Aluminum Connection Steel Partition Cleanroom Wall Panel System

Aluminum Connection Steel Partition Cleanroom Wall Panel System

MAX-CR-A 50 aluminum connection steel partition cleanroom wall panel system which mainly adopts the baking finish steel plate of low dust content, is well applied to the electronic or pharmaceutical clean room. Particularly, it is well applied in all the pharmaceutical clean rooms of ISO standard from CLASS 1 to CLASS 9. In addition, our product is in full compliance with the FDA, EV and the requirements of the new edition GMP in

Since it was launched into the market in 2001, our economical MAX-CR-A 50 aluminum connection steel partition cleanroom wall panel system not only has a good application in

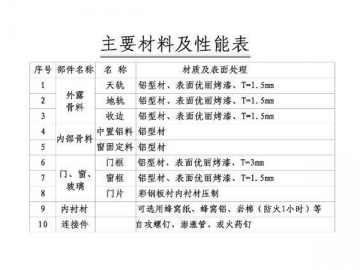

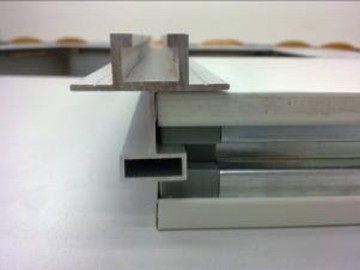

Materials and Performance Table

No. | The Name of Parts | Name | Material & Surface Treatment |

1 | Exposed Accessory Material | Ceiling Track | Aluminum profile, qualified baking varnish, T=1.5mm |

2 | Floor Track | Aluminum profile, qualified baking varnish, T=1.5mm | |

3 | Edge | Aluminum profile, qualified baking varnish, T=1.5mm | |

4 | Internal Accessory Material | Built-in aluminum material | Aluminum profile |

5 | Materials used for window fastening | Aluminum profile | |

6 | Door, window, glass | Door frame | Aluminum profile, qualified baking varnish, T=3mm |

7 | Window frame | Aluminum profile, qualified baking varnish , T=1.5mm | |

8 | Door | The pressing between the color plate and lining material | |

9 | Lining material | Paper honeycomb, aluminum honeycomb, rock wool (one hour fire protection), etc. | |

10 | Fastenings | Self tapping screw, expansion pipe, gunpowder nails |

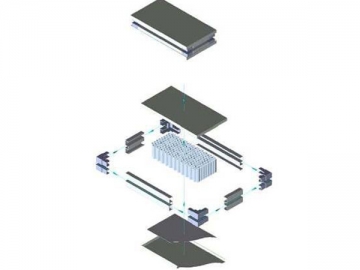

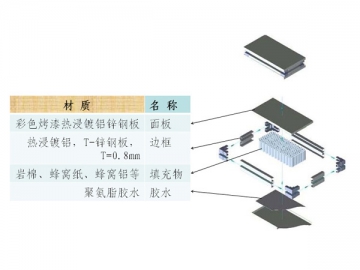

Panel Structure Illustration

Material | Name |

Color baking varnish hot-dip galvalume steel plate | Panel |

Hot dip aluminum, T-galvanized steel sheet, T=0.8mm | Frame |

Rock wool, paper honeycomb, aluminum honeycomb, etc. | Filling materials |

Polyurethane adhesive | Adhesive |

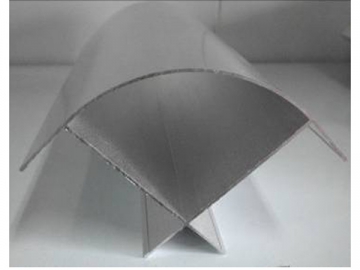

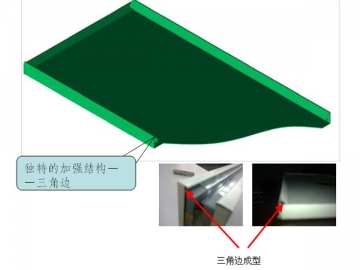

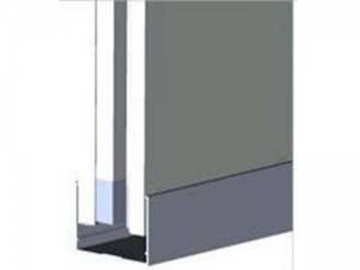

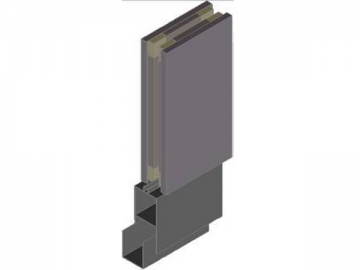

Plate Structure Features

The plate manufactured with the customized special-purpose machinery has high intensity for its pioneered panel reinforced structure. It is suitable for MAX-CCR-A 50 series wallboard and MAX-CR-B 100 series partition plate.

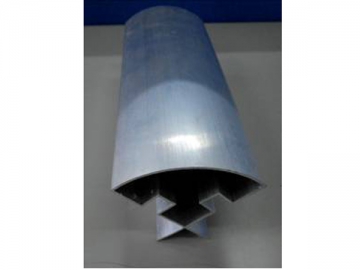

As compared to the one with the right-angle side molding, our MAX aluminum partition wall panel with triangle side molding is higher in intensity and strongly resists bending and deformation. In addition, our panel can be quickly assembled. Its width modulus could be

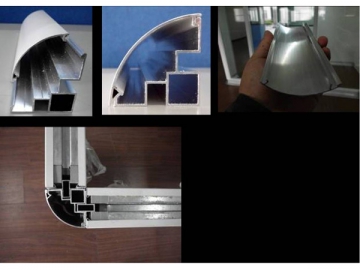

独特的加强结构Unique Reinforced Structure——三角边Triangle

三角边成型Triangle Side Molding

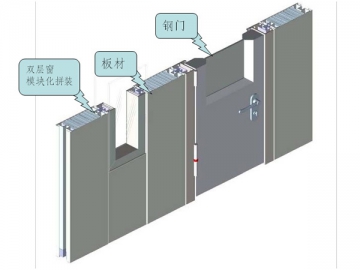

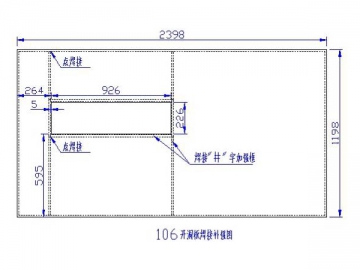

双层窗模块化拼装Modular Assembly of the Double Windows

板材Panel

钢门Steel Door

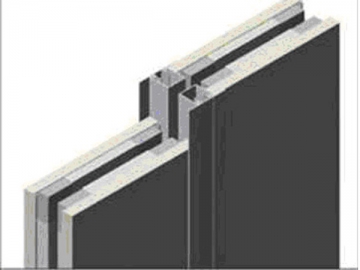

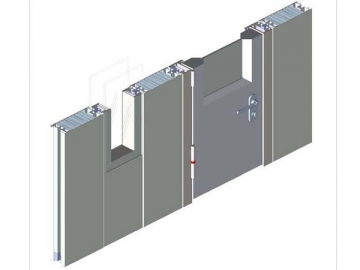

Modular Combination

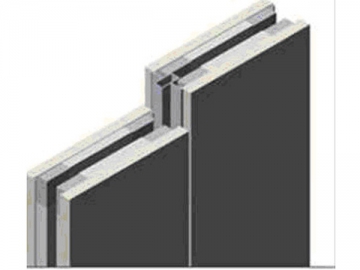

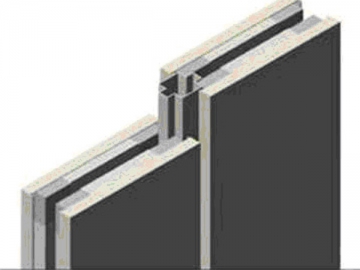

MODEL | MAX-CR-A1 | MAX-CR-A2 | MAX-CR-A3 | |

Connection Rendering |

|

|

| |

General Physical Performance | Wall Thickness | 50mm, 100mm | 50mm , 100mm | 50mm , 100mm |

Conventional Width | 900mm,1160mm,1200mm | 900mm , 1160mm, 1200mm | 900mm , 1160mm,1200mm | |

Max. Length | 6000mm | 6000mm | 6000mm | |

Main Material | Panel Material | Painted galvanized steel sheet | Painted galvanized steel sheet | Painted galvanized steel sheet |

Filling Material | Paper honeycomb, aluminum honeycomb, rock wool, magnesium oxide, etc. | Paper honeycomb, aluminum honeycomb, rock wool, magnesium oxide, etc. | Paper honeycomb, aluminum honeycomb, rock wool, magnesium oxide etc. | |

Connection | Aluminum alloy extrusion, 2mm gap | Aluminum alloy extrusion, 18mm gap | Aluminum alloy extrusion, 10mm gap | |

Fire Resistance | 60min fireproofing | 24min fireproofing | 24min fireproofing | |

Applicable Place | Electronic clean room, pharmaceutical clean room, operating room, office partition, etc. | Electronic clean room, pharmaceutical clean room | Kinds of office partitions and functionality decorations | |

Diversified Panel Points

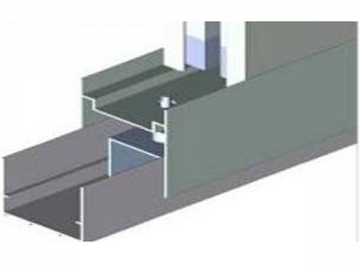

The Panel Point between the Wall and Floor

The third adjustable aluminum alloy floor rail is ideal for use in the bio-pharmaceutical plant, for heights up to

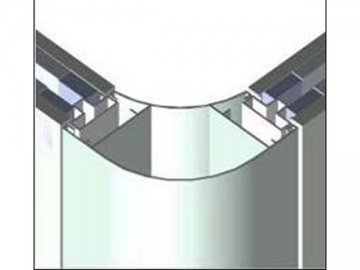

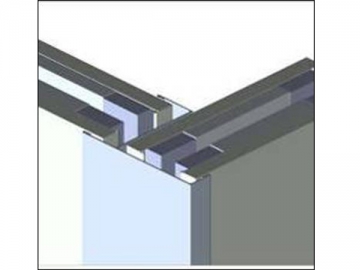

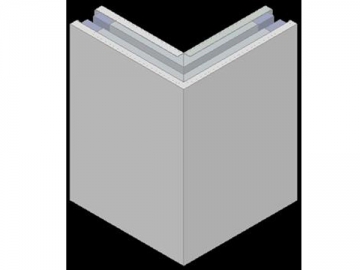

Corner Panel Point

Corner One

Corner Two

Corner Three

Corner Four

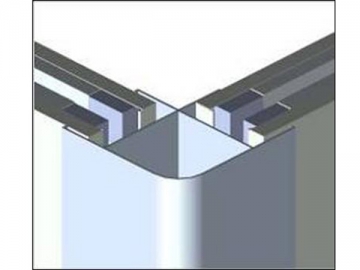

The Openable Bead Angle

The openable bead angle features smooth transition when being connected to the wallboard. It requires low cost and can be easily cleaned. The cover board should be installed when there are a few construction workers or the protection for the finished products is not good enough.

Corner Five

The followings are MAX standard corners like Corner Three, Corner Four and Corner Five, all of which are strongly recommended for the bio-pharmaceutical factory. Corner Three is most expensive and the Corner Five is the cheapest. Both Corner Three and Corner Five are made of aluminum alloy, having no fireproof limitation. Corner Four made of steel plate comes with the highest fireproof limitation and the best air tightness performance. Moreover, as the MAX patented product, Corner Five features outstanding maintainability.

从可维护的角度考虑,转角五最优秀,这只转角也是MAX的专利产品:安装时先将内衬装好,待工程基本结束,无交叉作业时,再安装圆弧扣盖,最大限度的避免了圆弧转角位置的成品损坏

Corner Five is the MAX patented product which is extremely outstanding in maintainability. Prior to the installation, you have to install the lining material. After the program is finished, then you can install the circular cover, thus greatly avoiding the damage of the finished circular corner.

The Small Plug-in Aluminum Alloy Corner

Plug-in small aluminum alloy corner which requires low cost is extensively applied to both electronic and pharmaceutical plant.

The Internal and External Angle System with the Bolt

Ceiling panel and metal wall panel, both of which could be