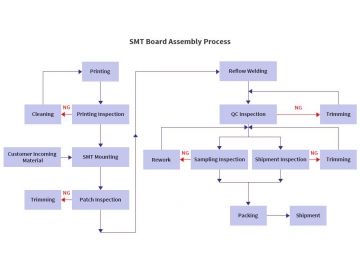

SMT Board Assembly Process

Cleaning - customer incoming material - trimming - printing - printing inspection -SMT mounting - patch inspection - reflow welding -QC inspection - sampling inspection - rework - shipment inspection – packing-repair -shipment

Printing: its role is to print the solder paste or patch glue leakage on the pad of PCB, preparing for welding components. The equipment used is the solder paste printing machine.

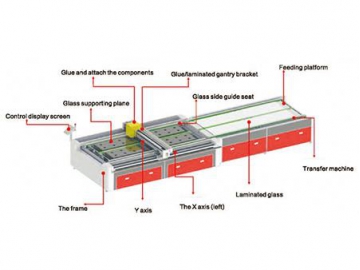

Glue dispensing: most of the circuit board used now is double-sided, in order to prevent the input surface of components falling off because of the solder paste melting again when second return, so in the input surface adding glue dispensing machine, it is drop the glue to the fixed position of PCB, its main role is to fix the components to the PCB board. The equipment used is a high efficiency glue dispensing machine, which is located at the front end of SMT production line or behind the detection equipment.

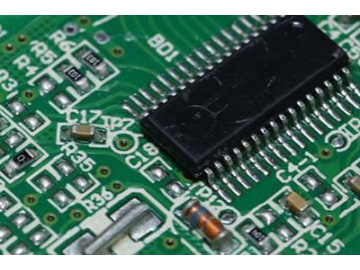

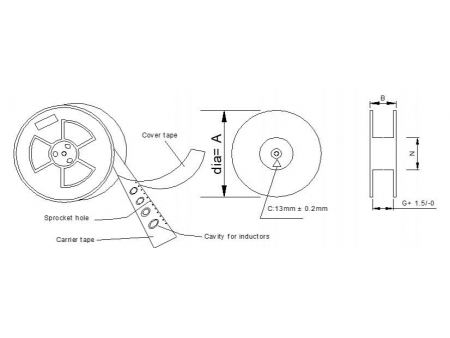

Mounting: its function is to install the surface mounting components accurately to the fixed position of PCB. The equipment used is the chip mounter.

Curing: its function is to melt the adhesive so that the surface mounting components are firmly bonded to the PCB board. The equipment used is the curing furnace.

Reflow soldering: its role is to melt solder paste, so that the surface assembly components and PCB board can be firmly bonded together. The equipment used is the reflow soldering furnace.

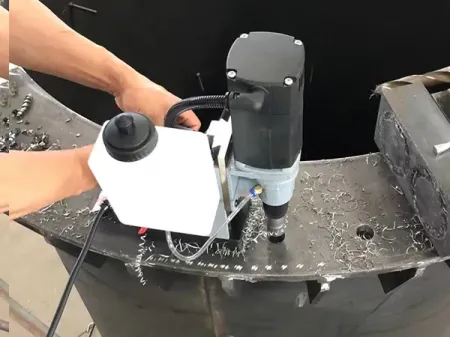

Cleaning: its function is to remove the harmful welding residues, such as flux, on the assembled PCB board. The equipment used is the cleaning machine.

Detection: its function is to detect the welding quality and assembly quality of the assembled PCB board. The equipment used include magnifying glass, microscope, on-line testing instrument (ICT), flying needle tester, automatic optical inspection (AOI), X-RAY detection system, function tester and so on.