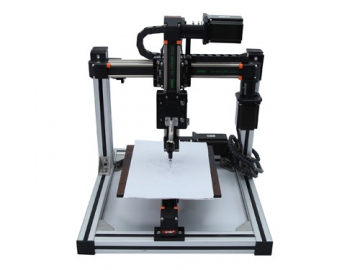

Robotic dispensing cell for gluing and sealing applications

As a specialist manufacturer of formed-in-place foam gasket machines, we have developed an adhesive dispensing robot that can automatically dispense adhesive on various products, particularly for components with complex contours.

Our control system seamlessly integrates with the six-axis robot adhesive dispensing system, which supports one-, two-, and multi-component polymer materials with a wide range of viscosities, ensuring optimal sealing and gasketing performance.

- Application rate 0.3-5g/s

- Gasket width 5-30mm (initiative in domestic market)

- Travel speed 0-30 m/min

Applications

This six-axis robot adhesive dispensing system is extensively utilized in 3-dimensional dispensing applications for auto parts, energy storage products, electronic devices, etc.

Specifications

| Travel Range (X/Y/Z) | 2250×1250×200mm (customizable) |

| Dimensions | 2500×2200×2200mm (customizable) |

| Weight | 1600kg |

| Total Power | 3-4kW |

| Gasket Width | 5-30mm (adjustable within the range) |

| Mixing Ratio | 1:1-10:1 |

| Application Rate | 0.3-5 g/s |

| Travel Speed | 0-30 m/min |

| Working Temperature | -15°C to 35°C |

Features

- A linear robot with an intelligent control system switches freely between 2D and 3D mode.

- CNC multi-axis programming helps accommodate complex component geometries.

- Intelligent parameter storage allows for flexible movement along any path.

- Intelligent verification of the density of foam gaskets, accurate modification of foam gasket stiffness, and support for various foam gasket brands for optimal performance.

- Customizable ports tailored to specific operational requirements.

- Compatible with Industry 4.0 MESTIntel and other systems.