YHZS Mobile Concrete Batching Plant

Request a Quote

| Type | YHZS25 | YHZS50 | |

| Production (m3/h) | 25 | 50 | |

| Mixer | Type | JS500 | JS1000 |

| Power (KW) | 22 | 2X18.5 | |

| Discharging Capacity (m3) | 0.5 | 1 | |

| Aggregate Bin (m3) | 2X13 | 2X13 | |

| Weighing Accuracy | Aggregate (KG) | ±2% | ±2% |

| Cement (KG) | ±1% | ±1% | |

| Total Power (KW) | 52 | 68 | |

| Gross Weight (KG) | 23000 | 25000 | |

| Movement Speed (KM/H) | 15 | 15 | |

| Turning Semi-Diameter (M) | 10 | 10 | |

Features of Modular Concrete Batching Plant

- Stability and Durability: adapt and apply the most advanced technologies around the world;

- Reliability: 30 years of experiences in manufacturing concrete mixing plants;

- Stationary modular structure, fast and easy installation;

- High-quality mixer, excellent mixing performance with high efficiency and high productivity;

- Double computers with double controls, easy operation;

- Excellent environmental protection, dust collection system and anti-noise design.

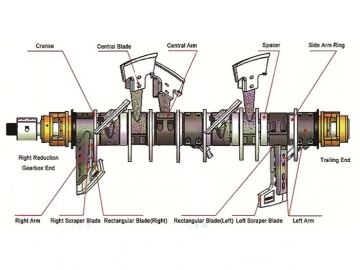

- Horizontal twin-shaft compulsory mixer has the strong mixing ability with uniform mixing and high production output. The admixtures are widely mixed by the shafts, and reach the best proportional ratio of uniform;

- The mixing shafts adapt anti-binding technology to prevent the cement from binding on the shafts. Shaft seals use multi-sealed structures to effectively prevent the slurry leakage. Shaft bearings are outboard designed, and are replaceable;

- Mixing paddles, arms and blades are made of special high chromium and high manganese alloy materials. The wear resistance of the mixing paddles saves time and cost to replace, and at the same time, improves the machine's durability and reliability;

- The greasing system, which is controlled by central control system, lubricates the greasing points at the fixed position, fixed time and fixed quantity. The reliable and effective greasing system reduces the oil consumption, and has easy daily maintenance;

- Decelerating system uses high-speed, synchronized, and closed planetary decelerators. Compact structure, high efficient transmission, and easy maintenance improve the machine's durability and reliability greatly;

- The opening of discharge gate can be adjusted by hydraulic system as per specific requirements. Emergency discharging function: when the machine accidentally stops, it is able to manually open the discharging gate and discharge the remaining admixtures.

- The batcher, with 3-5 aggregate hoppers, can be assembled as per individual requirements. There are independent weighing hoppers and belt conveyor under the aggregate hoppers that could be designed as steel structure type, underground and half-underground types. The aggregates can be fed into the aggregate hoppers by loader or belt conveyor.

- The hopper discharging gates and discharging speed are controlled by computer via cylinder. After aggregates scaling, the aggregates will be conveyed into the transitional hopper.

- Each and every aggregate is weighed individually or accumulatively, and the weighing accuracy is guaranteed. The accuracy of aggregates proportional ratio is realized through computer control system, which automatically re-feeds the aggregates if there is shortage of weight, warns if there is overweight.

- The aggregates are conveyed into the hopper by the inclined angle ≤20°belt conveyor, with the gravity tension device or by the trough belt conveyor in order to save space.

- The closed aggregates belt conveyors are designed to avoid aggregates overflowing and noise pollution.

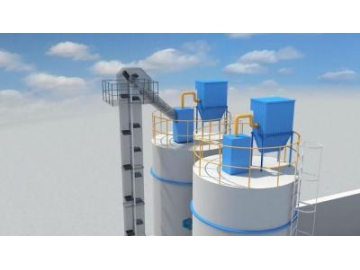

- Modern modular structure designed mixing tower. All parts of mixing tower are connected by bolts and nuts structure. It is easy and fast to install and dis-install the whole plant, and it saves the time and cost to install and test the plant greatly;

- The tower, with compact structure, is made of external closed and colorful shaped steel plates, which are anti-noise, anti-dust, and heat preserved;

- Has maintenance and repair platforms and stairs with comfortable space;

- Washing system has high-pressure pumps, with automatic control and manual control;

- Closed structure design, closed aggregates conveyor, and external 360°lighting allow all-weather operation;

- The mixing tower can be designed as "—", "L", and "T" shapes. Extensional designs are feasible as per specific requirements.

- Water weighing and supplying are controlled by precise weighing sensors, pneumatic butterfly valves and spherical valves, which guarantee the weighing accuracy;

- The pressurized water by water pump can spray out and mix with the materials rapidly in the mixer, collect the dusts and wash the mixer thoroughly at the same time;

- The liquid admixture weighing system, with weighing sensor, has unique leakage-proof device. The liquid admixtures, mixed with water, spray out in the mixer.

- Cement and coal ash are conveyed by screw conveyor, and are weighed by high-precision sensors and computer control;

- The weighing hopper will feed the cement and coal ash to the mixer by opening the pneumatic butterfly valve, when the weight reaches the set perimeter and the computer will send an order to stop the screw conveyor;

- Different weighing formulas can be designed as per different quality of materials, from storing, conveying, to weighing.

- The control system of double computers with double controls consists of two industrial computers, one is production control computer and the other is production management computer. The control system has the following functions:

A.Automatic and manual control, easy operation;

B.Dynamic display of the production process, and monitoring in real time;

C.Saving of the data of production perimeters in the computer, printing of the daily, monthly, and yearly statistic reports of production;

D.Weighing accuracy: automatic re-feeding if there is shortage of weight, warning if there is overweight;

E.The operators, with the assistance of safety monitoring system, will know and monitor the running situations of the mixing plant in the control room; - The management computer is a backup computer for the whole electric control system. When the control computer is out of order, the management computer can be changed into the control computer to control production.

- Long-distance trouble shooting by internet and teleservice, which greatly improves the user's ability to trouble shoot the system.

- The control room, which is made of colorful shaped steel plates, is capacious, anti-noise and heat insulated. It guarantees the working temperature of the electrical components, also improves the working comfortability.

- All the powder materials are conveyed under closed conditions from the conveying, dosing, batching, feeding to mixing;

- The main mixer, cement weighing hopper and coal ash weighing hopper are all connected by dust suction pipes and compulsory dust extraction filter;

- Atomized spraying of water uniformly mixes the water with cement, and at the same time, collects the dust;

- Labyrinth dust-resistant plates and compulsory dust extraction filters at the aggregates discharging gate minimize the dust emission and pollution;

- The fully closed mixing tower and closed belt conveyor greatly reduce the dust and noise pollution.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos