Suppository Filling and Sealing Machine

Request a Quote

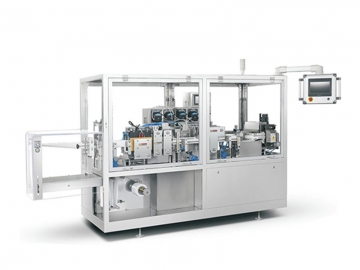

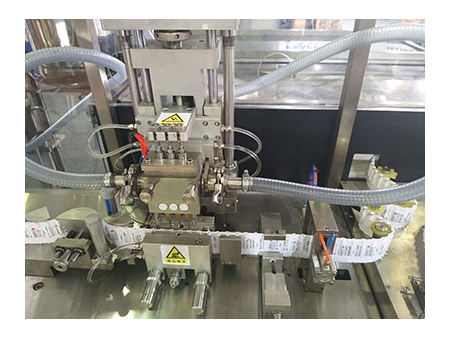

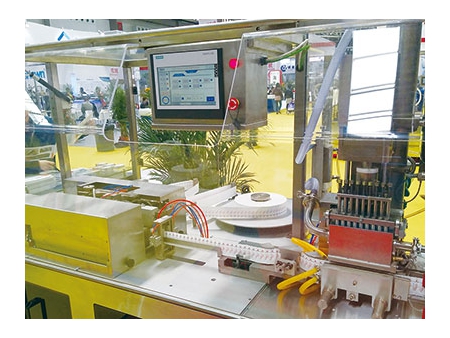

Dier suppository filling and sealing machine is designed for production of suppositories for the pharmaceutical industry. Rolls of PVC or PE/PVC sheets are blown and formed into shells where the equally mixed liquid drug will be precisely filled in. Once filled, the shells are transported into cooling unit to convert drugs from liquid to solid with required shape.

Choose Your Model

- Model: GZS-15A type

- Output: 26000-30000 granulations/hour

- Weight per granulation: 0.5-3.7g

- Dosage difference: ±2%

- Dimension: 7400*2100*2400mm

- Machine weight: 2500kg

- Suppository forms: Bullet-head form, torpedo form, duck-mouth form and other special forms

- Adapting group: Demi-synthesis fatty acid lipo-glycerol, glycerol gelatin, polyethylene glycol etc.

- Drug liquid tank capacity: 70L

- Loading height: 2000mm

- Power voltage: Three phase AC 380V(3-PHASEAC)

- Total power: 21KW

- Air pressure: 0.5MP

- Air consumption: 1.6 m³/min

- Water consumption: 600L/h (recycling)

- Model: GZS-15U type

- Output: 18000-24000 granulations/hour

- Weight per granulation: 0.5-3.7g

- Dosage difference: ±2%

- Dimension: 4500*5700*2000mm

- Machine weight: 2500kg

- Suppository forms: Bullet-head form, torpedo form, duck-mouth form and other special forms

- Adapting group: Demi-synthesis fatty acid lipo-glycerol, glycerol gelatin, polyethylene glycol etc.

- Drug liquid tank capacity: 70L

- Loading height: 2000mm

- Power voltage: Three phase AC 380V

- Total power: 21KW

- Air pressure: 0.5MP

- Air consumption: 2m³/min

- Water consumption: 1000L/h (recycling)

- Model: GZS-9A type

- Output: 18000-22000 granulations/hour

- Weight per granulation: 0.5-3.7g

- Dosage difference: ±2%

- Dimension: 4800*2040*2400mm

- Machine weight: 2000kg

- Suppository forms: Bullet-head form, torpedo form, duck-mouth form and other special forms

- Adapting group: Demi-synthesis fatty acid lipo-glycerol, glycerol gelatin, polyethylene glycol etc.

- Drug liquid tank capacity: 70L

- Loading height: 2000mm

- Power voltage: Three phase AC 380V

- Total power: 17KW

- Air pressure: 0.5MP

- Air consumption: 1.5 m³/min

- Water consumption: 600L/h (recycling)

- Model: ZS-linear type

- Output: 8000-10000 granulations/hour

- Weight per granulation: 0.5-5g

- Dosage difference: ±2%

- Dimension: 6900*1500*1800mm

- Machine weight: 1900kg

- Suppository forms: Bullet-head form, torpedo form, duck-mouth form and other special forms

- Adapting group: Demi-synthesis fatty acid lipo-glycerol, glycerol gelatin, polyethylene glycol etc.

- Drug liquid tank capacity: 50L

- Loading height: 1600mm

- Power voltage: Three phase AC 380V

- Total power: 13KW

- Air pressure: 0.5MP

- Air consumption: 1.5 m³/min

- Water consumption: 600L/h (recycling)

- Model: ZS-U type

- Output: 8000-10000 granulations/hour

- Weight per granulation: 0.5-5g

- Dosage difference: ±2%

- Dimension: 3490*2900*2000mm

- Machine weight: 1700kg

- Suppository forms: Bullet-head form, torpedo form, duck-mouth form and other special forms

- Adapting group: Demi-synthesis fatty acid lipo-glycerol, glycerol gelatin, polyethylene glycol etc.

- Drug liquid tank capacity: 50L

- Loading height: 1600mm

- Power voltage: Three phase AC 380V

- Total power: 13KW

- Air pressure: 0.5MP

- Air consumption: 1.5 m³/min

- Water consumption: 600L/h (recycling)

- Model: ZS-3A type

- Output: 6000-8000 granulations/hour

- Weight per granulation: 0.5-3.7g

- Dosage difference: ±2%

- Dimension: 2700*1720*2300mm

- Machine weight: 1200kg

- Suppository forms: Bullet-head form, torpedo form, duck-mouth form and other special forms

- Adapting group: Demi-synthesis fatty acid lipo-glycerol, glycerol gelatin, polyethylene glycol etc.

- Drug liquid tank capacity: 50L

- Loading height: 2000mm

- Power voltage: Three phase AC 380V

- Total power: 9KW

- Air pressure: 0.5MP

- Air consumption: 1.50m³/min

- Water consumption: 600L/h (recycling)

- Model: BZS-semi auto type

- Output: 5000-6000 granulations/hour

- Weight per granulation: 0.5-5g

- Dosage difference: ±2%

- Dimension: 4500*1700*2000mm

- Machine weight: 1000kg

- Suppository forms: Bullet-head form, torpedo form, duck-mouth form and other special forms

- Adapting group: Demi-synthesis fatty acid lipo-glycerol, glycerol gelatin, polyethylene glycol etc.

- Drug liquid tank capacity: 50L

- Loading height: 1800mm

- Power voltage: Three phase AC 380V

- Total power: 7.8KW

- Air pressure: 0.5MP

- Air consumption: 0.5m³/min

- Water consumption: 600L/h (recycling)

View Details

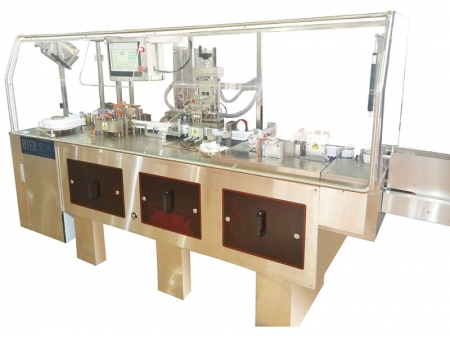

Alu & Alu suppository filling and sealing machine

Alu & Alu suppository filling and sealing machine Automatic suppository filling and sealing machine

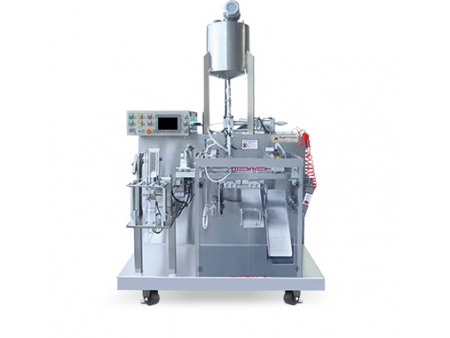

Automatic suppository filling and sealing machine GZS-9A automatic suppository filling and sealing machine

GZS-9A automatic suppository filling and sealing machine

Features

- The machine can be operated in continuous or intermittent motion, features precise filling position and high dosing accuracy.

- Suitable for filling traditional Chinese medicine suppository and gelatin matrix with higher viscosity.

- Applicable to a variety of roll materials, such as ALU/PE, PP/ALU/PE, PVC, PVC/PE, PVC/PVDC/PE.

- PLC programmable control and HMI (Human Machine Interface), providing high degree of automation and stable operation.

- Large capacity drug liquid tank features automatic control unit for constant temperature, stirring and liquid level.

- Continuous circulation system for pipeline prevents liquid drug from being solidified when machine shutdown.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos