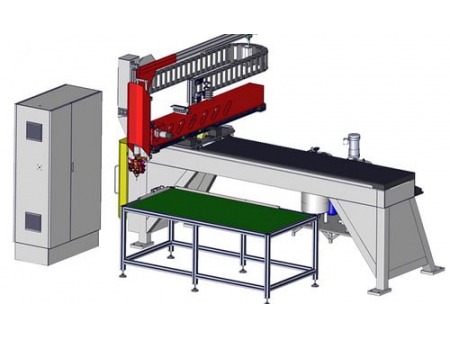

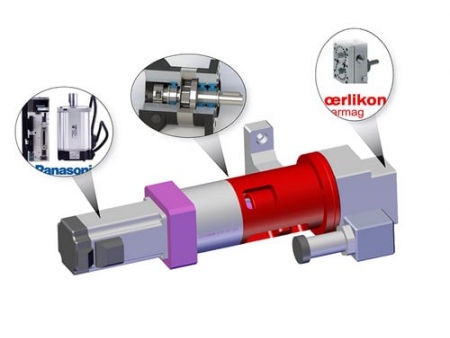

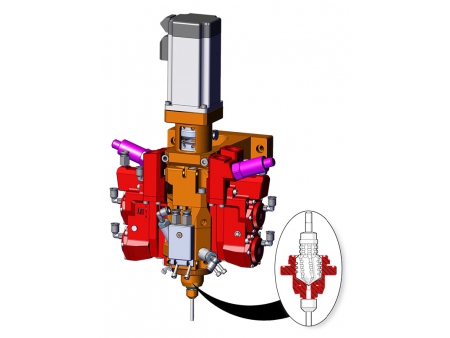

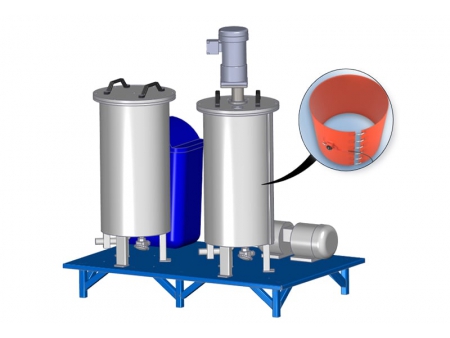

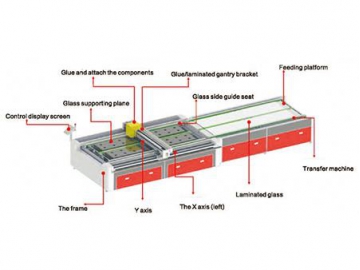

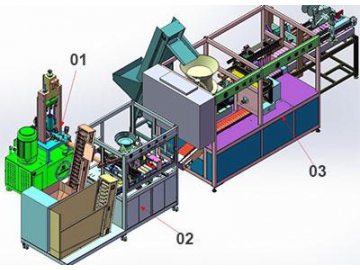

Polyurethane foam-in-place gasketing machine (5-30mm) is a split system independently designed and produced by SHANJIA. It features an instant nozzle-closing mechanism to prevent material drips and blockages, alongside automated cleaning and pressure control functionalities. Its mixing chamber's modular design simplifies maintenance and minimizes reliance on quick-wear parts. Furthermore, the inclusion of globally sourced, high-quality components enhances the formed-in-place gasket machine's overall stability, making it a robust solution for a wide range of gasketing and sealing applications.

- Application rate 0.3-5g/s

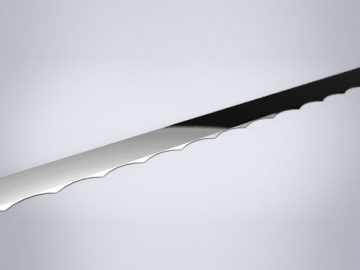

- Gasket width 5-30mm (4mm in groove)

- Travel speed 0-30 m/min

The automatic polyurethane foam-in-place gasketing machine can be applied to the sealing of auto parts and components of energy storage system, electronic devices, home appliances, cooling systems, air cleaners, etc.

| Travel Range (X/Y/Z) | 2250×1250×200mm (customizable) |

| Dimensions | 2500×2200×2200mm (customizable) |

| Weight | 1600kg |

| Total Power | 3-4kW |

| Gasket Width | 5-30mm (adjustable within the range) |

| Mixing Ratio | 1:1-10:1 |

| Application Rate | 0.3-5 g/s |

| Travel Speed | 0-30 m/min |

| Working Temperature | -15°C to 35°C |

| Metering Accuracy | ±0.005 |

| Pressure Limit & Alarm | 0-4 Mpa |

| Filtration Accuracy | 40-50 µm |

| Repeat Accuracy | ±0.05mm |

| Air Pressure | ≧0.6Mpa |

| Frequency | 50HZ |

| Voltage | Three-phase five-wire 380V |

- A linear robot with an intelligent control system switching between 2D and 3D mode.

- CNC multi-axis programming guides the machine's movements and achieves complex workpiece handling while ensuring precision.

- Intelligent parameter storage allowing for flexible movement paths.

- Reliable fault alarm system automatically stops the machine in case of errors, remote trouble shooting and real-time monitoring of gasketing materials can be achieved.

- Intelligent verification of the density of foam gaskets, accurate modification of foam gasket stiffness, and support for various foam gasket brands for optimal performance.

- Customizable ports tailored to specific operational requirements.

- Compatible with Industry 4.0 MESTIntel and other systems.

- Optional security barriers available to create a safer workplace.

- Custom color options for major parts of the machine.