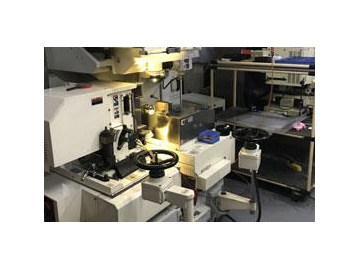

Hole Drilling EDM, Hole Electric Discharge Machining, EDM Drilling Machine

Request a Quote

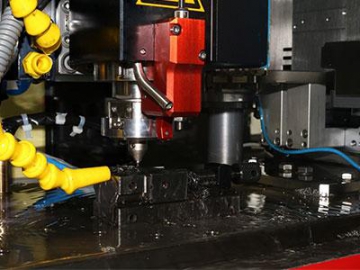

The hole drilling electric discharge machining (hole drilling EDM) machine is piece of auxiliary equipment for wire cut EDM units. It is mainly used for drilling holes into metal parts prior to wire cut EDM processing. The machine is capable of drilling into high hardness metals like tungsten steel and cemented carbide.

Parameters

| Model | Unit | JC-DM230D | JC-DM340D |

| Electrode diameter | mm | φ0.3-φ3.0 | φ0.3-φ3.0 |

| Spindle head travel | mm | 200 | 280 |

| Main servo travel | mm | 280 | 380 |

| Max. adjustment speed of spindle | mm/min | 200 | 800 |

| C axis speed | rpm | 20-120 | 0-500 adjustable |

| Worktable size | mm | 320*440 | 320*440 |

| X-Y | mm | 200*300 | 300*400 |

| Max. distance from guide apparatus to worktable | mm | 280 | 320 |

| Height from worktable surface to the ground | 30 | 40 | |

| Max. machining current | A | 30 | 40 |

| Max. input power | kw | 3 | 3.5 |

| Digital display mode | biaxial | biaxial | |

| Power input mode | V/HZ | 380/50 | 380/50 |

| Capacity of dielectric fluid tank | L | 25 | 25 |

| Filtration method of dielectric fluid | Small hole | Small hole | |

| Max. pressure of dielectric fluid | Mpa | 7 | 8 |

| Machine dimension(L*W*H) | mm | 800*800*1800 | 1000*1000*1900 |

| Machine weight | Kg | 700 | 800 |

Features

- Made of granite, the work table is not easily deformed.

- Equipped with digital display unit, the X-Y axis has the positioning function on the side.

- Drilling can pass through bevel or curved surface directly.

- The tap water is directly used as dielectric fluid.

- The operation panel is set in front of machine for the convenient of operators.

- Equipped with automated programming software, this EDM machine can be easily accessed by beginners.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos