Oilless Self-lubricating Bearing

Brief Introduction

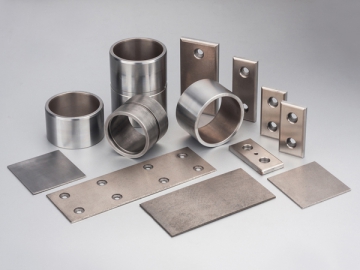

The oilless self-lubricating bearing is a composite bearing that consists of steel backing and wear-resistant porous materials. The special wear-resistant layer is formed by sintering the copper alloy powder and graphite-based solid lubricant dispersed on a metal base at high temperature. It has gone through special oil-containing treatment.

A solid lubricant is uniformly distributed inside an alloy layer, so it can form a solid lubricant film at the beginning of sliding. With low shear strength, the film can be firmly adhered to the surface of the oilless self-lubricating bearing without cracking under ultra high static load. Therefore, the phenomenon of crawling will not occur under microscopic movement. The metal base provides ultra high mechanical strength and dimensional stability, so as to obtain distinguished friction and wear characteristics.

Features

1. Uniform dispersion of solid lubricant allows the oilless self-lubricating bearing to be used under friction condition from any direction. Also, superb performance of fretting wear resistance is provided.

2. As a kind of engineering machinery bearing, this product can be used without oil.

3. High load, excellent wear resistance, and unexceptionable speed characteristic

4. We can supply standard goods and different specifications of plates used for secondary processing.

DERNORE is a veteran steel-backed bearing manufacturer. As the processing cost increasingly rises, each company is unceasingly reducing production cost so as to maximize the benefits.

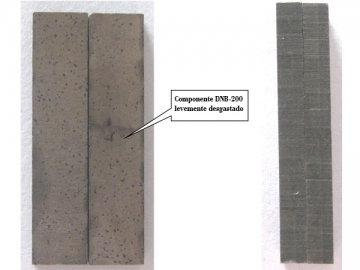

Our company has developed the new kind of DNB-#200 oilless self-lubricating bearing to replace DNB-#50 traditional type. This new product can achieve the same wear-resisting property as that of DNB-#50 type. Also, it is resistant to dust, corrosion and impact. It performs well in various industries including the injection molding machines, tire moulds, and the engineering machinery (such as excavator, etc).

The DNB-#200 oilless self-lubricating bearing shows better lubricating property when compared to DNB-#50 type. Its entire surface is lubricated, so it is difficult to form oil film in the reciprocating motion, rocking motion, and the frequent start, etc. Its wear-resisting property is much better.

Physical and Chemical Properties

| Max. P | Dry friction | Dynamic load | N/m·m² | 24.5 |

| Regular oiling /geschmiert | 49 | |||

| - | Static load/slight movement | 100 | ||

| Max. V | Dry friction | m/s | 0.5 | |

| Regular oiling/geschmiert | 1 | |||

| Max. Pv | Dry friction | N/mm²·m/s | 1.63 | |

| Regular oiling/geschmiert | 2.65 | |||

| Service Temperature Range | ℃ | -40~ 400 | ||

| Hardness | HB | >45 | ||

Parts No.

Application

- Bridge

- Sanitation Equipment

- Petroleum Machinery

- Mining Truck

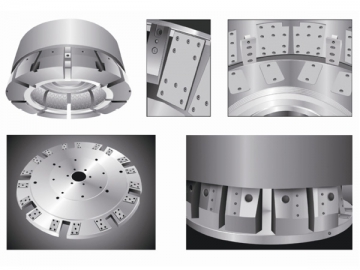

- Tire Mould

- Hydraulic Metal Working

Machinery - Injection Molding Machine

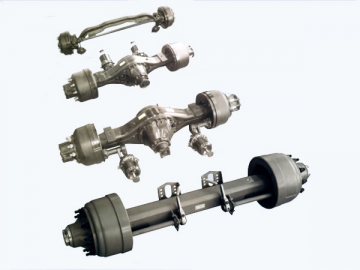

- Vehicle Axle