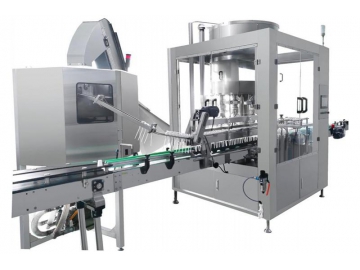

Screw-On Capper

Request a Quote

Capping Equipment

Automatic capping machine for closing plastic and glass bottles with screw caps

Screw-on capper is used to tighten caps on plastic bottles and glass bottles (such as molded bottles or tube bottles). The capping machine mainly consists of a touch screen, PLC, capping head, electrical control system, and support frame. This automatic capper typically operates on a rotary principle, allowing for easy adjustment of the tightness of the caps. It can close 20-60 bottle caps per minute. Capping machines are available in semi-automatic and fully automatic configurations, and can be configured with suitable equipment based on specific needs.

Screw Capping Machines We Offer

- Tabletop Servo Screw Capping Machine XGA-100

- Tabletop Pneumatic Bottle Capper SCM-100

- Automatic Benchtop Filling and Capping Machine SXF-100

- Automatic Servo Screw-On Capper SCM-300

- Automatic High Speed Screw Capping Machine SCM-400

- Automatic Starwheel Capping Machine SCM-600

Applications

- Screw-on capper is widely applied in packaging production lines of industries such as pharmaceuticals, cosmetics, and food.

Specifications

| Screw Cap Control | Servo motor |

| Screw Cap Diameter | 20-80 mm (customizable) |

| Production Capacity | 20-60 bottles/min |

| Bottle Size | Ø90mm×240mm (H) (customizable) |

| Air Source | 0.4-0.8Mpa |

| Power Source | AC220V; 50HZ; 1Phase |

| Control System | Touch screen PLC |

Features

- Efficient and Stable: screw-on capper can work continuously and steadily, suitable for large-scale production.

- Easy Operation: screw capping machine is easy to operate and can be quickly mastered.

- Strong A daptability: screw-on capper can adapt to different sizes and shapes of bottles and caps, featuring convenient adjustment.

- Easy to Clean and Maintain: it prolongs the equipment's lifespan.

- Customizable: Suitable capping equipment can be custom-made according to specific bottle and cap requirements.

Optional

- Customized capping heads

- Cap sorting machine (vibrating tray, elevator)

- Bottle unscrambler machine

- Starwheel

- Filling machine

FAQ

Screw-on capper is suitable for closing plastic and glass bottles with screw caps. In order to accurately determine suitability, the buyer needs to provide photos of the bottles and caps, bottle dimensions, cap dimensions, and other necessary information, and contact our sales team for assistance in confirming the appropriate machine configuration.

While local service points are limited, buyers may seek assistance from local dealers, if available. Prior to leaving the factory, the machine undergoes complete assembly and testing and is shipped fully assembled, requiring no special installation or debugging. Simply power on the machine for use and reference the manual or instructional videos for parameter settings. In the event of any issues, contact the seller for online guidance and support.

Screw-on capper comes with a 12-month warranty, excluding consumable parts. Within the warranty period, replacement parts are provided at no additional cost (excluding shipping expenses), while reasonable fees apply for parts outside the warranty coverage. Lifetime free remote technical support is also offered for the equipment.

Contact us promptly for assistance in resolving the issue. We can conduct real-time remote fault diagnosis and promptly ship replacement parts if needed.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos