Antibiotic Vial Filling and Rubber Stopper Machine

Request a Quote

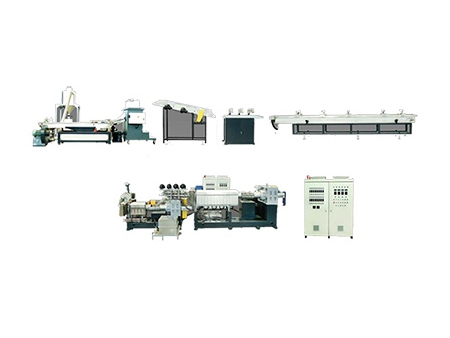

The antibiotic vial filling and rubber stopper machine is designed for filling and stoppering of 2 to 20 ml antibiotic vials. It can automatically complete the whole production process, from bottle collating, filling, stoppering, to final bottle discharging. The machine can be used independently or used in combination with vertical ultrasonic vial cleaner and vial sterilizing dryer to form a production line.

Main Characteristics

- The parts contacting the bottles can be easily installed and removed for convenient cleaning and sterilization. In addition, the parts that come into contact with antibiotic are made of 316L stainless steel or quality silicone material, and other main parts are created with quality stainless steel. Therefore, the antibiotic vial filling and rubber stopper machine fully meet GMP requirements.

- The machine provides stable operation, high efficiency and low bottle breakage.

- It uses imported sensor to realize No bottle, No filling. This effectively avoids the waste of medicine liquid.

- The equipment adopts continuous linear synchronous belt drive system, which simplifies drive structure and ensures smooth bottle delivery and low noise.

- The filling system comes standard with ceramic metering pump. Peristaltic pump or ceramic pump is also available upon request.

- The filling needle is inserted into the vial, and the antibiotic is delivered to the vial through a closed tube. This prevents the medicine liquid from coming into contact with the air, realizing aseptic filling.

- The antibiotic vial filling and rubber stopper machine adopts linear continuous stoppering method, instead of traditional rolling type stoppering method. Hence, higher stoppering qualification rate is achieved. When there is no bottle, the stopper block board will block up the stoppering channel, so as to stop the stoppering operation.

- The machine adopts advanced PLC, human-machine interface to control and monitor the operation. The system can display parameters like production speed, working time, as well as faults. It can also cooperate with control systems of washing equipment and sterilizing dryer to realize linkage control.

- It is convenient and easy to change the spare parts of the equipment, thus facilitating maintenance work.

We are a professional glass vial sterilizing dryer manufacturer in China. We also provide plastic infusion bottle welding machine, bottle capping machine, carton elevator, and much more.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos