Mold Fabrication

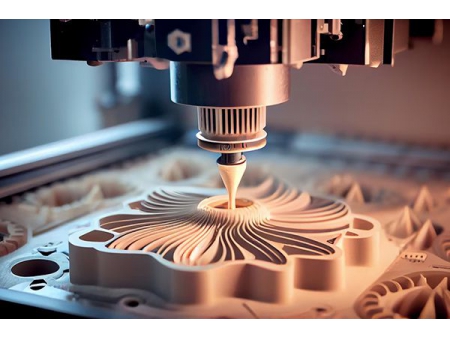

We hold core competencies in mold fabrication and employ professional mold designers, advanced software technology, and complete professionals and equipment to create high-quality molds for plastic parts production.

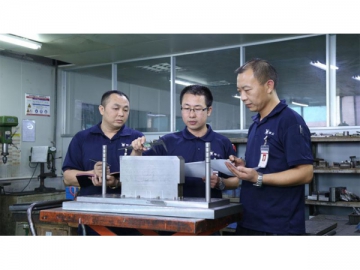

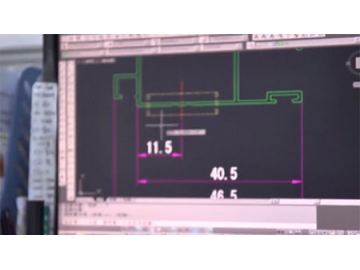

Our technical specialist will collaborate with you to create a mold that satisfies your exact needs and requirements. Our experienced design team produces precise mold designs in accordance with your product specifications. With the help of our advanced software, 3D modeling, simulation analysis, and optimization of molds are possible for enhanced production efficiency and quality.

- Our senior product design team is experienced in using APQP, PMP, and other project management tools effectively for design development.

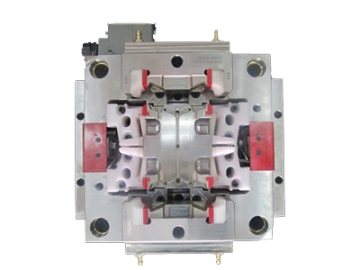

- We use cutting-edge technology to produce precision part molds with accuracy down to 0.02mm and a service life of over 1 million cycles.

- We boast an impressive line of production equipment, ranging from first-class injection molding machines and vacuum forming and pressure forming tools to automated manipulators and MES systems. In total, we have over 100 complete sets of tools to ensure the highest quality results.

Our experienced R&D team of more than 25 people, with over 20 years of experience in the design and production of plastic products, plastic mold, silicone and rubber products, ensures high-quality services. We are experienced in mold design, flow analysis, DFM, mold production, assembly and plastic product manufacture to ensure a 0.02mm accuracy level. We strive to continuously optimize our services by learning from customers' mold design and product manufacturing standards.

We offer highly advanced injection molding equipment to guarantee that the mold meets quality standards and provides an excellent solution to meet your needs. Our equipment includes:

1600-ton Large Injection Molding Machine

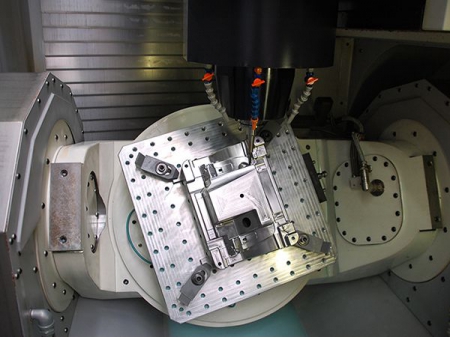

1600-ton Large Injection Molding Machine 5-axis High Precision CNC

5-axis High Precision CNC High-Speed CNC

High-Speed CNC Vacuum Forming Machine

Vacuum Forming Machine Hydraulic Press

Hydraulic Press Open Mill

Open Mill Robotic Arm/Automatic Inspection

Robotic Arm/Automatic Inspection Wire EDM

Wire EDM

At RZD, you can customize precision molds to your exact specifications. We provide you with all the necessary details of the parameters to ensure a perfect fit for your unique needs.

- Surface Roughness: 0.03 μm

- Minimum R Corner: 0.015 mm

- Service Life: over 1 million cycles

- Mold Material: To withstand the pressures in the injection molding process, the mold is made from a combination of high-strength aluminum and steel components.

IATF 16949 and ISO 9001 Quality Management System Certifications