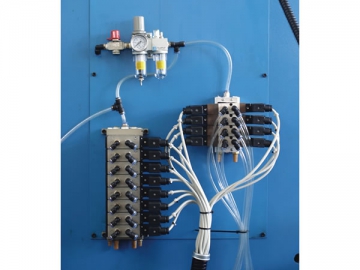

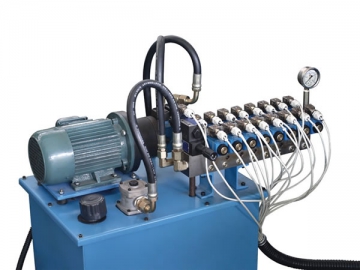

4. Multi optional supporting systems

For this plastic injection molding machine, users can additionally equip it with hydraulically assisted system, pneumatically assisted system, clamping unit, ejection unit, integrated clamping and ejection unit, double stations, injection control for hot runner, temperature mold for hot runner, and remote control system.

5. Optional computer control system

We have prepared 3 kinds of computer control systems respectively from Siemens, Techmation and Mitsubishi for option.

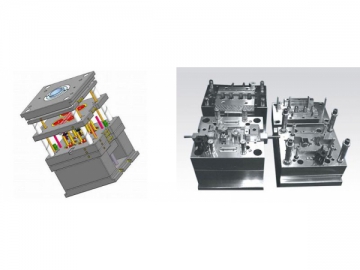

6. Accurate injection molding system

● Standard and modular design is adopted for the rubber injection molding unit

● It is applicable in the injection and molding process of rubbers with different hardness

● The accurate displacement sensing system, accompanied with the high-precision mechanical components, has effectively ensured the accuracy of rubber weighing and injection process

● The rubber weighing accuracy is guaranteed with an ultra-small back pressure

● The rubber residue and the loss of injection force is controlled to the min with a reasonable injection channel

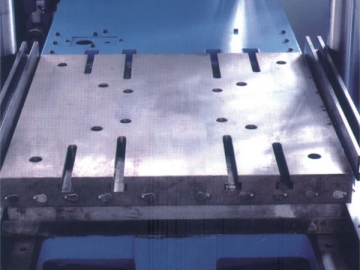

7. High-efficiency clamping unit

● Having undergone a finite element stress analysis and CAD 3D modeling process, the clamping unit of the injection molding equipment features a small deformation of no more than 0.10mm under certain load

● Supported by 2 assisted cylinders, the clamping operation can be done rapidly and efficiently. The clamping force works through a master cylinder directly, which has both ensured the operation consistency and saved the time. Efficient exhaust device, cooperated with elaborately-designed channel, provides a powerful guarantee for letting the harmful gas generated in the vulcanization process exhausted completely

● In the whole injection process, the modes of the plastic injection molding machine are adjusted gradually to ensure the safety and accuracy

8. Reliable packaging

We have asked professional packing companies to pack our plastic injection molding equipment with wooden boxes before delivery.

Customization Service

1. The plastic injection presses in Huatai are available in either single or double stations.

2. Machine color is customizable.

3. Customers have access to determine the specific spare parts or some parameters like platen dimension, clamping force, and injection volume, among which the clamping force ranges from 270KN to 2500KN.

4. Besides, we have collected 18 technicians who have accumulated over 20 years' working experience. The high proficiency allows them to make the exact plastic molding equipment clients want. Who clients need to offer are only the drawings and their detailed requirements.

| Model | SZL-300 | SZL-400 | SZL-500 | SZL-800 | SZL-1000 | SZL-1200 | SZL-1500 | SZL-2500 |

| Injection volume 50/100CC | 50/100CC | 50/100CC | 50/100CC | not applicable | not applicable | not applicable | not applicable | not applicable |

| Injection volume 200CC | not applicable | 200CC optional | 200CC optional | 200CC | 200CC | 200CC | 200CC | not applicable |

| Injection volume 300CC | not applicable | not applicable | not applicable | 300CC optional | 300CC optional | 300CC optional | 300CC optional | over 300CC |

| Clamping force (KN) | 300 | 400 | 500 | 800 | 1000 | 1200 | 1500 | 2500 |

| Clamping stroke (mm) | 490 | 500 | 500 | 500 | 450 | 450 | 600 | 400 |

| Max interval (mm) | 600 | 650 | 650 | 750 | 850 | 800 | 1000 | 1000 |

| Min mold thickness (mm) | 110 | 150 | 150 | 250 | 400 | 350 | 400 | 600 |

| Fast clamping | optional | optional | optional | Equipped | Equipped | Equipped | Equipped | Equipped |

| Platen size (mm) | 400 × 300 | 450 × 450 | 600 × 400 | 700 × 500 | 700 × 500 | 800 × 500 | 800 × 700 | 800 × 700 |

| Motor power (kw) | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 | 11 | 15 |

After Sales Service

1. Within the warranty period (1 year), clients can replace their broken parts for free.

2. For the consumable parts, we will send them to clients by express or together with the platic molding equipment.

3. All of our service personnel have accumulated over at least 10 years' working experience and they are proficient in the rubber injection molding field. Upon request, Huatai will assign some professionals to clients' production site to offer them technical instructions.