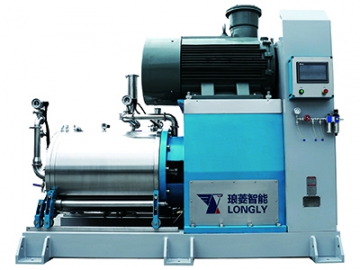

Disc Agitator Bead Mill with Static Sieve, RTSM-AJ Series

Request a Quote

RTSM-AJ series disc agitator bead mill with static sieve is designed for industrial mass productions of water-based, oil-based materials and other materials with low viscosity. With centrifugal force driven product outlet filtered by static sieve, larger outlet rate is allowed, and larger production capacity can thus be achieved. Milling processes including single-pass and re-circulation milling by a single mill, and co-operated milling by two mills are available, optimized disc agitator and product outlet structures provides better grain fineness and evenness. The best particle fineness and evenness can be D90<1μm.

Features

- Stable mechanical seal: double mechanical seal provides great sealing performance and stability; you can choose proper coolant according to processed material, with our sealing design you don’t have to worry about material pollution from coolant or other things from outside.

- Efficient cooling system: cooling structure of the grinding unit is precisely designed to make sure that every corner is fully cooled down during operation; transmission belt pulley is made of high-thermal-conductivity material, grinding product is thus free from the influence of external heat; multiple cooling steps for balance tank, end cover, etc. to ensure stability.

- User friendly: Root’s exclusive drive system adjustment design grants great convenience for service and maintenance; fast & convenient pipeline connection/disconnection; defroster is equipped to ensure stable operation in cold regions.

- High grinding efficiency: the grinding unit applies our novel design – agitator discs with special structure, arranged in reasonable order – so that the issues of tradition bead mills, such as uneven distribution of grinding beads, or disability of driving grinding beads at low rotational speed, no longer exist, energy efficiency and grinding efficiency are thus promoted.

Applications

Industrial mass productions of water-based, oil-based materials and other materials with low viscosity.

Specifications

| Model | Power (KW) | Grinding Chamber Volume (L) | Grinding Bead Diameter (MM) | Dimensions (MM) | Weight (KG) |

RTSM-15AJ | 22 | 10 | 0.3-2.0 | 1460*1000*1400 | 650 |

RTSM-30AJ | 30/22 | 60 | 0.3-2.0 | 1950*1250*1650 | 900 |

RTSM-60AJ | 45/55 | 60 | 0.3-2.0 | 2000*950*1900 | 1500 |

RTSM-100AJ | 55/75 | 100 | 0.3-2.0 | 2600*1300*2100 | 3000 |

RTSM-300AJ(P) | 90/100 | 300 | 0.3-2.0 | 3600*1800*2500 | 4900 |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos