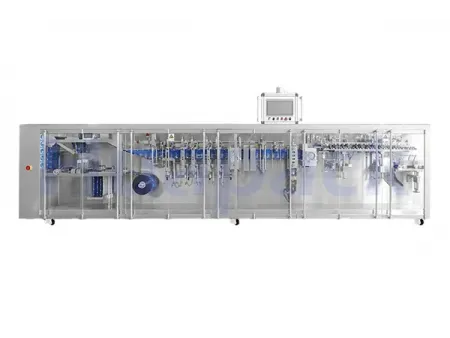

Rollstock Shaped Pouch Packaging Machine, 4-Nozzle Filling

The rollstock shaped pouch packaging machine is designed for high-output production using roll film to form shaped pouches directly on the line. With a production speed of up to 180 pouches per minute, it is suited for large-scale manufacturing environments, particularly in the personal care and daily chemical industries where efficiency and consistency are critical. It combines a high level of automation with precise motion and sealing control. Even at high speeds, pouch filling remains stable, sealing quality is consistent, and finished pouches maintain a clean, well-defined shape. The system is designed to support continuous operation while protecting product integrity and packaging appearance.

| Model | 400SQY | |

| Pouch parameters | Min. pouch size (W × H) | 60 mm ×130mm |

| Max. pouch size (W × H) | 90 mm ×200mm | |

| Max. filling volume (stand-up pouch) | 100ml | |

| Packaging speed | ≤200 packs/min | |

| Equipment specifications | Dimensions (L × W × H) | 3475mm×1215mm×1600mm |

| Net weight | 1800kg | |

| Operating conditions | Operating temperature | -10℃ to +55℃ |

| Relative humidity (non-condensing) | ≤ 85% | |

| Power supply | AC380V, 50Hz | |

| Operating air pressure | 0.6Mpa | |

| Air consumption | 400L/min | |

| Motor power | 4.5Kw | |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

Guizhou Biotechnology is a health supplement manufacturer. In 2024, they purchased this rollstock shaped pouch packaging machine from us and has been our long-term customer, having introduced multiple packaging machine models over time for different production needs.