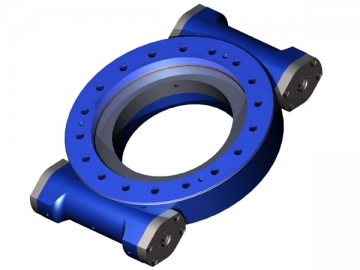

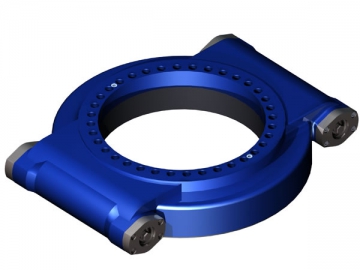

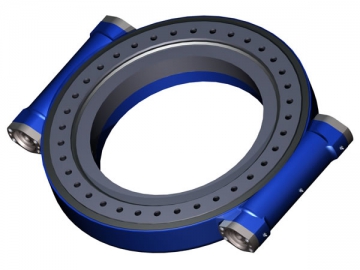

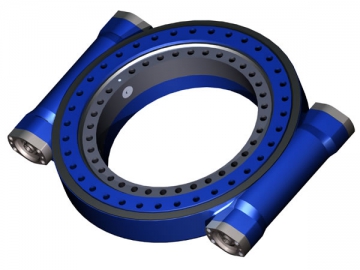

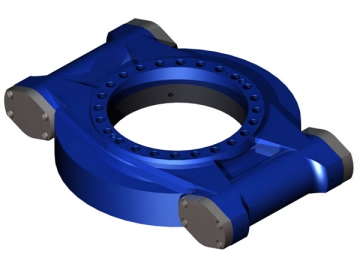

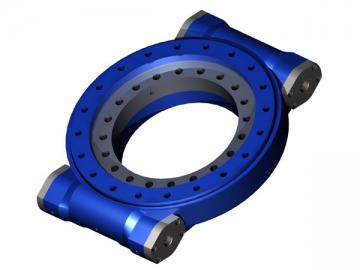

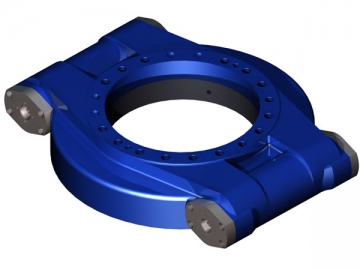

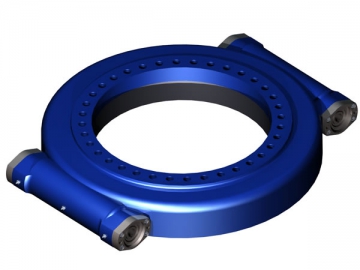

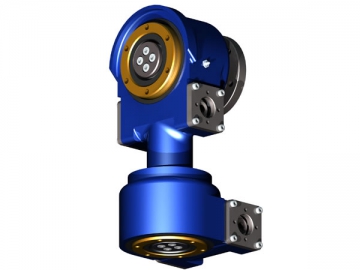

SE-2 Series Dual Worm Slewing Drive

Description

The SE-2 series slewing drive is composed of the vertical enclosed housing, slewing ring, 2 hourglass worms, and supporting components. Two electric or hydraulic motors can be used at the same time to drive the slew drive to rotate.

Compared with ordinary enclosed products, this dual worm slewing drive enjoys double tooth contact. In case of identical size and installation space, our worm gearing is able to produce nearly double output torque and the holding torque is increased correspondingly.

Advantages

1. The SE-2 series slewing drive is driven by two worms, so the contact teeth is more and the output torque is increased.

2. The tooth surfaces of the enveloping hourglass worms have been subjected to heat treatment, so the hardness of the worms is improved.

3. Our company starts producing this line of slewing drive from 2008. Technologies and processes have been very mature.

4. H-FANG gear reducer is highly recognized by customers in China, Europe, Americas, as well as other countries and regions.

Supply Capacity

Product customization service is available.

Application

The SE-2 series slewing drive is widely applied in the solar and machinery fields.

a. Horizontal drive in the photovoltaic or solar thermal power generation tracking system

b. Horizontal rotation and pitch angle rotation of drill rig

c. Rotation of console of cable winding and unwinding machine

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| | 12 kN•m | 67.8 kN•m | 48 kN•m | 555 kN | 222 kN | 133 kN | 117 kN | 85:1 | ≤ 0.17° | 76kg |

| 8851 lbf•ft | 50×103 lbf•ft | 35×103 lbf•ft | 125×103 lbf | 50×103 lbf | 30×103 lbf | 26×103 lbf |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| | 16.8 kN•m | 135.6 kN•m | 72.3 kN•m | 970 kN | 390 kN | 235 kN | 205 kN | 102:1 | ≤ 0.15° | 119kg |

| 12391 lbf•ft | 100×103 lbf•ft | 53×103 lbf•ft | 218×103 lbf | 88×103 lbf | 53×103 lbf | 46×103 lbf |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| | 20.6 kN•m | 203 kN•m | 105.8 kN•m | 1598 kN | 640 kN | 385 kN | 335 kN | 125:1 | ≤ 0.15° | 161kg |

| 15194 lbf•ft | 150×103 lbf•ft | 78×103 lbf•ft | 359×103 lbf | 144×103 lbf | 87×103 lbf | 75×103 lbf |

| Model | Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Gear Ratio | Tracking Precision | Weight |

| | 28 kN•m | 271 kN•m | 158.3 kN•m | 2360 kN | 945 kN | 590 kN | 470 kN | 150:1 | ≤ 0.15° | 222kg |

| 20652 lbf•ft | 200×103 lbf•ft | 117×103 lbf•ft | 531×103 lbf | 212×103 lbf | 133×103 lbf | 106×103 lbf |