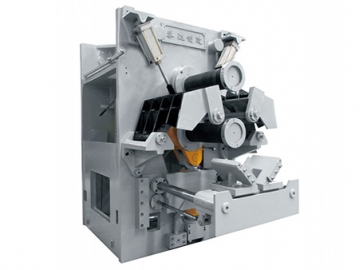

Top Loading Arm with Vapor Recovery

Request a Quote

This top loading arm is supplied with vapor recovery line and particularly used to load volatile or toxic fluids into road tankers or railcars through a closed connection on the top of the tanker. It also performs recovery of highly volatile media.

Specifications

Nominal diameter: DN50~DN200 (liquid phase), DN50~DN100 (gas phase)

Design pressure: -0.06MPa~2.5MPa

Design temperature: -40℃~ 230℃

Pipeline material: carbon steel/stainless steel/PTFE lined

Drop pipe material: aluminum alloy or other materials

Features

- Pipe sections are connected by 4 swivel joints, providing the flexibility required for transporting fluids to any tankers located within the working envelope;

- When the height of the tanker is relatively high, then it is recommended to use a telescopic drop pipe that enables the tank to be filled from the bottom upwards;

- Installing a drop pipe deflector or cutting fill pipe off at 45 degrees can help minimize splashes and surges which may cause damage to the tank body;

- Equipped with inboard arm locking mechanism to lock the loading arm at parking position;

- Spring cylinder balancing system keeps the outboard arm and parts of front end counterbalanced, providing the loading arm with smooth up/down movement;

- Vacuum breaker is utilized to ensure that the piping system is quickly drained;

- Configured with anti-static device, efficiently eliminating the static charges and stray currents caused by liquid flowing through pipes during the loading and unloading operations;

- The loading arm is fitted with a cone to seal the manhole and a flexible vapor return hose for vapor recovery, avoiding leakage of hazardous materials;

- Outboard arm locking mechanism can be configured optionally to lock the loading arm at working position;

- Pressdown cylinder can be equipped to ensure a tight seal of the cone;

Optional Accessories

- Static grounding alarm

Grounding is an effective means of preventing the buildup of static charges by connecting the tanker to the earth. If connections are not made properly, the visible and audio alarm will be triggered. - Tank level alarm

When the liquid level exceeds the limited value, the alarm generates the sound or sends the signal to alert operators. - Submersible pump

The pump is used to discharge the liquids out of the tanker. - More configuration options

can be provided as per customer request.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos