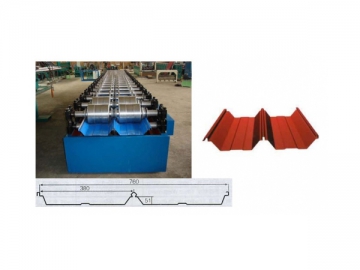

760 Standing Seam Panel Roll Forming Machine

Advantages of the 760 Standing Seam Panel Roll Forming Machine

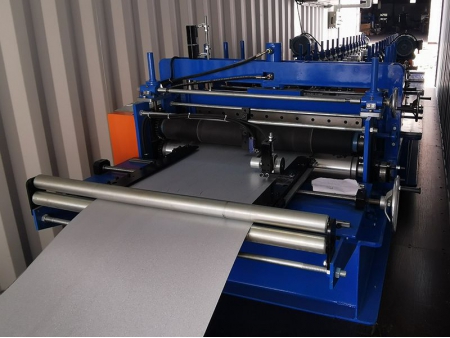

The 760 standing seam panel roll forming machine is upgraded based on traditional roofing sheet machinery. It mainly consists of an uncoiler, an uncoiler base, a feedstock guiding table, a roll forming system, a cutting device, a hydraulic power unit and a control panel etc. Thisheavy-duty standing seam machine is specially built for the upscale market. The DVP14ES computer control system paired with a display screen makes this rollformer easy to use.

Unlike conventional similar products, this concealed roof panel forming machine provides a quality solution to roof leak problem. It allows metal roofing sheets to be interlocked rather than to be bolted, thus making roofs extremely waterproof. Our equipment is easy to operate, maintain and debug. It also enables easy replacement of all roll forming dies.

Main Specifications of the 760 Standing Seam Panel Roll Forming Machine

| Overall Dimension | 10.6m *1.5m*1.5m |

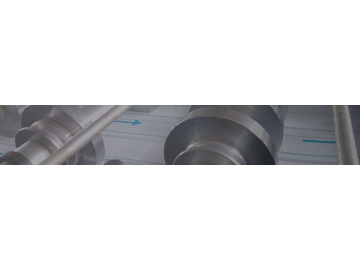

| Forming Method | Roll forming (pre-pressing) |

| Roll-Forming Shaft | 22 rows |

| Width of Feed Material | 1000mm |

| Thickness of Iron Plate | 10mm |

| Thickness of Roll-formed Sheet | <0.8mm |

| Shaft Diameter | Φ70mm |

| Motor Power | 5.5KW |

| Working Speed | 12m /min. |

| Machine Weight | Approximately 4T |

| Pump Motor | 3KW |

| Frame Material | 500H steel |

| Cutter Material | Cr12 |

| Drive Method | 1.31inch sprocket and chain |

| Electrical Control System | DELTA PLC |

| Steel Plate Model | 51-380-760 |

| Effective Width | 760mm |

| Feeding Width | 1000mm |

| Sheet Thickness | 0.6mm , 0.8mm, 1.0mm |

| Moment of Inertia of the Cross Section | 32.27cm4/m, 49.69cm4/m, 62.11cm4/m |

| Moment of Resistance of the Cross Section | 12.29cm3/m, 16.39cm3/m, 20.48cm3/m |

| Uses | Concealed roof panel or wall panel |