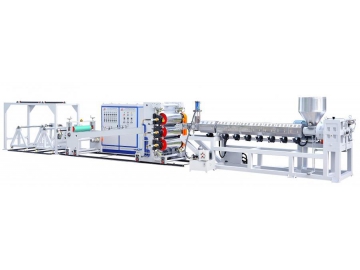

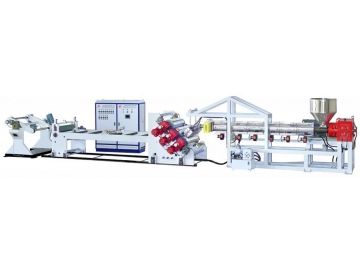

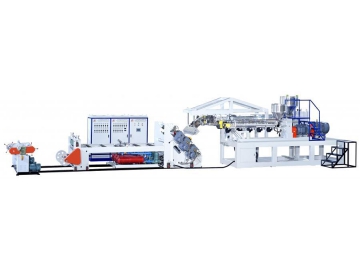

PP Foam Sheet Extrusion Line

Plastic Sheet Production Line, Extrusion Line for Plastic Sheet, PP Sheet Extruder

-

Production line for PP foam sheets

-

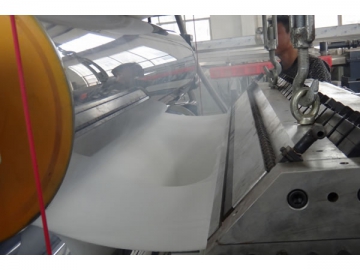

Dies for PP foam sheet and 3-roll calendering machine

-

Applications of PP foam sheet in fast food boxes

-

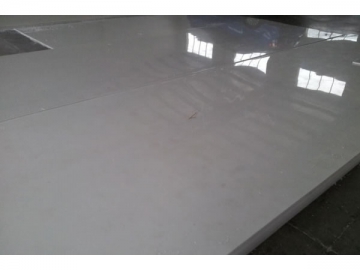

PP foam sheets

-

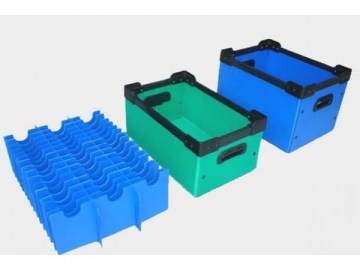

Crate for accessories

-

Packaging boxes

Polypropylene foam sheet is featured by little energy consumption, small density, and great performance in shock resistance, thermal insulation and cold resistance. It is widely applied in food packaging, interlining of bags and suitcases, pass box, automotive interior, building templates and so on, with a good market prospect. The patented Polypropylene microcellular foaming technique researched and developed by Zeqi is utilized in PP foam sheet production line, effectively limiting the density of PP sheet to 0.25-0.50g/cm3. Closed pore and microcellular foaming techniques are applied to ensure there is no residue left and the production process is fully environmentally friendly. So the line can be safely used for food packaging. Basing on clients' needs, this unit can be applied in producing single or multi-layer co-extrusion sheets of different-specifications. The whole unit is advanced in design with optimized and reasonable configuration, high-level automation, and easy and reliable operation.