Aseptic Filler

| Model | Capacity (kg/h) | Filling Heads | Electricity Consumption (kw) | Steam Consumption | Compressed Air Consumption (kg/h) | Dimensions |

| JD-WJGZ-1 | 1000 | 1 | 1.5 | 100 kg /h | 0.3 | 1600×1200×2800 |

| JD-WJGZ-2 | 2000 | 1600×1200×2800 | ||||

| JD-WJGZ-3 | 3000 | 1600×1200×2800 | ||||

| JD-WJGZ-6 | 6000 | 2 | 7.5 | 200 kg /h | 0.6 | 2800×1800×2800 |

| JD-WJGZ-8 | 8000 | 2800×1800×2800 | ||||

| JD-WJGZ-10 | 10000 | 4200×1800×2800 | ||||

| JD-WJGZ-12 | 12000 | 4200×1800×2800 |

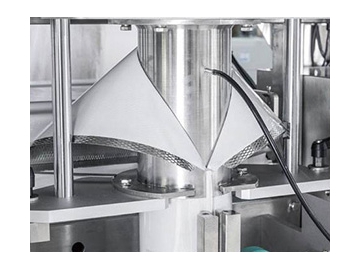

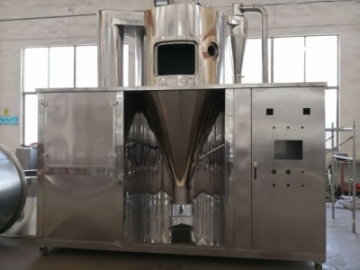

Connection with the sterilizer can be established. The aseptic filling machine automatically seals the lid when the predetermined setting volume has been reached. The filling chamber maintains a temperature of 95℃ to create an ideal aseptic environment for the filling process. The steam-spraying method is utilized for the sterilization of caps, bag openings, and filling cavities.

The filling head has a label-printing machine and an automated weighing system with electronic sensors. We offer an automated control program that can be independently linked to the CIP installation. This program comes with self-rectification and can be utilized for the safe regulation of sterilizing temperatures. Additional control is available for the automated cleaning and sterilization of the filling head and its affiliated pipes.

As a professional aseptic filling machine manufacturer and supplier in China, we also provide automatic straight line paste filling machine, coil type ultra-temperature flash sterilizer, vacuum mixing system, falling film vacuum evaporator, and more.