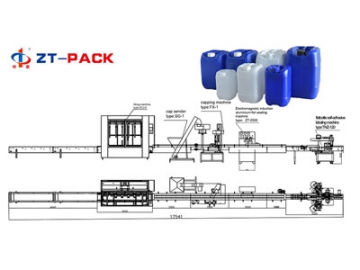

Drum & Tote Filling Machine

Request a Quote

Filling Equipment

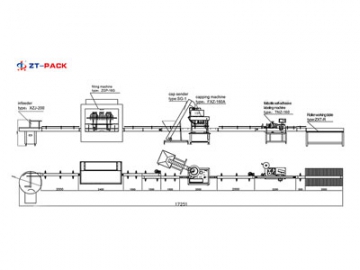

Pallet filling system for calibrated filling of drums on pallets and IBC totes

Drum & toe filling machine is a packaging equipment used in industries such as chemical, food, and pesticide for the quantitative weighing of materials based on their weight. Drum filler is made of stainless steel and consists of a spray gun device, system control unit, electronic scale platform, mechanical structure, and conveyor. The filling machine comes with a filling accuracy of ±0.1%, a complete structure, stable and reliable performance, and can be adjusted to meet the actual needs of customers according to various operating conditions and production capacities.

Drum & Tote Filling Machine We Offer

- Automatic Palletized Drum Filling Machine (100-1500kg)

- Quad Drum Filler (10-1500kg)

- Single Drum Filler (10-300kg)

- Single Drum Filler (10-100kg)

- Small Drum filling Machine (1-10kg)

Applications

- Drum & toe filling machine is suitable for quantitative filling of flowable materials, including paint, adhesive, resin, polyurethane, diluent, curing agent, solvent, additive, glycerin, lubricating oil, alcohol, and other hazardous chemical products.

Specifications

| Model | ADF-1200L4/BDF-1200L4 | ADF-1200D4/BDF-1200D4 |

| Nozzle Quantity | 1 | 1 |

| Filling Mode | Top filling | Below-surface filling |

| Filling Capacity | 20-1500kg/drum | 20-1500kg/drum |

| Drum Size | 200L drums × 4 or 1000L drums on pallet | 200L drums × 4 or 1000L drums on pallet |

| Production Capacity | 40-60BPH | 30-50BPH |

| Filling Accuracy | ±0.1% | ±0.1% |

| Infeed Conveyor (L×W) | 1500×1500mm (optional) | 1500×1500mm (optional) |

| Filling Scale (L×W) | 1500×1500mm (optional) | 1500×1500mm (optional) |

| Outfeed Conveyor (L×W) | 1500×1500mm (optional) | 1500×1500mm (optional) |

| Capping Device | Manual capping tool (optional) | Manual capping tool (optional) |

| Power Source | AC380V; 50Hz; 3Phase | AC380V; 50Hz; 3Phase |

| Air Source | 4-6kg/m² | 4-6kg/m² |

| Explosion-Proof Level | ADF-1200L4 non explosion-proof BDF-1200L4 explosion-proof level: Exd II BT6 | ADF-1200D4 non explosion-proof BDF-1200D4 explosion-proof level: Exd II BT6 |

| Dimensions (L×W×H) | 4600×1960×2365mm | 1800×3204×3180mm |

Depending on the design of different machine models, drum & toe filling machine has some or all of the following functions

- Product settings: the filling machine can store up to 10 different product weights and related parameter settings for quick product switching.

- Multi-speed filling: the filling speed of the equipment can be divided into two stages (fast/slow) or three stages (slow/fast/slow) to significantly improve filling accuracy.

- Throttling device: it prevents material splashing when filling low-viscosity materials due to the high initial pressure of the feeding pump.

- Drip-proof: high viscosity spray guns solve the problem of dripping in the filling of high viscosity products; low viscosity spray guns are equipped with drip-proof oil cups.

- Filling mode: optional filling at the top of the drum, filling at the liquid level inside the drum, and filling below the liquid level. Users can set the spray gun lifting speed based on the foaming degree of the material.

- Easy operation: one-button filling, net weight/gross weight mode, automatic/manual mode, and other functional modes can be freely switched.

- Data statistics: weight accumulation, counting accumulation, optional computer connection for data management convenience.

- Automatic hole alignment: the filling ports of round containers are often eccentric holes, and this filling device solves the inconvenience of manual alignment.

- Human-machine interface: some filling machine models are equipped with a touch screen terminal for easy setting of filling parameters and calibration of the scale.

- Explosion-proof system: optional integral cast iron aluminum explosion-proof electrical control box, with an explosion-proof rating of Exd II BT4 and a protection rating of IP65.

- Customized design: drum & toe filling machine can be customized based on the user's on-site raw material characteristics and container dimensions.

Optional

- Standard platform structure with optional powered roller conveyor.

- Standard material is carbon steel with spray painting, and full stainless steel structure is available as an option.

FAQ

Drum & toe filling machine is suitable for quantitative filling of most flowable materials. To accurately assess suitability, buyers need to provide the material's name, filling quantity, photos of the containers, and whether explosion-proof is required. Contact our sales team for assistance in confirming the appropriate machine configuration.

Generally, around 8-10 years. Well-maintained equipment with daily care has a longer lifespan. The equipment runs stably and is durable.

While local service points are limited, buyers may seek assistance from local dealers, if available. Prior to leaving the factory, the machine undergoes complete assembly and testing and is shipped fully assembled, requiring no special installation or debugging. Simply power on the machine for use and reference the manual or instructional videos for parameter settings. In the event of any issues, contact the seller for online guidance and support.

Drum & toe filling machine comes with a 12-month warranty, excluding consumable parts. Within the warranty period, replacement parts are provided at no additional cost (excluding shipping expenses), while reasonable fees apply for parts outside the warranty coverage. Lifetime free remote technical support is also offered for the equipment.

Contact us promptly for assistance in resolving the issue. We can conduct real-time remote fault diagnosis and promptly ship replacement parts if needed.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos