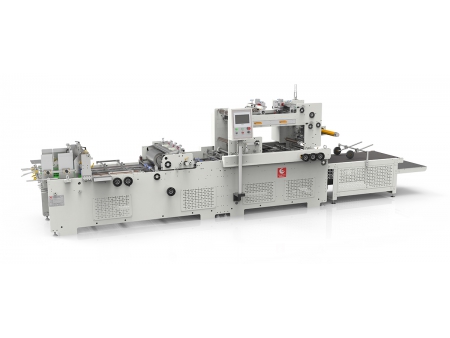

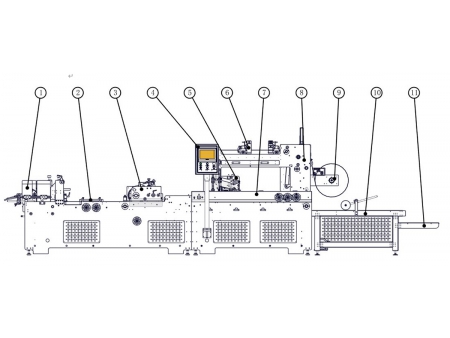

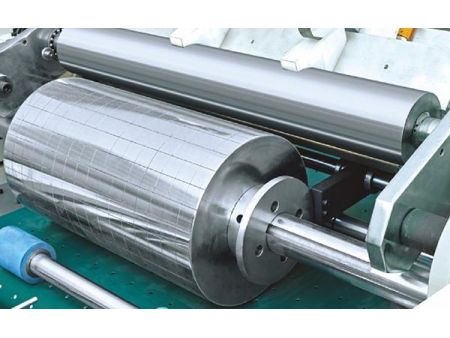

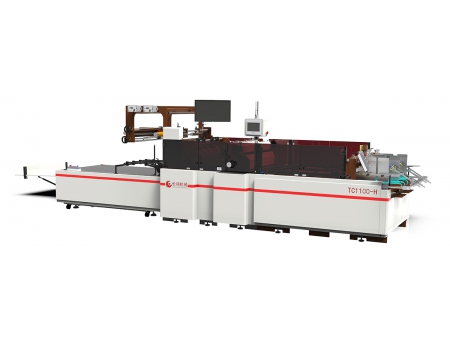

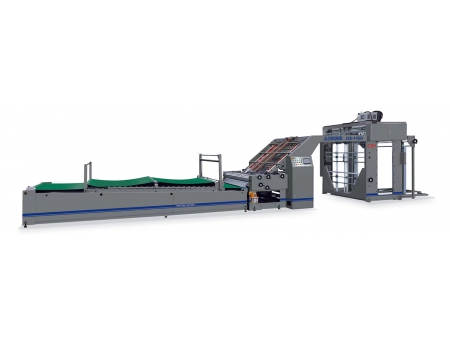

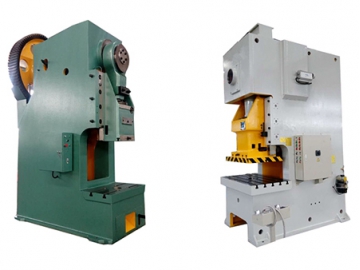

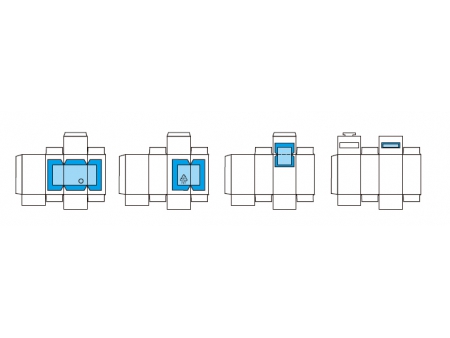

ChangHong window patcher with punching & scoring unit is the latest fully automatic machine developed by ChangHong, offering high productivity and versatility. This series window patching machines has an independent window patching station, which is equipped with a double pneumatic punching and scoring unit for V cutting and creasing. This allows for creasing lines on the film via heating and heating the film for embossing with molds, filming or other processes.

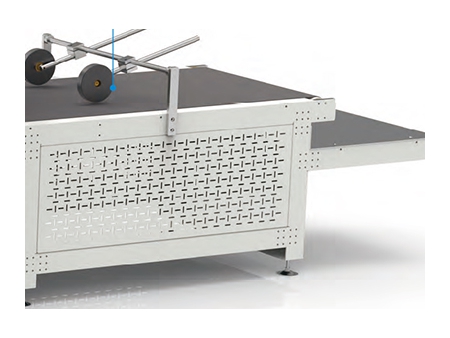

The fully automatic window patching machine comes with a maximum speed of 8000 pcs/h, and the film thickness can reach 0.1-0.45mm, with a creasing accuracy of 0.5mm. The front and rear positions of the carton blank for window patching can be adjusted via touch screen or mechanical adjustment mechanisms. The film position can be adjusted by inputting parameters on the touch screen. The gluing position can also be adjusted according to the position of the film without stopping the machine, ensuring high accuracy.