Truck-Mounted Concrete Stationary Pump

Truck-Mounted Concrete Stationary Pump uses whole-hydraulicreversing open system, which has high reliability and little reversing impact. Thefeeding/ discharging capacity of pump can reach 140 m3 / h and achieve

Detailed Description of Truck-Mounted ConcreteStationary Pump

Concrete pump has many advantages, such as high reliability, economical, safety,wearable. The three main parts: chassis of concrete pump, boom system,

Chassis and Driving System (Truck-MountedConcrete Stationary Pump)

Adopted Benz chassis with comfortable cab and superior quality, turbo, and electronicfuel injection system, the diesel power capacity is strong and can provide withdurable driving support.

The motor speed is controlled by sensor monitor, which emits the corresponding command—whenthe motor speed decrease due to over loading, PLC emit a command to steppingmotor to increase throttle in increments, and if opposite, PLC

Boom System

1.

2. It has remote control and hand control two control methods. It also adopts thecomputer ration control technology which realizes the freely speed change, reliablyand steadily work and exactly fix location.

Hydraulic Pressure System (Truck-MountedConcrete Stationary Pump)

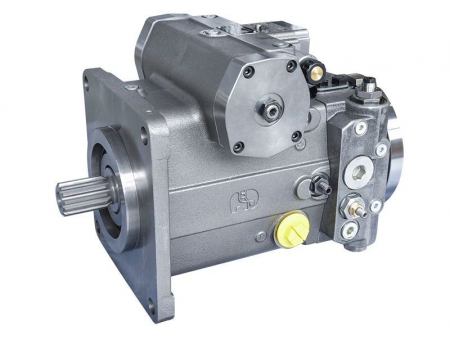

1. The hydraulic pressure system adopts the closed loop system, so the dischargeof the main oil pump becomes zero when reversed. There is no concussion whichrealizes the reliability of the hydraulic pressure system and boom system withthe most degree. The hydraulic pressure oil is very clean and the temperatureis low.

2. Main hydraulic components pumps and valves use German Rexroth,Stvff and American Vickers, Hawewhich make sure the pump conveying system's large discharging quantum, high efficiency,long life span, stable performance and the continuity of long time continuing-work.

3. The booms' oil pump uses an axial piston pump loading with sense variable, whichcan adjust the output according to the actual working situation and decreaseexhausting power and generating heat of the system.

4. With unique designed large stroke, the cylinders can meet concrete large dischargingquantum demand, the reversed times are reduced, and the life spans of thoseeasy abraded parts, like abrasion-resisting are prolonged.

5. The main oil pump adopts the electrical ration control and freely adjusts equipment,so the operator can adjust the discharge of the main oil pump through thebutton conveniently.

Pump Conveying System

1.

2. The “S” shaped tube is equipped with abrasion-resisting rings, so it can adjustthe clearance automatically to ensure high sealing performance.

3. The innovative design of “S” valve, abrasion-resisting board, mixing axes, sealinggroove and so on make it possible to convey 20, 000 stereconcrete without change the easy-abraded parts like conveying cylinder'

4. Adopt original oil tube from

Control System

1. The electronic system uses Germany-made Siemens PLC programming controller, andthe relay is from Japan-made Omron, which is strong in reliability and easy tooperate.

2. With the three operating sets, control board, cable remote control and radioremote control. It is convenient to operate.

3. Remote controller made in German HBC company accords with the

Technical Parameters of Truck-Mounted ConcreteStationary Pump

| Conveying | Theory. conveyer quantum | m3/ h | 145 |

| Theory. conveyer pressure | MPa | 7 | |

| Type of distributing valve | | “S”valve | |

| Hydraulic system pressure | MPa | 32 | |

| Conveyer diameter stroke | mm | Ф230×2100 | |

| Main oil pump output | ml/r | 125 125(double pump) | |

| Concrete falling degree | mm | 150~250 | |

| Direction exchange times | Times/min | 28 | |

| Diameter of pipeline | mm | 125 | |

| Hopper volume | m3 | 0.65 | |

| Capacity of water volume | m3 | 0.78 | |

| Capacity of oil volume | m3 | 0.9 | |

| Chassis | Chassis model | | Benz 4141 |

| Chassis driven type | | 8×4 | |

| Distance between wheel | mm | 6300 1350 | |

| Engine module | Benz | OM501LA.Ⅲ/17 | |

| Engine power and speed | kW/r | 300/1800 | |

| Torque and RPM | Nm/rpm | 2000/1080 | |

| Engine emission standard | | Euro Ⅲ | |

| Max. running speed | km/h | 85 | |

| Min. turning radius | mm | 12.95 | |

| Total weight | kg | 40000 | |

| Dimension(L×W×H) | mm | 12440×2490×3980 | |

| Max. climbing degree | | 53.1% | |

| boom | Perpendicular height | m | 46.2 |

| Horizontal radius | m | 42.16 | |

| Depth reach | m | 32.52 | |

| Boom proportional distributing valve | | HAWE | |

| Boom control system | | Manual, wire and wireless remote control | |

| Boom folding system | | upper fulcrum “R Z” mode | |

| Slewing range | degree | 365 º | |

| Arm number | | 5 | |

| Rotation angle of boom joints | degree | 94 º/180 º/180 º/180 º/265 º | |

| Height of adding material | mm | ≤1500 |

Note: Materials andspecifications are subject to change without notice.