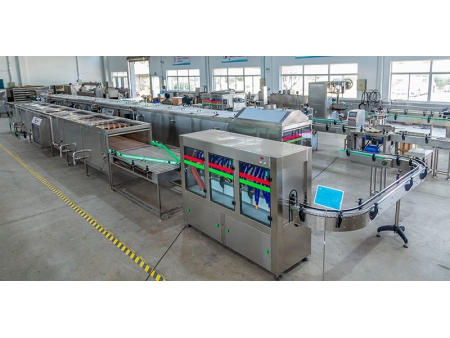

Premade Pouch Packaging Machines

Sauces typically have certain weight and flow characteristics, requiring packaging materials with enough strength and flexibility to withstand the pressure from the sauce, preventing the packaging from cracking or deforming. A good seal effectively prevents external air and moisture from entering, avoiding oxidation, spoilage, and microbial growth, thus extending the product’s shelf life. Our packaging machines ensure tight and secure seals.

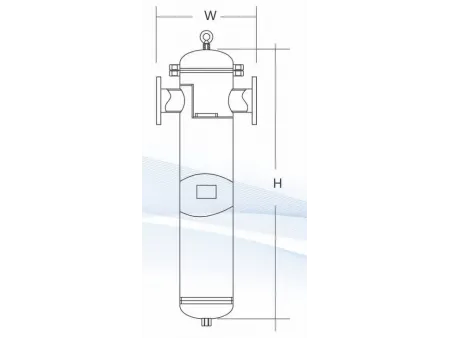

Some sauces contain particles, so our feeding system is designed to handle particle-containing sauces, and it features a stirring function. An optional heating and insulation feature is also available.

Different sauce products may require various packaging specifications and formats. Our packaging machines offer compatibility and flexibility, allowing for quick adjustments to meet different production needs, reducing the time spent on equipment changes and adjustments.