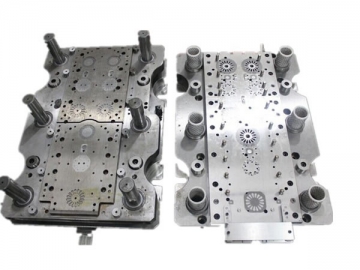

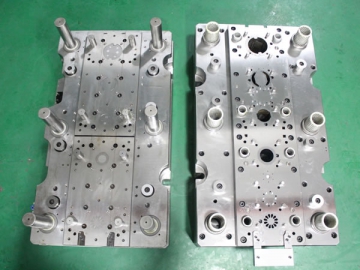

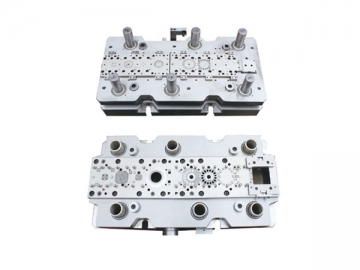

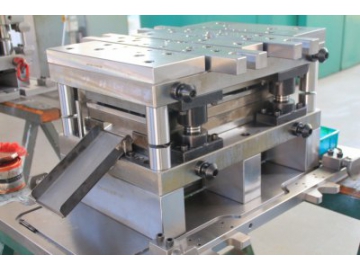

Progressive Dies (Stamping Dies for Motor Laminations)

Iron cores are the heart of motors, and are most often made using progressive dies. The quality of the motor core directly links to the overall torque and power of the complete engine. Due to that many manufacturers and car factories install high performance stamping dies and press dies in their machine presses for a fast batch production of quality iron cores.

We are a professional Chinese die maker established in 1997, and we are committed to providing different varieties of progressive dies to motor manufacturers around the world. We have provided them with stamping dies typically used for producing iron cores in universal motors, shaded pole motors, motors with capacitors, and brushless motors. Our expertise also helps iron core manufacturers simplify the iron plate lamination process by introducing automatic double row stacking technology. When compared to dies used in a single acting press or a progressive stamping die, this new stacking technology eliminates the process of manual welding or riveting motor laminations into a full stack, reducing labor costs associated with iron core production.

The following list is key details related to the design and manufacturing of progressive dies.

1. Built-to-Order Stamping Dies

Standard Frame: 45#, 50#

Bolster plate: SKD11

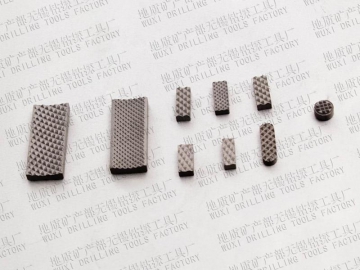

Cutting edges, insert s, hard alloys

Material to be stamped: silicon steel 50W400

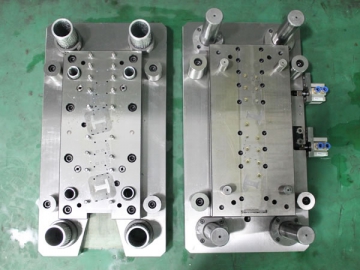

2. Manufacturing Method of the Press Tool

Surface grinding-watermill

CNC-machining center

EDM-wire cut EDM

WEDM-wire cut WEDM (Sodick brand, both fast and slow speed configuration options)

3. Inspection of Die Components

2D image measuring instruments, high precision micro-caliper, standard caliper, various other measuring devices

4. Features of Progressive Dies

Automatic dual-row stacking

Withstands repeated use-up to 100 million uses.

Cutting edges need grinding every 2 million uses.

Easy assembly and disassembly

Allows for convenient modifications and low repair costs

For more information on these progressive dies, please feel free to contact us.