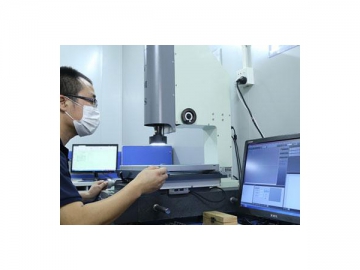

Quality Control

Request a Quote

To ensure the quality of products, Dasite strictly controls the quality of every procedure.

The testing process includes: sampling and testing of original material, sampling and testing during the producing process and changing material trays.

Testing procedure- Visual detection

- Property test

- Hardness test

- Quantity test

(1) The products are packaged with woven bags.Every bag 25±0.2Kg

(2) Weight machine with a precision of 0.1kg used for weighting

| Number | Type | Device name | Quantity | Test content |

| 1 | LHJ-02 | XLB-D Flat vulcanizing machine | 2 | Compressing samples |

| 2 | CPJ-01 | CT-7016 Slicing machine | 1 | Cutting samples |

| 3 | LLJ-01 | CMT6104 Universal testing machine | 1 | Breaking strength/elongation |

| 4 | SFJ-01 | GT-PD600 Infrared moisture meter | 1 | Water content |

| 5 | YDJ-01 | LX-A Rubber hardness tester | 1 | Hardness |

| 6 | GZJ-01 | ZC36 High-resistance meter | 1 | Volume resistivity |

| 7 | SLY-01 | UXRZ400 Melt flow index tester | 1 | Melt index |

| 8 | TP-01 | TG328A Densitometer | 1 | Density |

| 9 | SRSYT-01 | ZNY-9 Breakdown voltage tester | 1 | Disruptive strength |

| 10 | SYX-01 | SDD-01 Low-temperature testing chamber | 1 | Property of low temperature |

| 11 | LHX-01 | 401B Air ventilation aging test chamber | 1 | Property of aging |

| 12 | NHSYJ-01 | HY-867 Flame resistance tester | 1 | Flame retardant property |

- We will sample the first product of every batch and test its tensile property and flow rate. Other test items need to be tested according to the requirement.

- When the production continues, we will test the product's tensile property and flow rate every morning.

- When testing the properties, we will regard the first sample as our standard, and we will draw twofold samples randomly in this batch.

- Only if one index in the test is not corresponding to the standard, we will sample again and reexamine this item. If the result is still not up to par, we will judge this batch as unqualified products.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos