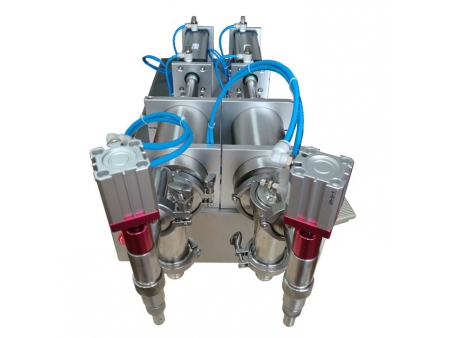

Bakery Filling Machine (Dosing Cream Injecting Machine)

Request a Quote

Filling Equipment

Volumetric filling machine for injecting, layering and decoration of confectionary products with cream or other stuffing

YH-500 series bakery filling machine allows for accurate and automatic quantitative dispensing of paste, semi-fluid, and liquid materials. Dosing cream injecting machine is a small-sized, powerful, and widely applicable device with a filling capacity of 30-5000ml. By slightly adjusting the equipment according to the actual need, it can meet the user's practical filling requirements.

Bakery Dosing and Injecting Machines We Offer

- Tabletop Cream Injecting Machine (Cream Filler / Jam Filler / Chocolate Filler)

- Cream Filling & Decoration Machine with Conveyor

- Cake Icing & Decoration Machine with Multi-Station Turntable

Applicable Products

Bakery filling machine is ideal for filling of semi-fluid materials with poor flowability, such as honey, chocolate, silicone, butter, yogurt, sesame paste, mashed potatoes, mixed porridge, jelly and jam etc.

Applications

- Bakery filling machine is suitable for use in bakeries, cake shops, western restaurants, cafes, food processing plants, etc.

- Bakery filling machine is used for coating products such as spreading cream on cakes or for pastry decoration.

- Bakery filling machine is used for injecting various food such as bread, cake, and cream puffs. A hollow needle is inserted into the product to directly inject the stuffing without damaging the appearance of the product.

- Bakery filling machine is used for quantitative filling of products, such as filling honey.

Specifications

| Model | YH-500 |

| Filling Capacity | 30-5000ml |

| Production Capacity | ≤60BPM (affected by filling volume, flow rate, fluidity, etc.) |

| Pump Type | Rotor Pump |

| Pump Material | Stainless steel 304 |

| Nozzle Quantity | 1 (or customizable) |

| Nozzle Diameter | 10mm (or customizable) |

| Hopper Capacity | 20L |

| Dimensions (L×W×H) | 1140×400×330mm |

| Air Source | 0.4-0.6Mpa |

| Power Source | AC220V; 50Hz; 1Phase |

| Machine Material | Stainless steel 304 |

| Control Method | Touch screen |

| Working Mode | Automatic |

Features

- High-quality touchscreen, PLC, motors, and electrical components are used to ensure the long-term stable operation of the filling machine. The human-machine interface is simple and intuitive, allowing the equipment to be used proficiently without the need for professional personnel.

- The filling system adopts an anti-drip design for more accurate filling.

- The bakery filling machine is equipped with a counting function to facilitate production statistics for users.

- The entire machine is made of stainless steel 304, with a brushed surface treatment for a more attractive appearance. It is easy to clean, sterilize, and has no sanitary dead corners, complying with the HACCP and GMP requirements of the food and pharmaceutical industries.

Optional

- Customized filling nozzles

- Optional SUS316 material for material contact parts

FAQ

Bakery filling machine is suitable for semi-fluid materials. To accurately determine suitability, buyers need to provide necessary information such as the name of the material, its flowability, filling volume, etc. Please contact our sales team for assistance in confirming the appropriate machine configuration.

While local service points are limited, buyers may seek assistance from local dealers, if available. Prior to leaving the factory, the machine undergoes complete assembly and testing and is shipped fully assembled, requiring no special installation or debugging. Simply power on the machine for use and reference the manual or instructional videos for parameter settings. In the event of any issues, contact the seller for online guidance and support.

Bakery filling machine comes with a 12-month warranty, excluding consumable parts. Within the warranty period, replacement parts are provided at no additional cost (excluding shipping expenses), while reasonable fees apply for parts outside the warranty coverage. Lifetime free remote technical support is also offered for the equipment.

Contact us promptly for assistance in resolving the issue. We can conduct real-time remote fault diagnosis and promptly ship replacement parts if needed.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos