Water Jet Cutting Machine

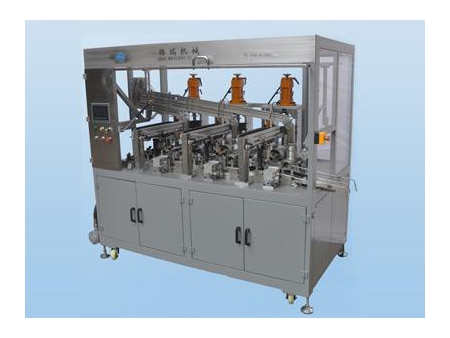

Providing 50 years of experience in manufacturing machine tools, we use advanced technology to provide equipment with the most reliable performance. The water jet cutting machine is controlled by CNC system and has no limit on cutting direction, enabling it to produce various open or closed plane figures out of the material. This avoids a rough edge finish to achieve excellent edge quality. In addition, the water jet cutting machine improves the operator's work environment as no toxic gas is produced.

The water jet cutting machine offers many time and cost saving features. Because the machine exerts little applied force in the horizontal and longitudinal direction, the cutting accuracy makes time setting easy and the use of jigs unnecessary. Since the water jet cutting machine can accomplish both boring and cutting, this saves on production cost. The machine will not produce heat-affected zone, deformation or tiny breaks in the material, so there is no need for secondary processing.

The water jet cutting machine minimizes material waste by creating very narrow kerfs. Due to the use of quality high pressure generating elements and economical wear parts, the machine is easy to maintain greatly reducing time and costs incurred by maintenance. Last but not the least, the water jet cutting machine can be adjusted to meet the requirement of different designs and materials, shortening the production period to bring you more business opportunities.

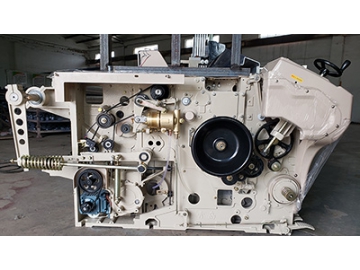

The ultra-high pressure water jet cutter is commonly used in cutting automobile interior and exterior trimming parts, including carpet, roof panel, bumpers, door panel, instrument board, seats, trunk hood, mats, damping devices, and other composite parts. With the use of a multi axis robot arm, the water jet cutting machine is quite flexible and saves on cost. The multi axis robot arm cutting system can be easily integrated into the manufacture process. All in all, the system provides a cleaner, safer and more accurate solution to promote productivity and minimize the effect of heat.

The water jet cutting machine also has a wide range of application in exterior and interior decoration industry. In particular, the use of the water jet cutting machine has greatly enriched available patterns of ceramic parquet to satisfy the needs of consumers. The water jet cutting machine is capable of cutting various complex or simple geometric plane figures. Using automatic computer control, the water jet cutter can cut out figures exactly the same as designed on the computer. Since mechanic stress and the effect of heat are avoided, the water jet cutter does not change the original shape and hardness of materials such as tiles, stone and glass. In this way, every tiny detail of the plane figure can be reproduced on the material.

To meet diverse market demands, the water jet machine also provides a convenient and effective solution for the glass industry. The machine is capable of cutting any figure you may need, while also excelling at shaping and boring. The water jet cutting machine can work out diverse, precise and good looking figures with smooth and frosted cuts.

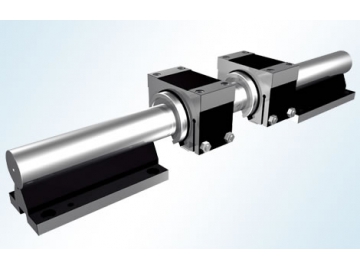

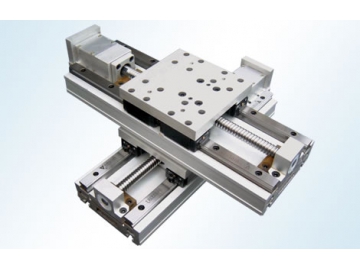

As a professional water jet cutting machine manufacturer based in China, YiGong offers an extensive line of products that includes linear motion spline, linear guide, precision ball screw, linear motion bushing, and much more.