- Types

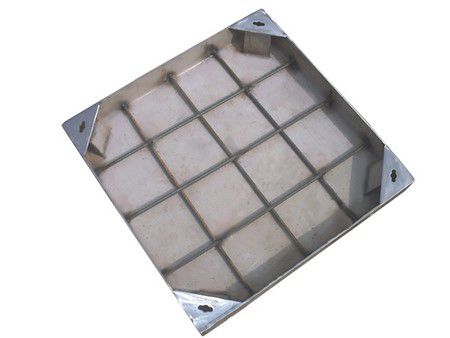

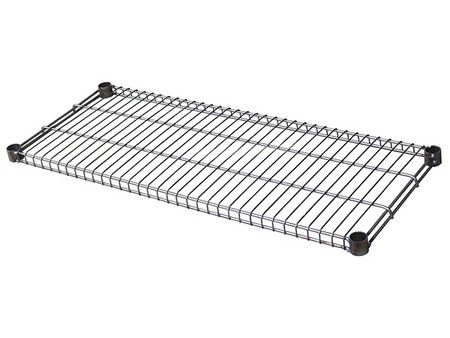

- Samples

- Specifications

- Features

- Work Site

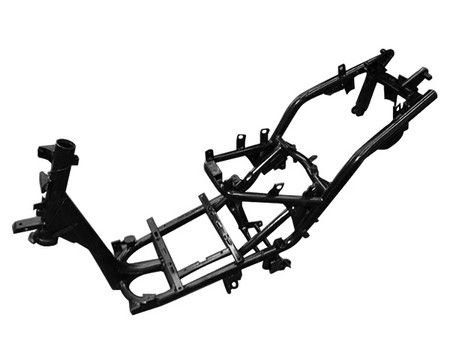

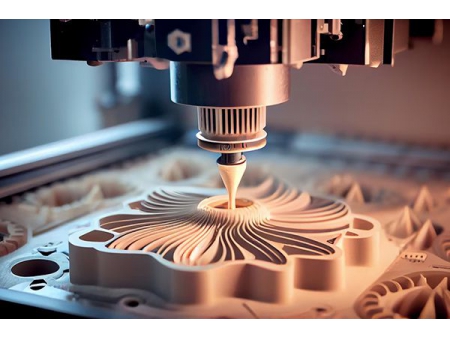

6-axis robotic arms have a wide range of applications, including the aerospace industry, automotive and parts manufacturing, electronics and 3C manufacturing, food, beverage and pharmaceutical industries, warehousing and logistics, rubber and plastics handling and processing, stone and wood product processing and carving, casting and forging, metal processing, including welding and loading/unloading, as well as non-standard applications in other fields.

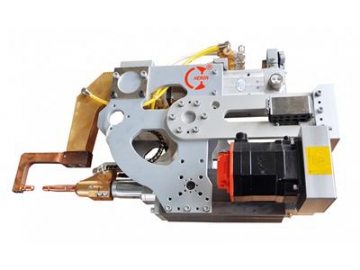

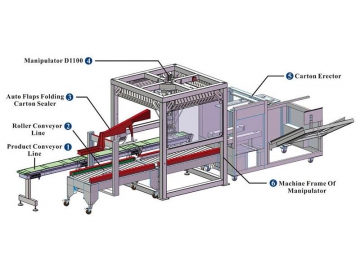

At Hwashi technology, our six-axis articulated robots can be combined with welding positioners, custom tooling fixtures, slides, material handling robots, and complementary processing equipment (such as punch presses, laser cutting machines, hydraulic presses) to form an automated welding production line.