Magnetic Pump Liquid Filling Machine

Request a Quote

Filling Equipment

Magnetic pump filler for measuring and dispensing liquids into containers

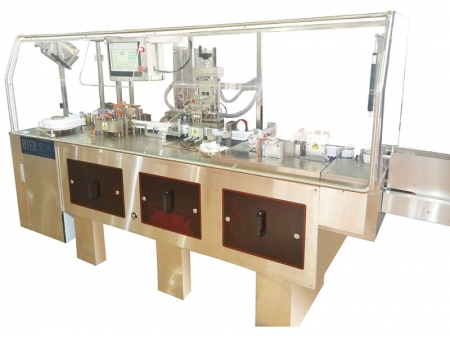

The magnetic pump liquid filling machine uses high-precision miniature magnetic pumps, pump speed, and pump working time to determine the filling volume. This filler is widely applicable and can fill almost all fluid substances that can flow, especially suitable for filling oils, detergents, acids, alkalis, and highly corrosive liquids.Magnetic pump filler can meet the requirements of filling capacities ranging from 5ml to 3000ml and is not limited by the filling capacity, making it a reliable and durable filling equipment.

Magnetic Pump Liquid Filling Machine We Offer

- Semi-Auto Benchtop Piston Filler

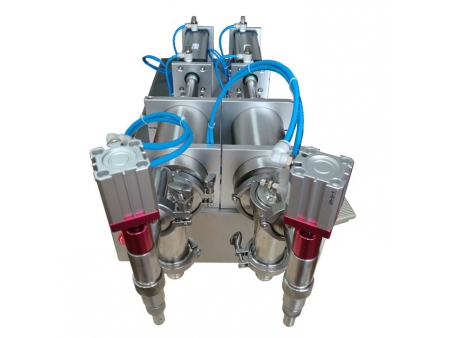

- Automatic Benchtop 4-Head Magnetic Pump Liquid Filler

- Automatic 4-Head Magnetic Pump Liquid Filling Machine

Applications

- Magnetic pump liquid filling machine can be applied in industries such as cosmetics, beverages, medicine, chemicals, medical, and food, significantly improving production capacity and product quality.

- Magnetic pump filler is an ideal equipment for filling low-viscosity liquids such as oils, perfumes, juices, milk, beverages, inks, and water in bottles, cans, and jars.

- Magnetic pump filler is suitable for both large-scale production requirements in factories and small-scale production applications in laboratories, workshops, and similar settings.

Specifications

| Model | YH100-4H |

| Filling Capacity | 5-3000ml |

| Filling Accuracy | ±0.5-1.0% |

| Production Capacity | 100ml: ≤60BPM (affected by liquid, filling volume, etc.) |

| Max. Flow Rate | 3L/min per pump |

| Pump Type | Magnetic gear pump (peristaltic pump is optional) |

| Pump Material | Stainless steel 304 (gear material PEEK) |

| Nozzle Quantity | 4 (or customizable) |

| Nozzle Diameter | 8mm (or customizable) |

| Conveyor Belt Width | 80mm (chain plate conveyor with other sizes is customizable) |

| Conveyor Length | 1500mm |

| Dimensions (L×W×H) | 1500×400×1100mm |

| Air Source | 0.4-0.6Mpa |

| Power Source | AC220V; 50Hz; 1Phase |

| Machine Material | Stainless steel 304 |

| Control Method | Touch screen |

| Working Mode | Automatic |

Features

- Excellent touch screen, PLC, motors, and electrical components are used to ensure the long-term stable operation of the magnetic pump filler. The user interface is simple and intuitive, allowing the equipment to be operated proficiently without the need for professional personnel.

- Magnetic pump filler allows for fully automated production, including automatic bottle feeding, automatic bottle positioning through sensors, automatic filling, and automatic product output. The filling process stops automatically in the absence of bottles, preventing material waste.

- The standard configuration includes a magnetic gear pump as the metering pump, with optional choices such as peristaltic pumps, gear pumps, and ceramic pumps for metering purposes.

- Each metering pump's filling volume and speed can be independently adjusted and set.

- Dual-speed filling is adopted, with a fast initial speed followed by a slower speed, significantly reducing foaming during the filling process, preventing material overflow, and improving filling accuracy.

- The filling system utilizes a lifting-type filling head, anti-drip and anti-reflux design, ensuring precise filling.

- The chain plate conveyor features strong load-bearing capacity, wear resistance, corrosion resistance, durability, no deformation, and easy cleaning, ensuring smooth and steady bottle conveying during filling.

- The conveyor is equipped with an independent speed control system, facilitating the adjustment of speed matching between front and rear production equipment.

- Innovative safety designs include a concealed lifting device for the filling head, motor design, and stainless steel protective baffles added to the front and rear bottle-blocking cylinders, significantly enhancing safety during use and improving equipment quality.

- Magnetic pump liquid filling machine features four nozzles for simultaneous filling and can be customized with other nozzles according to requirements.

Optional

- Optional capping or screw-on capping device.

- Optional 4, 6, 8-head filling machine.

FAQ

Magnetic pump liquid filling machine is suitable for low-viscosity aqueous liquids. To accurately determine suitability, the buyer needs to provide necessary information such as the name of the material, its fluidity, filling volume, etc. and contact our sales team for assistance in confirming the appropriate machine configuration.

While local service points are limited, buyers may seek assistance from local dealers, if available. Prior to leaving the factory, the machine undergoes complete assembly and testing and is shipped fully assembled, requiring no special installation or debugging. Simply power on the machine for use and reference the manual or instructional videos for parameter settings. In the event of any issues, contact the seller for online guidance and support.

Magnetic pump liquid filling equipment comes with a 12-month warranty, excluding consumable parts. Within the warranty period, replacement parts are provided at no additional cost (excluding shipping expenses), while reasonable fees apply for parts outside the warranty coverage. Lifetime free remote technical support is also offered for the equipment.

Contact us promptly for assistance in resolving the issue. We can conduct real-time remote fault diagnosis and promptly ship replacement parts if needed.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos