How It Works

Bespoke bags produced by China Blooming are tailored according to your desired material, color, size, and other specifications. Applying your creativity with that of our designers along with their experience, we can create wonderful products together that will add value while looking and performing great.

China Blooming, headquartered in Guangdong province, widely referred to as the “world’s factory”, has access to a complete manufacturing supply chain. Our factory is situated near two major fabric markets, allowing us to offer a wide variety of affordable fabrics for you to choose from.

We employ an experienced team to help you step by step from design to fabric selection based on all your needs. Therefore, we can quickly and accurately complete prototype samples within one or two weeks. This helps to avoid unnecessary costs caused by repeated modifications.

We adopt a standardized flow production mode as we are equipped with 12 production lines and more than 300 experienced well-trained operators. Thanks to a variety of semi-automated processing equipment, every process from raw materials to finished products can be carried out successfully.

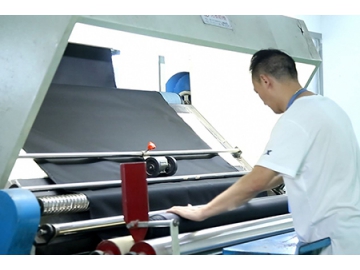

- Raw material inspection

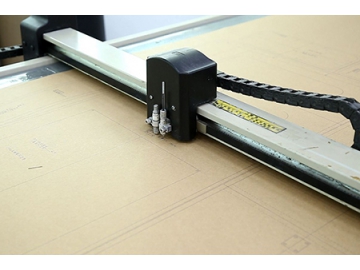

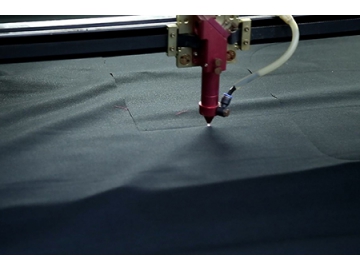

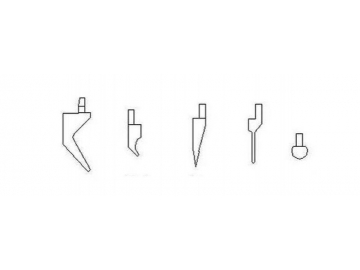

- Precise cutting

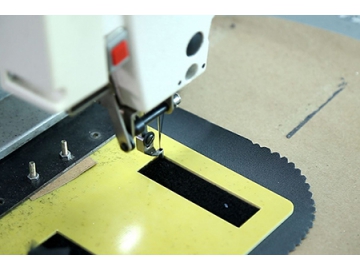

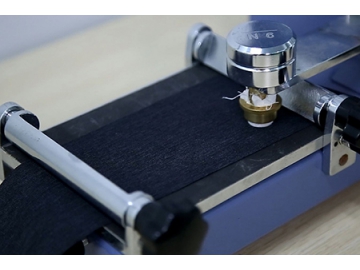

- Mechanical sewing

- When printed or embroidered fabric pieces are required, every single piece is strictly inspected to prevent unqualified semi-finished products from passing through to subsequent manufacturing processes. As a result, we can avoid unnecessary reworking that causes increased costs.

- Zipper testing is carried out by pulling the slider back and forth 30 times during the zipper assembling process.

- In the process of bag hemming, we use double-fold hems instead of single-fold hems, which makes lining fabric free from broken or skipped stitches.

- Any parts subjected to force are reinforced for greater durability.

- One of the most critical factors in producing high quality bag products is fabric selection. The raw materials are thoroughly inspected to ensure that the color and yarn density of the fabric meet the production requirements of customers.

Needle detector

Needle detector Salt mist testing

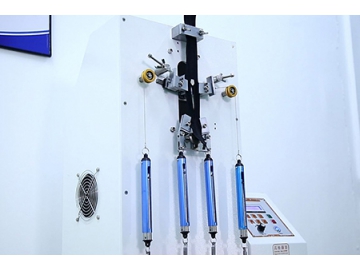

Salt mist testing Pull force testing

Pull force testing Colorfastness testing

Colorfastness testing Zipper testing

Zipper testing Load bearing test of shoulder straps

Load bearing test of shoulder straps