DXD-80A Premade Bag Filling Sealing Machine

Application

DXD-80A premade bag filling sealing machine is a set of packaging machine, which uses the premade bags and heat sealing bags. The premade bags consist of standing bags, zip bags, spout bags, flat bags and so on. Besides, the machine is designed with 8 stations and filling range of 10~2000g. The model of packaging machine is widely applied to the packaging of snacks, candies, chocolates, nuts, peanut, pet food, powder, sugar, soft drinks and so on.

- Cashew packaging sample

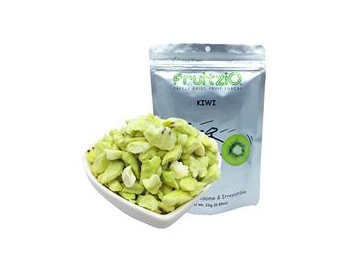

Dried fruit packaging sample

Dried fruit packaging sample Nuts packaging sample

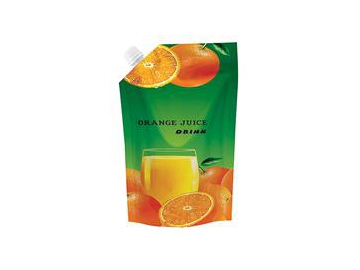

Nuts packaging sample Beverages packaging sample

Beverages packaging sample

| Model No. | |

| Station No. | 8 |

| Packaging Materials | Laminated film, PE, PP etc. |

| Bag Type | Zip standing bag, Standing bag, standing spout bag, flat bag(three sides sealed, four sides sealed), carrier bag, zip bag |

| Bag-making Size | W: 80-250 mm, L: 100-400 mm. |

| Filling Range | 10-2000g |

| Weight error | ±0.5-1.5g |

| Packaging Speed |

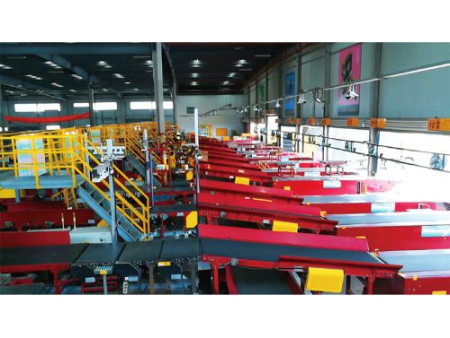

1. Z Shape Bucket Elevator

The materials are commonly transported from ground hoppers to multihead weigher with help of bucket elevator. This type of feeding machine has a higher efficiency working together with multihead weigher.

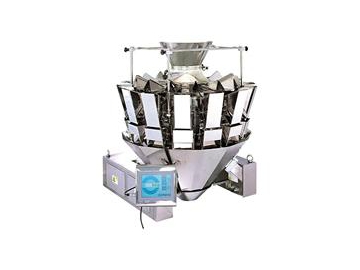

2. Multiheads Weigher

Multihead weigher is a kind of automated weighing system, which can be customized as 10 heads weigher, 14 heads weigher and 20 heads weigher. The weigher is equipped with a touch screen controller. When the required weight changes, it is very convenient to resetting target weight on the touch screen without replacement of components. Besides, this weighing system is very precise and weight error of each bag is less than 0.5%.

3. Premade Bag Packaging Machine

After the weighing procedure is finished, pre-made bag packaging machine will complete the steps of conveying pre-made bags, data printing, opening pre-made bags, first filling, second filling, first heat sealing, second heat sealing, finishing packaging and conveying to designated area.

1. The packaging unit is equipped with multihead weighing system and ensures the packaging weight error within 0.5g. Besides, this weighing system has a touch screen control petal, which is convenient to change target weight without any replacement of components.

2. Z shape bucket elevator's feeding bucket is on the ground for the convenience of users. Besides, the feeding machine has a high efficiency working with weighing system.

3. Panasonic PLC control system control the packaging process intelligently in the packaging unit.

4. The premade bag fill seal machine installs Weinview touch screen control petal, which is convenient for setting running parameters and easy to handle by users.

5. The packaging equipment is equipped with testing system. When the bag cannot open, the filling and sealing procedure will not start, which can avoid the waste of materials. Besides, the unopen bags can be recycled.

6. We have installed constant temperature heating system ensuring stable temperature in the packaging process and the beauty of sealing.

7. When the bag size changes, do not need to replace components and just reset the parameters in the machine.

8. Our machine is equipped with a printer with the function of printing production date and batch numbers and so on.

9. The maintenance cost is very low because it has few damageable assemblies.

10. The components contacted with product materials are all made of stainless steel meeting the requirements of food manufacture.

11. This premade bag filling sealing can match with a screw weighing system to transformed into the packaging machine of powder materials.