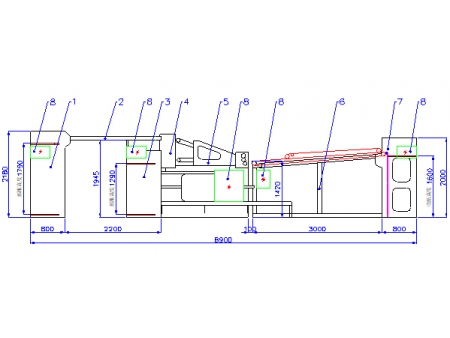

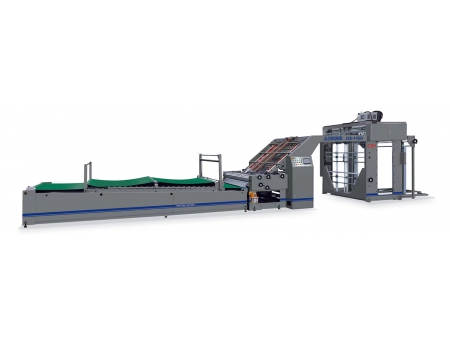

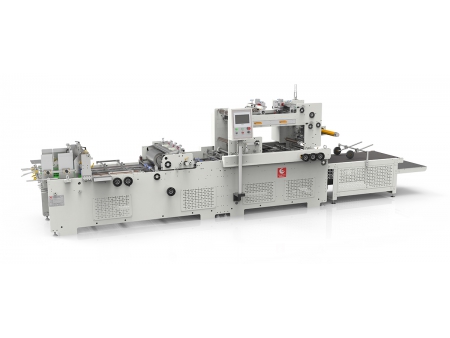

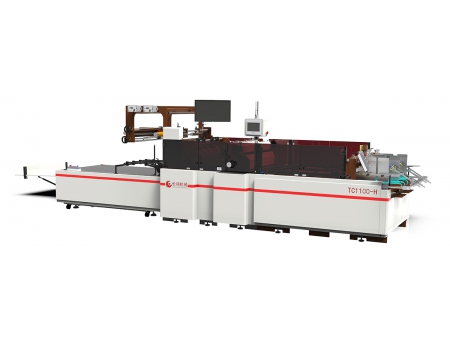

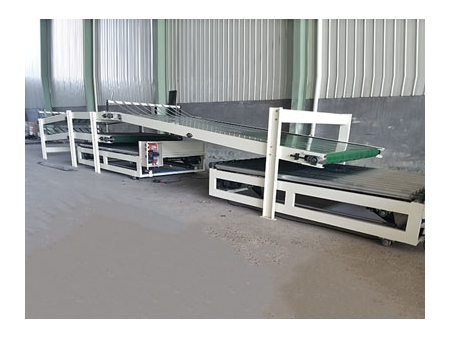

Automatic cardboard laminator is specially developed by DINGSHUNG for laminating cardboard with cardboard, as well as flute corrugated board with cardboard. Unique dynamic aligning system is equipped to ensure the high lamination accuracy to within ±0.5mm. We hold multiple invention patents for this equipment.